Air Barrier Systems International Masonry Institute

Air Barrier Systems International Masonry Institute The rainscreen certificate program covers the role of craftworkers in the overall execution of a rainscreen wall project, including the theory and history behind the rainscreen movement and an in depth understanding of materials methods and advancements in rainscreen technology. the learning modules actively engage masonry craftworkers – many. The whole building's air leakage rate must not exceed 2 l s.m² 75 pa (0.4 cfm sf 1.57 psf) when tested according to astm e779. the air barrier system must be able to withstand the maximum design positive and negative air pressure and must transfer the load to the structure.

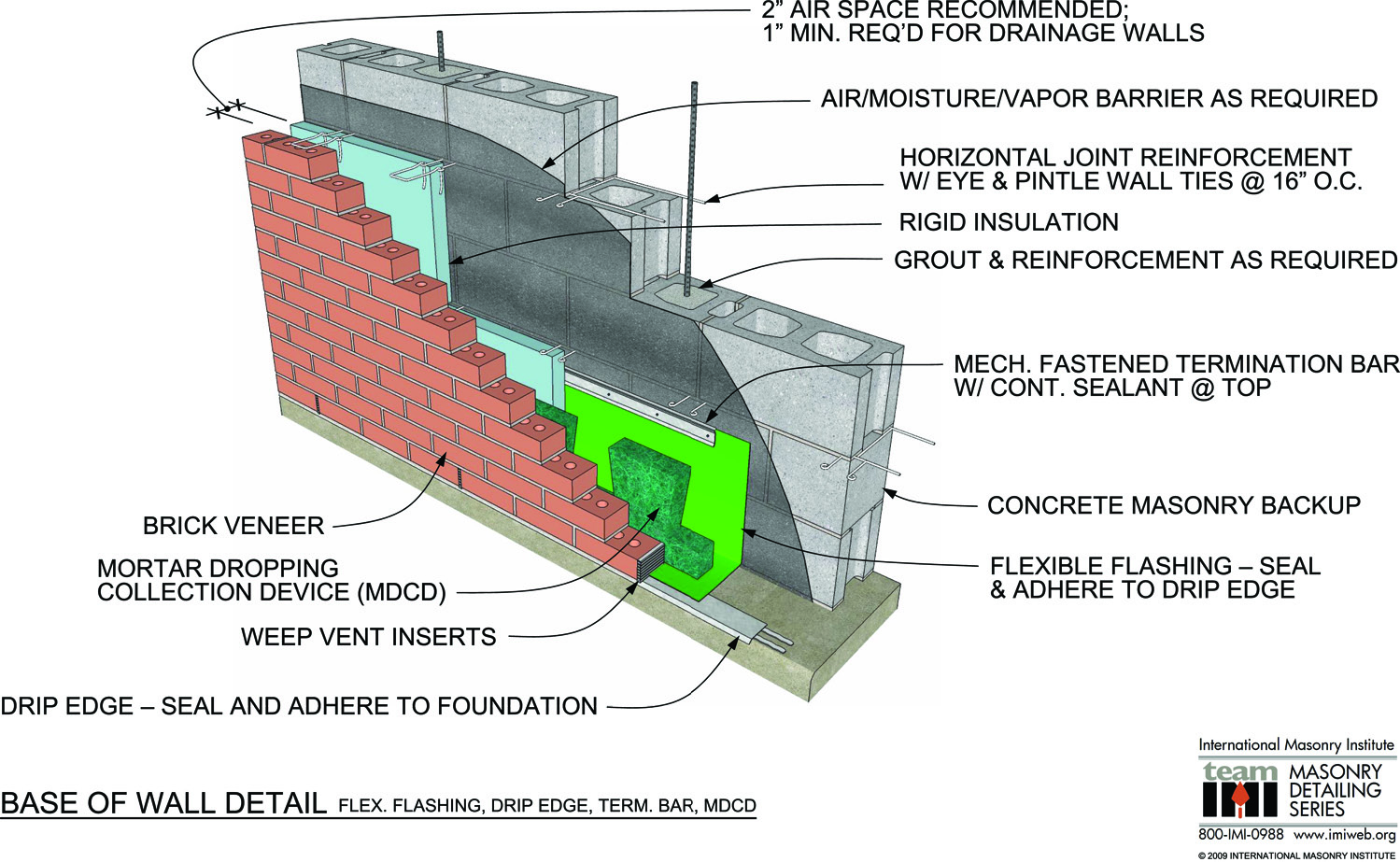

Air Barrier Systems International Masonry Institute The main components of ventilated cavity walls are: a vented cladding, air space behind the cladding, air barrier on the exterior side of the support wall, and through wall flashing. if there is wall cavity insulation, then the insulation should be made continuous at joints and penetrations with tape, spray foam, or other means so air is not. Wall systems started to become less massive, due to better material strength, improved . figure 2 – modern masonry cavity wall detail from international masonry institute’s . masonry detailing series, imiweb.org. figure 1 – example of a mass masonry wall from the late 19th century. m. a r c h . 2016 i. n t e r f a c e • 23. Air barrier systems can increase exterior building envelope performance, which makes them a timely topic, as people think green and states consider stronger codes and enforcement. yet, while they are common in canada, u.s. designers are on a learning curve, especially when it comes to understanding the differences between air barriers and vapor. An air barrier material is a material that has a maximum air leakage rate of 0.004 cfm ft2 at a pressure difference of 1.57 psi [ .02 l (s m 2 ) ] at a pressure difference of 75 pa ) when tested in accordance with astm e2178.

Comments are closed.