Cci Shall Cu Ccsurvive Cu Ccusing Cu Ccpotions Cu O O Oo O Co Io O Oo No Eo O O Ccpv Cu 2 O Eo O Oo

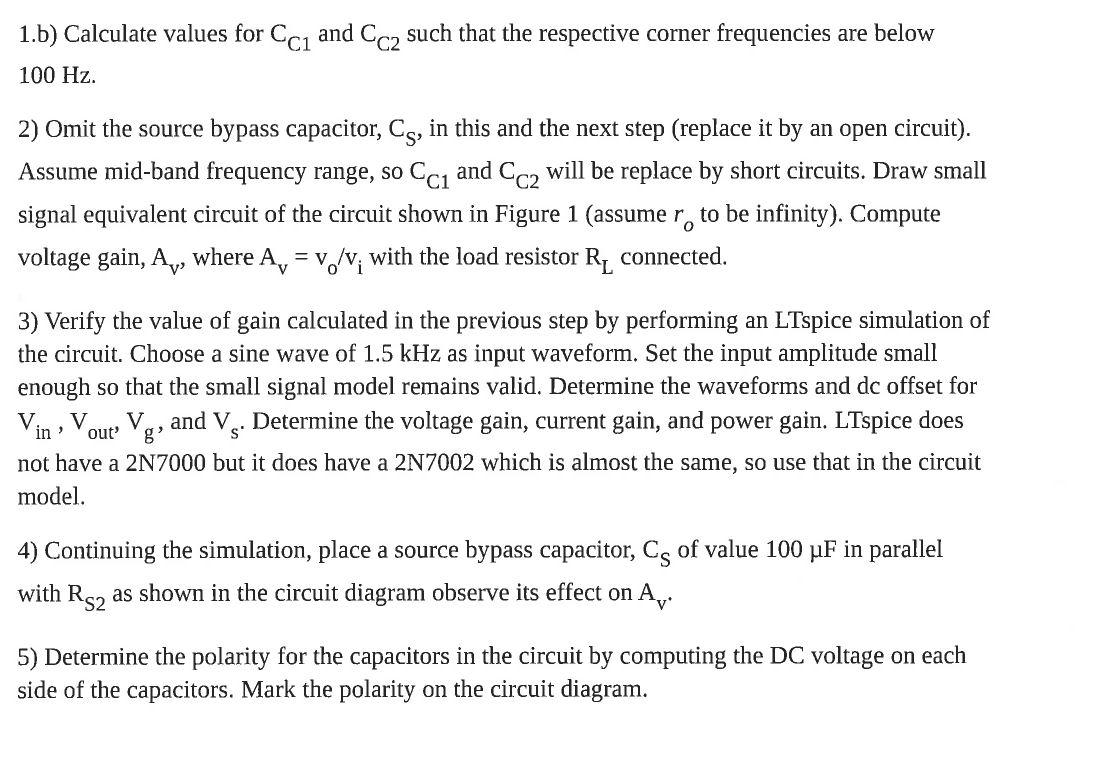

1 B Calculate Values For Cci And Cc2 Such That The Chegg Uniform capping ligands free cu 2 o ncs, including cubic cu 2 o ncs (c cu 2 o) enclosed with {100} crystal planes with different size distributions of 682 ± 92 (denoted as c cu 2 o 682), 109 ±. A, b xrd patterns of a cu 3 (po 4) 2 and b cu 2 p 2 o 7 before and after co 2 rr at the potential of −1.40 v, indicating the coexistence of cupo and metallic cu components in both cu 3 (po 4) 2.

Cu Forms Two Oxides Cuprous And Cupric O Xide Which Law Can Be Proved Copper (cu), a promising catalyst for electrochemical co 2 reduction (co 2 r) to multi electron reduction products, suffers from an unavoidable and uncontrollable reconstruction process during the reaction, which not only may lead to catalyst deactivation but also brings great challenges to the exploration of the structure–performance relationship. The cu 2 o (111) and cu (111) surfaces are used for comparison. as reported in the literature, the co is reduced from co 2 first. 34, 55, 56 the ∗co adsorbs on the cu 0 cu interface and cu 2 o (111) surface by the top site, while ∗co adsorbs on the cu (111) by the hollow site (figure 5 a). Therefore, the development of efficient electrocatalysts and investigation of corresponding reaction mechanisms are critically important. herein, an efficient dendritic cu 2 o cu grown on cu foam (d cu 2 o cu cf) has been synthesized by a facile electrodeposition method, and the synergetic effect of cu and cu in no 3 – rr has. Co 2 hydrogenation. the performance of co 2 hydrogenation was evaluated in a batch stainless steel reactor with 10 mg catalyst and 10 ml water. commercial cu zno al 2 o 3, c 3 n 4, and cu nps c 3.

Ppt 9 26 11 Powerpoint Presentation Free Download Id 4270814 Therefore, the development of efficient electrocatalysts and investigation of corresponding reaction mechanisms are critically important. herein, an efficient dendritic cu 2 o cu grown on cu foam (d cu 2 o cu cf) has been synthesized by a facile electrodeposition method, and the synergetic effect of cu and cu in no 3 – rr has. Co 2 hydrogenation. the performance of co 2 hydrogenation was evaluated in a batch stainless steel reactor with 10 mg catalyst and 10 ml water. commercial cu zno al 2 o 3, c 3 n 4, and cu nps c 3. During the formation of c 2 h 6 o 2, *cho produced via the protonation of *co is further inserted into *co to generate c 2 h 2 o 2 and ultimately c 2 h 6 o 2. as mentioned above, cu electrocatalysts feature moderate binding strengths for most c based intermediates and limited by scaling relationships, therefore exhibiting poor selectivity. As fuel and an important chemical feedstock, n propanol is highly desired in electrochemical co2 co reduction on cu catalysts. however, the precise regulation of the cu localized structure is still challenging and poorly understood, thus hindering the selective n propanol electrosynthesis. herein, by decorating au nanoparticles (nps) on cuo nanosheets (nss), we present a counterintuitive.

Comments are closed.