7 Types Of Service Valve And Their Uses

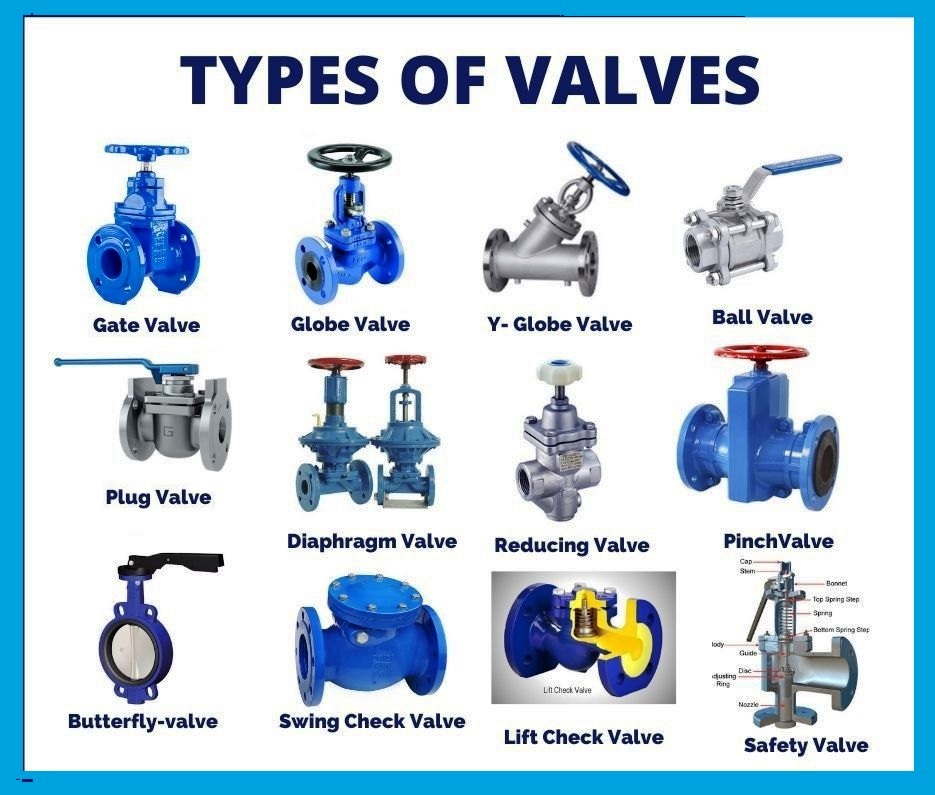

Valves The Types How They Operate And Where They Are Used Conclusion. in conclusion, choosing the right type of service valve can significantly impact the effectiveness of your pipeline system. gate valves, globe valves, ball valves, butterfly valves, and check valves are the market’s most commonly found service valves. each has unique features that make them ideal service valves for specific purposes. There are two types of diaphragm valves: weir type and straight through type. it is necessary for weir type diaphragm valves to have relatively low thrust and shut off strokes. this prolongs the diaphragm’s life. the straight through type diaphragm valve can handle slurries, viscous liquids, and fibrous suspensions.

7 Types Of Service Valve And Their Uses Types of valves. in piping following types of valves are used depending on the requirements. the cost of valves in the piping system can be up to 20 to 30% of the overall piping cost. and the cost of a given type and size of valve can vary 100%. it means that if you choose a ball valve over a butterfly valve for the same function. it can cost. To engage a service valve safely, first ensure the hvac system is powered off. locate the service valve and remove the protective cap. use a specialized hvac wrench to turn the valve stem clockwise until it stops. this opens the valve, allowing refrigerant flow. it’s vital to open valves slowly to prevent damage. Valves are an essential part of any piping system conveying liquids, vapors, slurries, gases, mixtures of liquid, and gaseous phases of various flow media. valves are the most costly rigid piping components in a plant. they can account for up to 20% to 30% of overall piping item costs for a process plant. the size of a valve is decided by the. These valves are available in various sizes of ranging from 6mm to 600 mm. the construction of material can be cast iron, steel, ductile iron, and corrosion resistant alloys. #4. plug valve: the plug valve is a quarter turn rotary valve. in this, the disc rotates in a circular motion and uses valves to open or close.

Comments are closed.