Ccwishing Cu Ccon A Star Cu Ccbts Cu Uy O O Aeo Oou Ccenglish Cu Cclyrics Cu Youtube

Play Doh How To Make A Rainbow Star Cu Kids Youtube Cu carbon nanotube (cnt) composites that merge copper with cnts are touted to fulfil the growing need for cu substitutes [8 – 17]. cnts are expected to play two roles in cu cnt. (i) made of carbon, cnts act as weight reducers, rendering the composites lighter. (ii) cnts could transmit their own exceptional nanoscale multifunctional properties. Cnt cu composites can be fabricated by two routes, (i) powder based mixing and compaction of cnts and cu 5,6,7,8,9,10,11,12,13 or (ii) cu electrodeposition on into cnt assemblies 1,2,3,4, 14,15,16.

Fesem Micrographs Of Cu 4 Vol Cnts Nanocomposites Sintered At The cu coated cnts along with fine cu powder were produced by wet chemical route by reducing the metal precursor cuso 4.5 h 2 o, in the presence of ctab and mcnts under the reducing environment of naoh and nabh 4. this process was conducted while maintaining the ph (12) and temperature at 5–8 °c. To further confirm the cu species and its content on cnts surface, xps analysis was carried out (fig. 3). fig. 3 a shows the xps result of cnts cuo, from which c, o and cu can be easily detected, according to the surface element analysis, the content of c, o and cu is 45.07%, 34.57% and 20.36%, respectively. So, to develop the cnts reinforced al−cu alloy matrix composite with high mechanical properties, it is necessary to protect the cnts from transforming into al4c3 using proper tactics in the future, such as alloy composition optimization or pre coating cu on the surface of cnts. 5 conclusions (1) the cu content significantly affects the microstructure of the prepared composites, as. The wear width was reduced from 965 μm to 836 μm, so the wear resistance was significantly improved. the coefficient of friction (cof) and wear of the two materials are summarized in table 2. the 3d interconnected cnts cu composites exhibited better anti friction properties (cof ≈ 0.22) compared the cof for cu is 0.55.

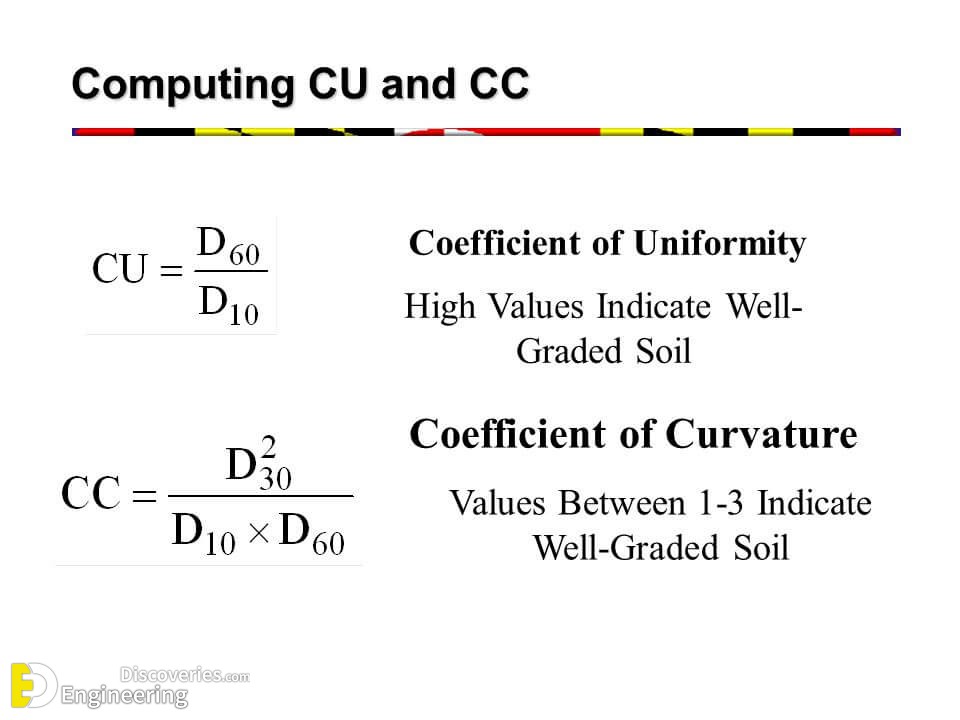

Coeficiente De Curvatura So, to develop the cnts reinforced al−cu alloy matrix composite with high mechanical properties, it is necessary to protect the cnts from transforming into al4c3 using proper tactics in the future, such as alloy composition optimization or pre coating cu on the surface of cnts. 5 conclusions (1) the cu content significantly affects the microstructure of the prepared composites, as. The wear width was reduced from 965 μm to 836 μm, so the wear resistance was significantly improved. the coefficient of friction (cof) and wear of the two materials are summarized in table 2. the 3d interconnected cnts cu composites exhibited better anti friction properties (cof ≈ 0.22) compared the cof for cu is 0.55. The sensitized cnts particles filtered off and finally were transferred to the cu coating bath containing 70 g l copper sulfate (cuso 4.5h 2 o) as a copper origin, 170 g l trisodium citrate dehydrate (na 3 c 6 h 9 o 9) as a complexing agent of the cu ions and 100 ml l formaldehyde (ch 2 o) as a reduction agent of the cu ions during coating [17, 24]. the solution ph was adjusted at 11.5 and the. Nonuniform dispersion and weak interfacial bonding between carbon nanotubes (cnts) and cu matrix are two critical issues for achieving high strength and good ductility of cnt cu composites. here, acid treated cnts precoated with ni coatings were used to enhance the dispersion uniformity of cnts and interfacial bonding between cnts and cu matrix in the cnt cu composites fabricated through spark.

Palabras Con Cu Ejemplos De Palabras Con Cu The sensitized cnts particles filtered off and finally were transferred to the cu coating bath containing 70 g l copper sulfate (cuso 4.5h 2 o) as a copper origin, 170 g l trisodium citrate dehydrate (na 3 c 6 h 9 o 9) as a complexing agent of the cu ions and 100 ml l formaldehyde (ch 2 o) as a reduction agent of the cu ions during coating [17, 24]. the solution ph was adjusted at 11.5 and the. Nonuniform dispersion and weak interfacial bonding between carbon nanotubes (cnts) and cu matrix are two critical issues for achieving high strength and good ductility of cnt cu composites. here, acid treated cnts precoated with ni coatings were used to enhance the dispersion uniformity of cnts and interfacial bonding between cnts and cu matrix in the cnt cu composites fabricated through spark.

Cum S г Vorbe шti юааcuюаб юааoюаб Fat в Prin Mesaje Simulare Conversa ыie Mesaj юааcuюаб

Comments are closed.