Case Study Ge Power Generation Gas Turbine Transition Ducts

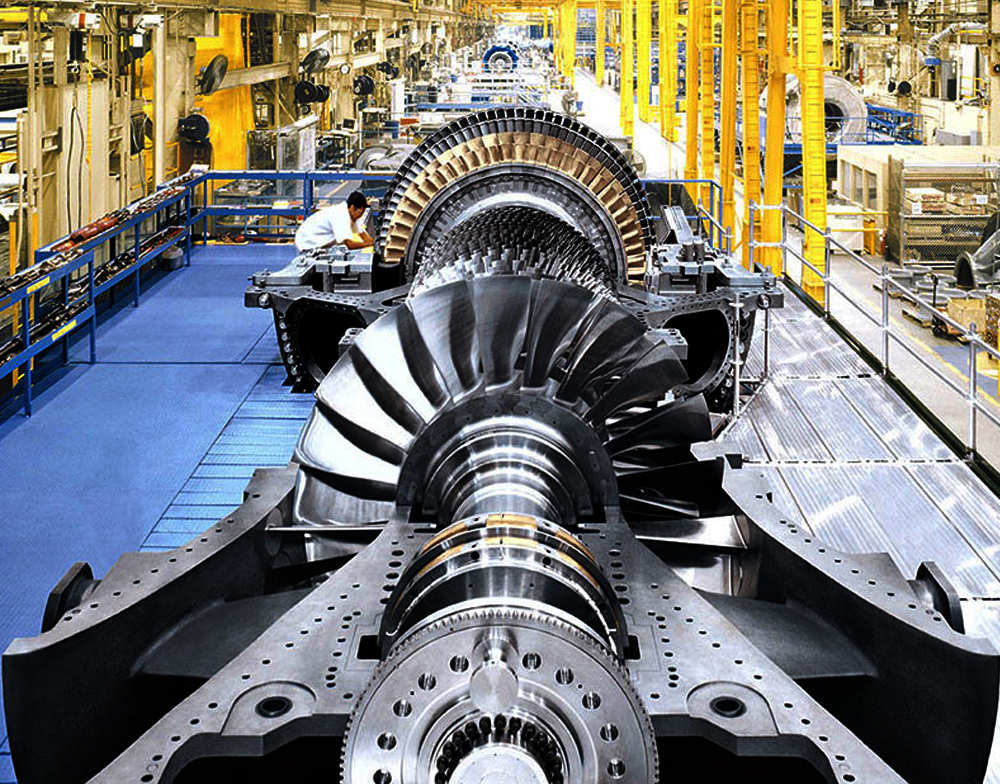

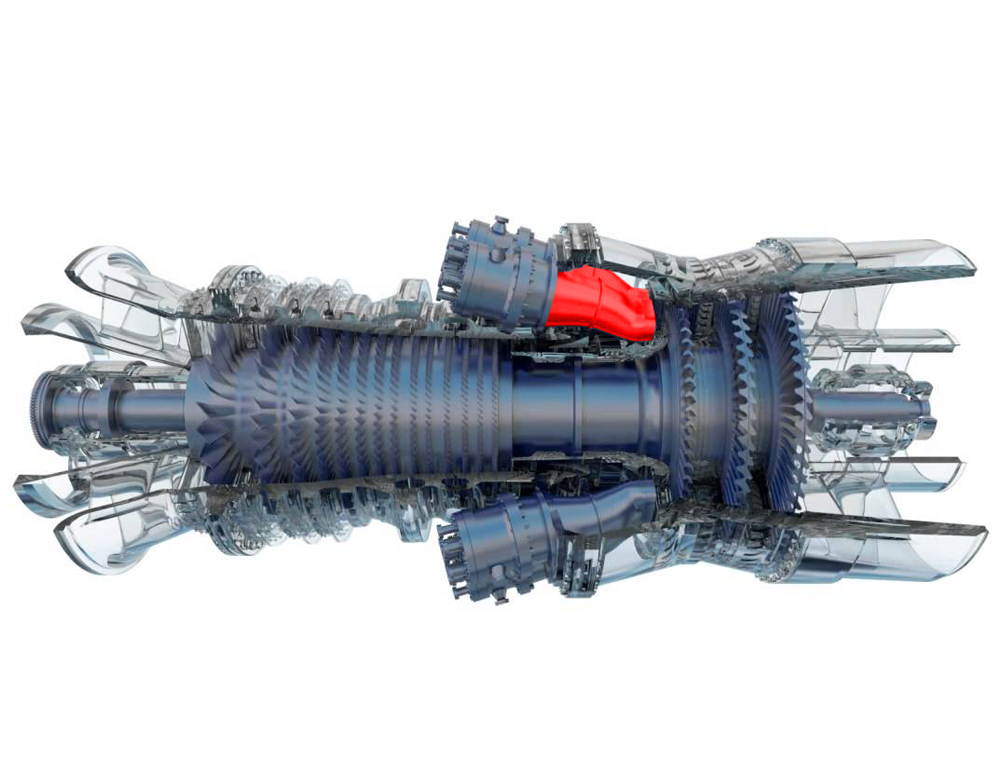

Case Study Ge Power Generation Gas Turbine Transition Ducts The combustion produces a high temperature, high pressure gas stream that enters and expands through the turbine’s transition duct section. with the following turbine, it makes up the hot section. the turbine is an intricate array of alternate stationary and rotating aerofoil section blades. as hot combustion gas expands through the turbine. Ceo, of rwe generation. rwe’s new 300 mw plant was built just south of the company’s current nuclear power plant site in the region and began operation in march 2023. ge’s lm2500xpress g5 dle power plant is built on ge’s proven lm2500 aeroderivative gas turbine technology. with more than 2,500 units sold and more than 100 million.

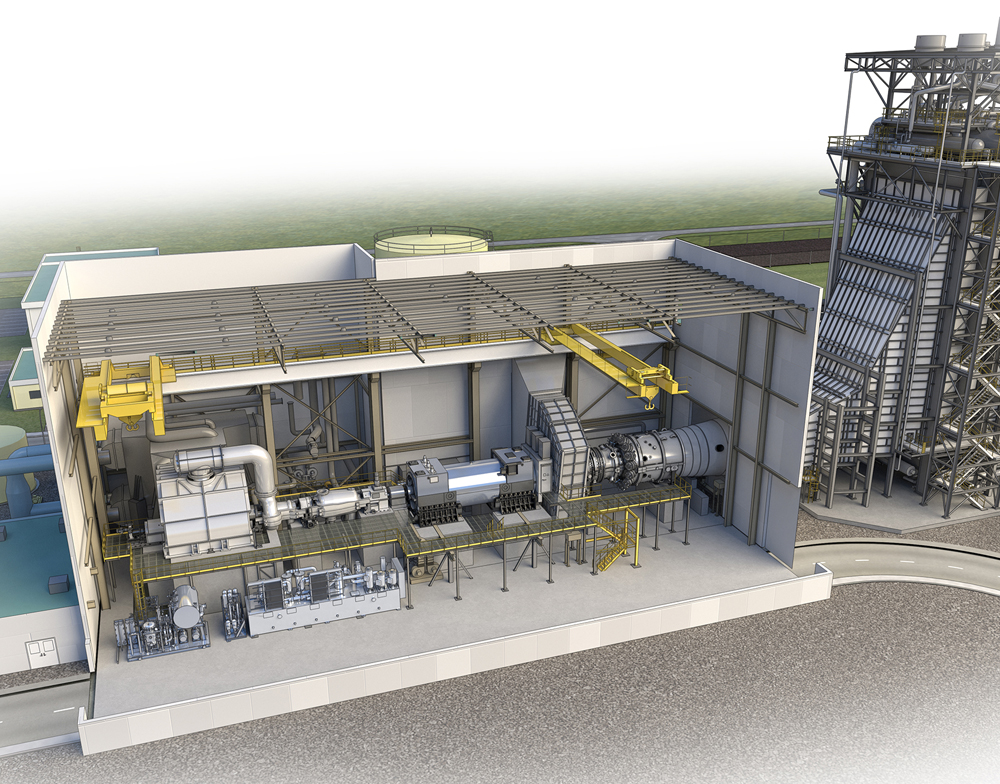

Case Study Ge Power Generation Gas Turbine Transition Ducts The plant utilizes a ge 7ha.02 combustion turbine, which can burn between 15 20% hydrogen by volume in the gas stream initially, with the capability to transition to 100% hydrogen over time. “this is a profound achievement for long ridge energy terminal, ge, and the entire power generation industry. Case study. ge’s tm2500 accelerates diesel to gas transition in yemen. ge vernova's “power plant on wheels” tm2500 mobile gas turbine will help yemen’s petromasila transition from diesel to natural gas based power generation. The importance o gas fired generation in a transormed energy landscape 4 case study: the world’s first hybrid battery gas turbine power plant in 2017, southern california edison (sce)—which provides 15 million residents with energy in the greater los angeles area—launched the world’s first hybrid battery gas turbine power plant. Power systems mfg. llc (psm) discusses best practices in transition piece design to allow aerodynamic pieces that optimize and combine improved cooling effectiveness with low pressure drop and reduced emissions operation. the transition piece (tp) is a critical part of a gas turbine, leading the hot gas from the combustion chambers to the.

Case Study Ge Power Generation Gas Turbine Transition Ducts The importance o gas fired generation in a transormed energy landscape 4 case study: the world’s first hybrid battery gas turbine power plant in 2017, southern california edison (sce)—which provides 15 million residents with energy in the greater los angeles area—launched the world’s first hybrid battery gas turbine power plant. Power systems mfg. llc (psm) discusses best practices in transition piece design to allow aerodynamic pieces that optimize and combine improved cooling effectiveness with low pressure drop and reduced emissions operation. the transition piece (tp) is a critical part of a gas turbine, leading the hot gas from the combustion chambers to the. Abstract. the gas turbine twin shaft variant requires an aerodynamic coupling between its high pressure gas generator module and low pressure power module. these two modules are spaced apart for aerodynamic and mechanical reasons. typically, this is achieved by having a transition duct (td) in between these two modules which smoothly allows the gas flow from hp turbine to lp turbine. to. Performance intelligence: near real time thermal advisory solution to improve plant efficiency. achieve a .5 1% heat rate reduction. reduce fuel use by operationalizing heat rate with advanced physics based digital twins, combined with actionable recommendations. by reducing fuel use, emissions inherently go down and help in the attainment of.

Case Study Ge Power Generation Gas Turbine Transition Ducts Abstract. the gas turbine twin shaft variant requires an aerodynamic coupling between its high pressure gas generator module and low pressure power module. these two modules are spaced apart for aerodynamic and mechanical reasons. typically, this is achieved by having a transition duct (td) in between these two modules which smoothly allows the gas flow from hp turbine to lp turbine. to. Performance intelligence: near real time thermal advisory solution to improve plant efficiency. achieve a .5 1% heat rate reduction. reduce fuel use by operationalizing heat rate with advanced physics based digital twins, combined with actionable recommendations. by reducing fuel use, emissions inherently go down and help in the attainment of.

Comments are closed.