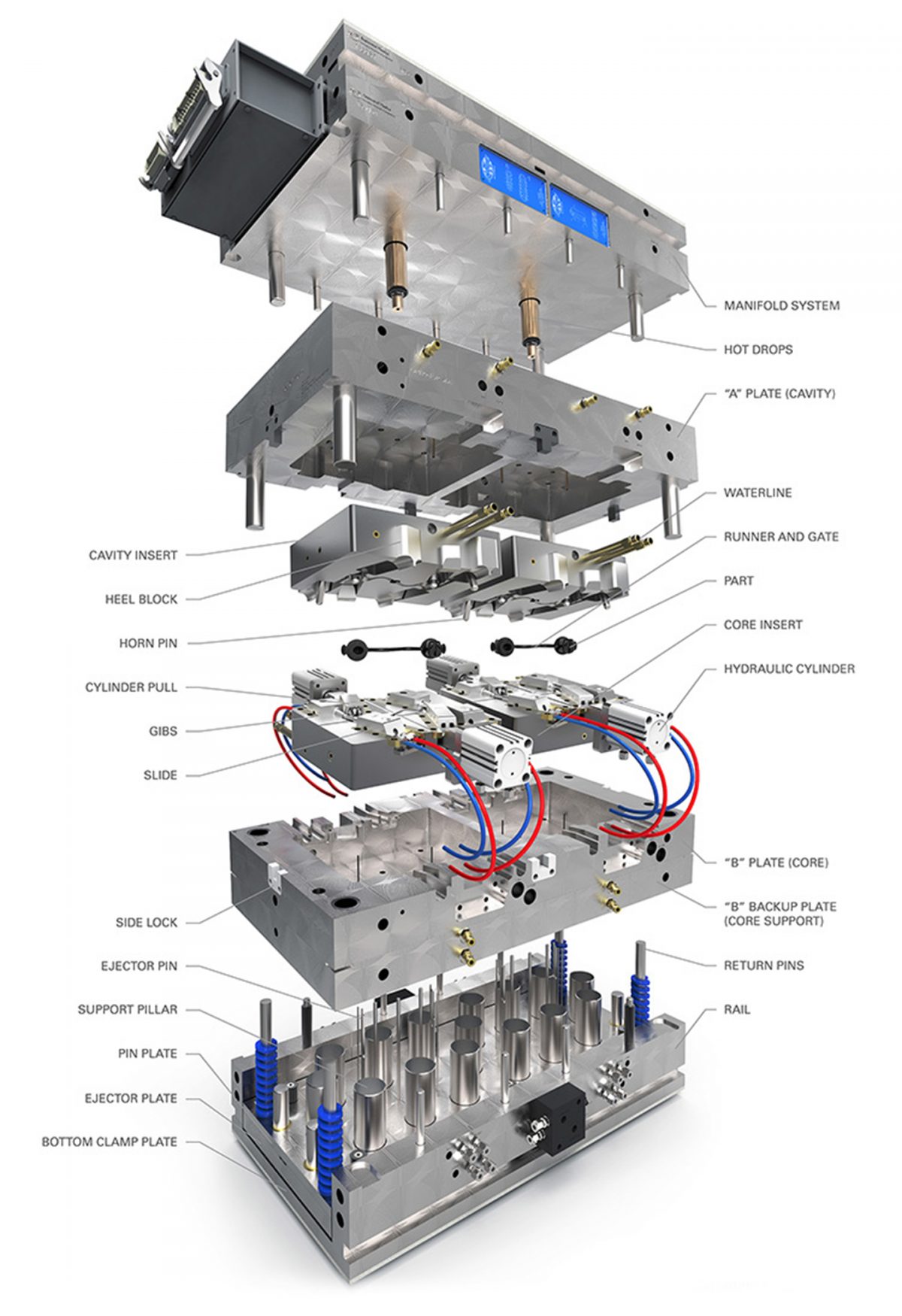

Anatomy Of A Mold Pti Plastic Injection Molding

Anatomy Of A Mold Pti Plastic Injection Molding How a plastic injection mold works. 50900 corporate drive macomb, michigan 48044 1 (586) 263 5100. The basic structure of an injection mold includes several key components: clamp plates: secure the mold halves to the molding platens. nozzle sprue bushing: directs molten plastic into the mold. feed system: channels plastic through sprues and runners to the cavities. cavities: form the desired part shapes.

One Picture To Understand The Structure Of An Injection Mold Introduction welcome to the fascinating world of injection molding! at the heart of this process lies the mold – a complex and precision engineered tool that transforms raw plastic into a vast array of products. understanding the anatomy of an injection mold is crucial for anyone in the field of manufacturing and product design. today, we’ll dissect the mold piece by piece, giving you. The basics of injection molding. before diving into the components, it’s essential to understand the basics of injection molding. at its core, injection molding is a process where molten material, often plastic, is injected into a mold cavity. once inside, the material cools and solidifies, taking the shape of the cavity. High volume manufacturing of plastics injection molding is the most cost competitive technology for manufactur ing high volumes of identical plastic parts. once the mold is created and the machine is set up, additional parts can be manufactured very fast and at a very low cost. the recommended minimum production volume for injection molding is 500. The future of medical device manufacturing is being molded with precision, and injection molding is at the forefront of this revolution. our medical plastic injection molding capabilities include: medical device design development and assistance. design for manufacturability. medical device molding. cleanroom molding and assembly, class 8.

Comments are closed.