3d Printing In Manufacturing Challenges And Advantage Vrogue Co

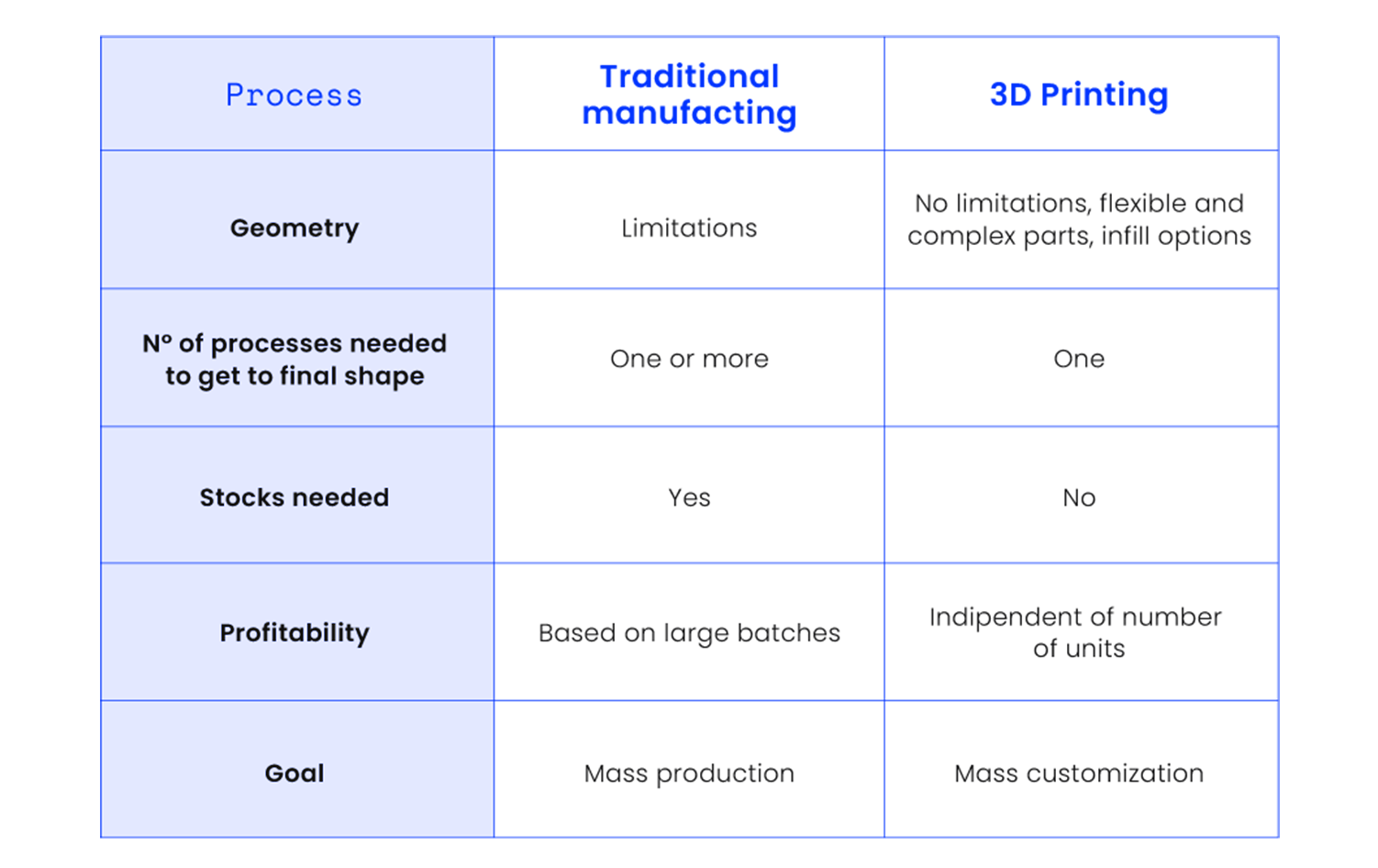

3d Printing In Manufacturing Challenges And Advantage Vrogue Co 4. complex designs. 3d printing allows for the creation of complex geometries that are either impossible or prohibitively expensive with traditional methods, opening up new possibilities in design and functionality. 5. supply chain simplification. by enabling on demand production closer to the point of use, 3d printing can significantly reduce. Scaling difficulties (5.75 average): as businesses attempt to move from prototyping or small scale production to larger volumes, they encounter challenges in scaling 3d printing processes efficiently.

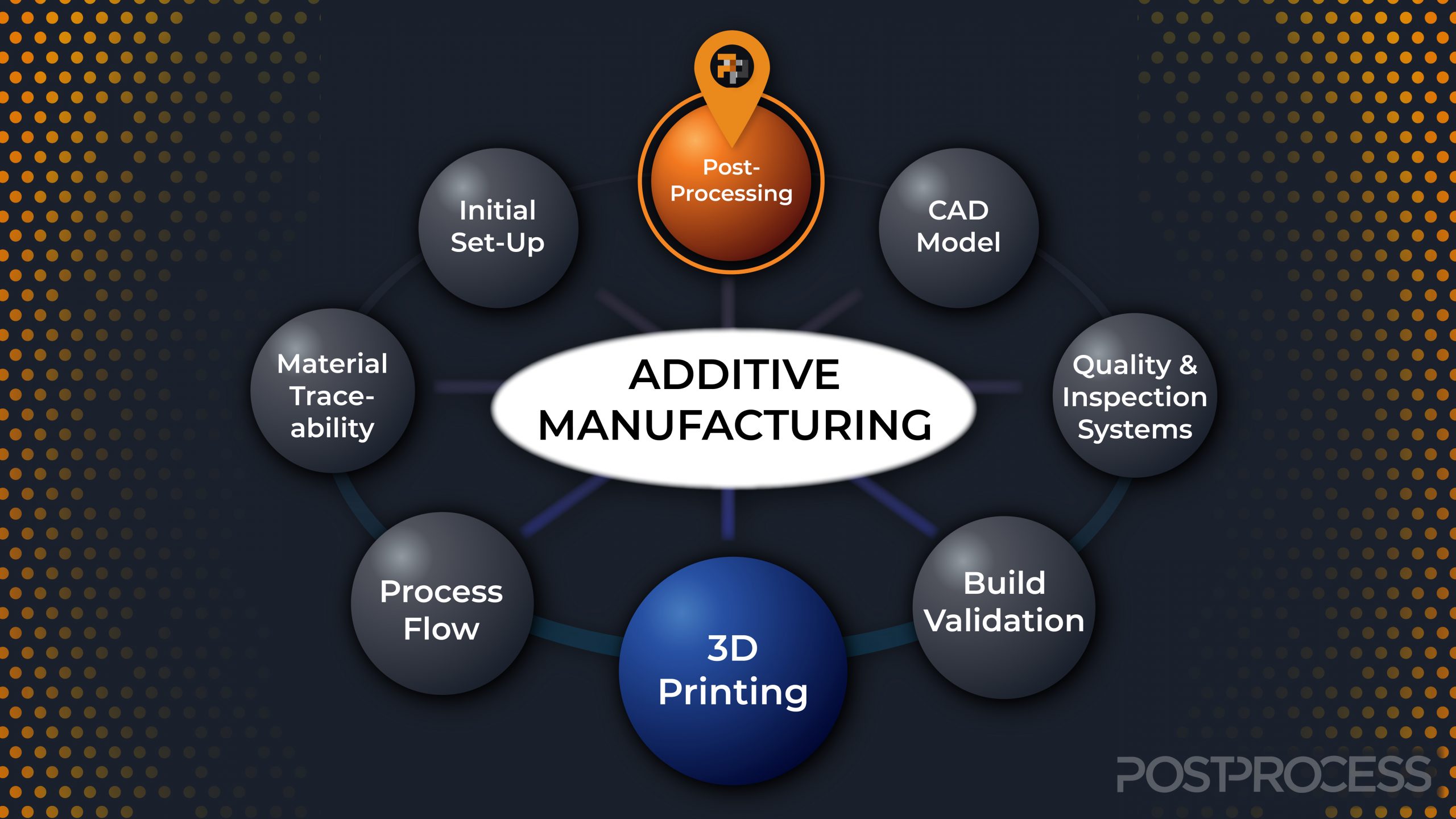

3d Printing In Manufacturing Challenges And Advantage Vrogue Co Daniel princ, head of production, p3 emea & apac at stratasys, explores the many advancements in 3d printing & how it is transforming production technology. one of the biggest buzzwords in the 3d printing additive manufacturing (am) industry is ‘production’. the technologies that make up the am ecosystem have for over 30 years established. In the manufacturing industry, 3d printing has been adopted in various ways. one of the most significant advantages is the ability to produce goods as they are sold, reducing overproduction and storage costs. this just in time manufacturing approach can lead to significant cost savings and efficiency improvements. In conclusion, the future of 3d printing lies in creating more automated, sustainable, and application focused solutions. the anticipated market recovery in the next 18 24 months will likely be a. Several benefits can be gained by using additive manufacturing (am) or 3d printing, including design flexibility, mass customization, waste minimization, quickly producing complex structures, and rapid prototyping. the standard methods and materials used in 3d printing, along with their development and use, have been examined.

3d Printing Vs Traditional Manufacturing Differences Vrogue Co In conclusion, the future of 3d printing lies in creating more automated, sustainable, and application focused solutions. the anticipated market recovery in the next 18 24 months will likely be a. Several benefits can be gained by using additive manufacturing (am) or 3d printing, including design flexibility, mass customization, waste minimization, quickly producing complex structures, and rapid prototyping. the standard methods and materials used in 3d printing, along with their development and use, have been examined. Besides print precision, the primary hurdles for 3d printing ceramics are layer by layer aesthetics and a restricted number of materials [91]. post processing sintered ceramic pieces to get the correct shape is a expensive and time consuming operation. 3d printing of complicated forms for generate complex shaped ceramics is becoming quite. At jabil's auburn hills site, using 3d printing for jigs and fixtures has led to a time reduction of 80% (from months to weeks) and up to 30% reduction in tooling costs. with additive manufacturing, a fan within an aircraft cooling system can be consolidated from 73 labor intensive and time consuming parts to one.

12 Advantages Of 3d Printing In Manufacturing Talk Business Besides print precision, the primary hurdles for 3d printing ceramics are layer by layer aesthetics and a restricted number of materials [91]. post processing sintered ceramic pieces to get the correct shape is a expensive and time consuming operation. 3d printing of complicated forms for generate complex shaped ceramics is becoming quite. At jabil's auburn hills site, using 3d printing for jigs and fixtures has led to a time reduction of 80% (from months to weeks) and up to 30% reduction in tooling costs. with additive manufacturing, a fan within an aircraft cooling system can be consolidated from 73 labor intensive and time consuming parts to one.

Exploring The Impact Of 3d Printing On Manufacturing Advantages

Comments are closed.