Aircraft Oil And Cooling Systems Aerotoolbox

Aircraft Oil And Cooling Systems Aerotoolbox This is an oil designed for to be used when the aircraft is operated in a temperate climate (15°c – 30°c). temperature has a large effect on the viscosity of the oil. cooler temperatures result in the viscosity increasing (more difficult to pour) and warmer temperatures cause the viscosity to drop (easier to pour). Aircraft oil and cooling systems internal combustion engines must be adequately lubricated and cooled while running in order to provide safe operation and to function as intended. andrew wood.

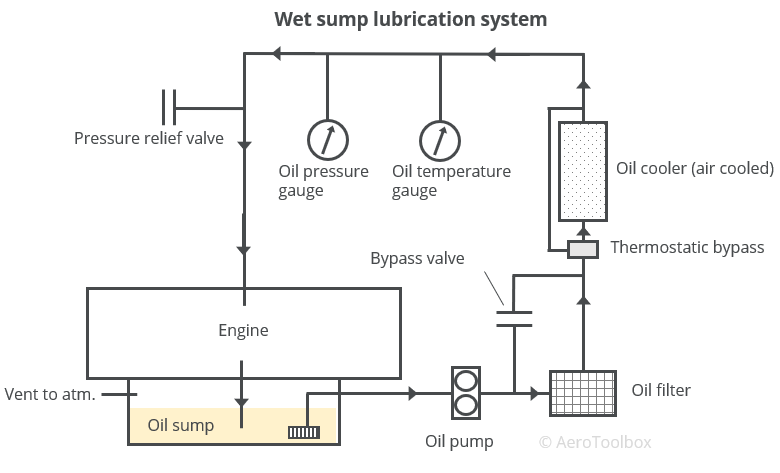

Aircraft Oil And Cooling Systems Aerotoolbox So long as the engine is running, the oil pump will continue to operate, keeping the engine lubricated. the pressure in the oil system is monitored by the pilot through an oil pressure gauge in the cockpit. the oil system and cooling of aircraft engines is covered in more detail in a dedicated lubrication and cooling post. fuel system. Federal aviation administration. 800 independence avenue, sw. washington, dc 20591. 866.835.5322 (866 tell faa) contact us. The airflow systems x series are the first light aircraft oil cooler design in 50 years. computer modeling and flight testing have been used to develop coolers that deliver significantly lower oil temps with no increase in oil cooler size or oil pressure drop. designed as a direct replacement for popular oil coolers used in experimental. Introduction: lubrication systems are responsible for lubrication, heat management, and collecting debris. wet and dry lubrication systems keep aircraft well oiled while maintaining proper operating temperature. depending on the aircraft, oil also powers other systems and accessories.

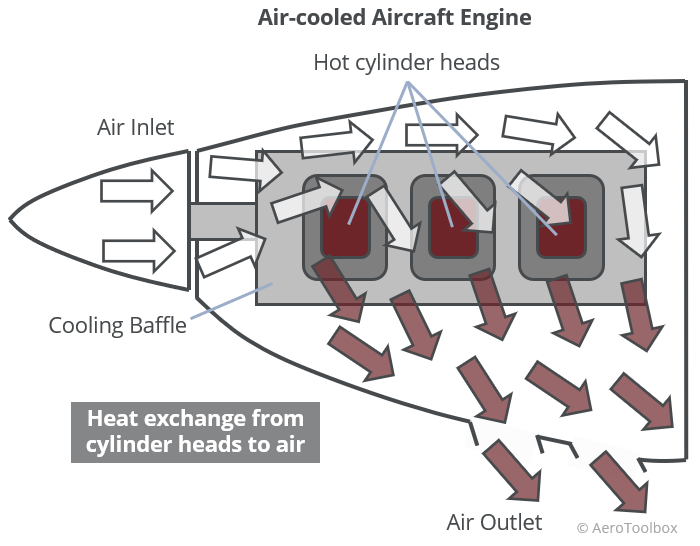

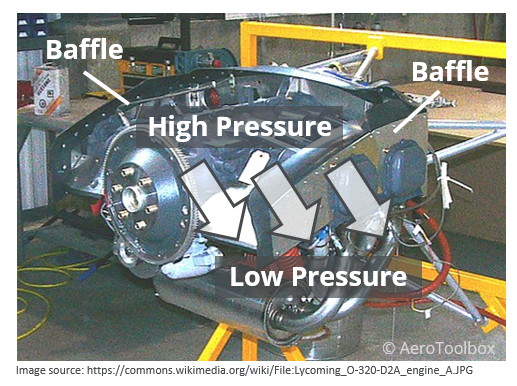

Aircraft Oil And Cooling Systems Aerotoolbox The airflow systems x series are the first light aircraft oil cooler design in 50 years. computer modeling and flight testing have been used to develop coolers that deliver significantly lower oil temps with no increase in oil cooler size or oil pressure drop. designed as a direct replacement for popular oil coolers used in experimental. Introduction: lubrication systems are responsible for lubrication, heat management, and collecting debris. wet and dry lubrication systems keep aircraft well oiled while maintaining proper operating temperature. depending on the aircraft, oil also powers other systems and accessories. As for cooling, oil provides up to 40 percent of an aircraft's air cooled engine's cooling. oil creates a seal between piston rings and cylinder walls. aviation multigrades developed later. The integration of oil cooling and fuel heating in fcocs leads to a reduction in the complexity of the aircraft's fluid circulation system. with fewer components involved, there is a decrease in the need for extensive piping and connections, further contributing to weight savings and simplifying the overall layout.

Aircraft Oil And Cooling Systems Aerotoolbox As for cooling, oil provides up to 40 percent of an aircraft's air cooled engine's cooling. oil creates a seal between piston rings and cylinder walls. aviation multigrades developed later. The integration of oil cooling and fuel heating in fcocs leads to a reduction in the complexity of the aircraft's fluid circulation system. with fewer components involved, there is a decrease in the need for extensive piping and connections, further contributing to weight savings and simplifying the overall layout.

Comments are closed.