Chiller What Is It How Does It Work Types Uses

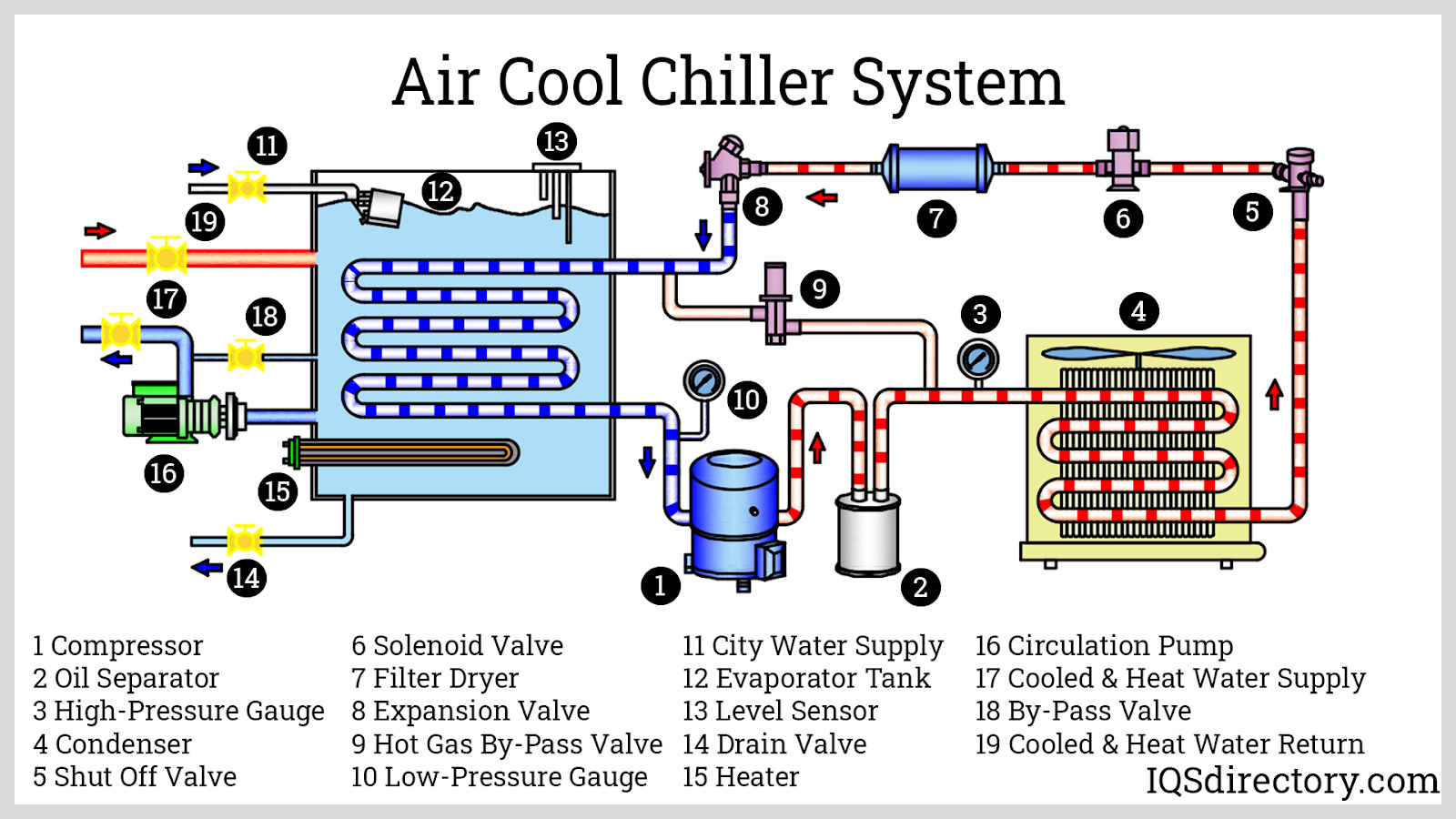

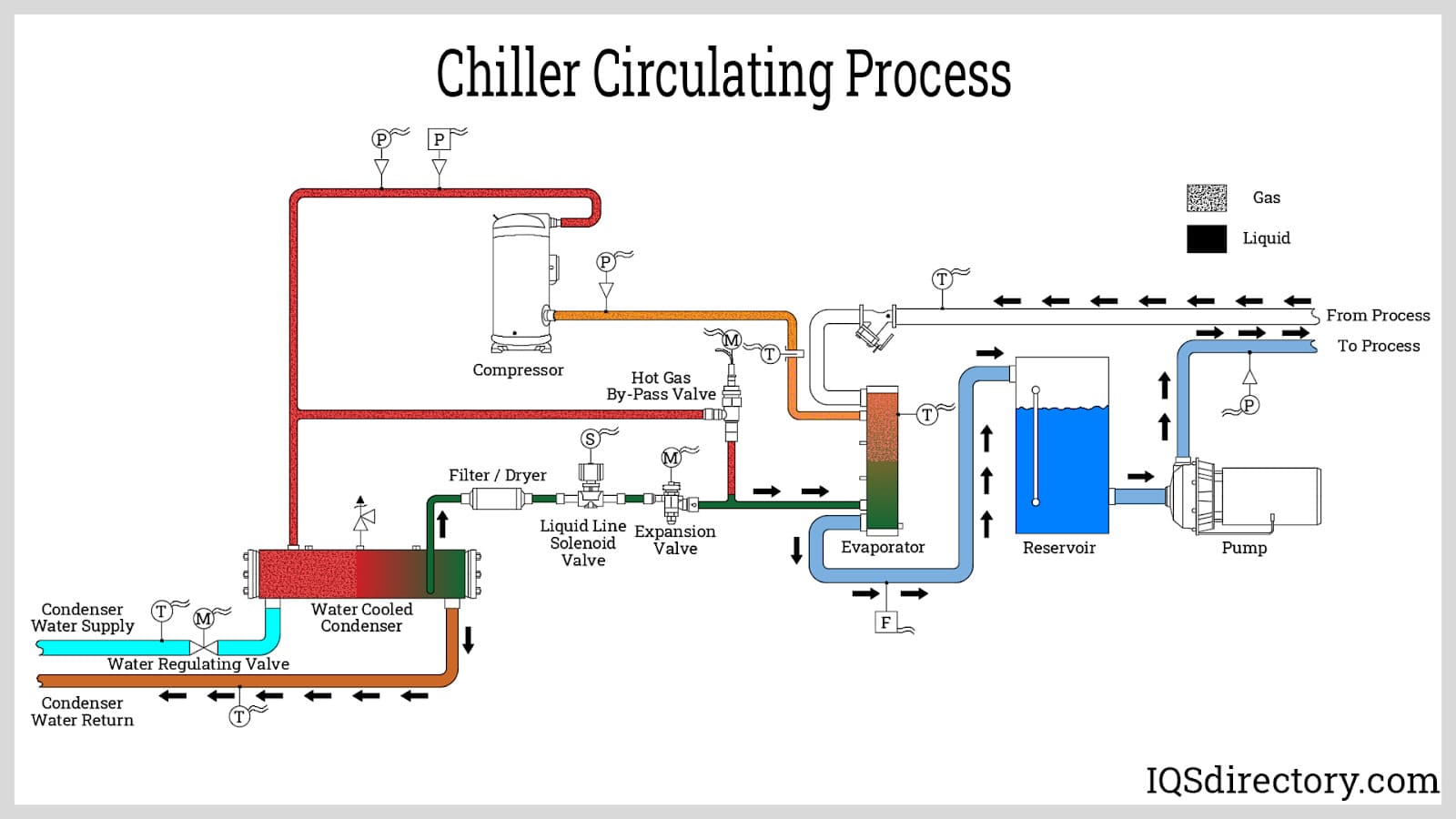

Chiller What Is It How Does It Work Types Uses A chiller is a cooling system designed to remove heat by circulating a refrigerant through various components where the heat is transferred and dissipated. key components of an industrial chiller include a compressor, condenser, expansion valve, and evaporator. these parts work together to circulate the refrigerant, effectively removing heat. Core uses, types & how they work. at its core, a chiller is a refrigeration system designed to remove heat through a vapor compression, absorption, or adsorption refrigeration cycle. the primary objective is to cool a fluid or dehumidify air in an industrial or commercial setting. simply put, a chiller is a machine that cools things down.

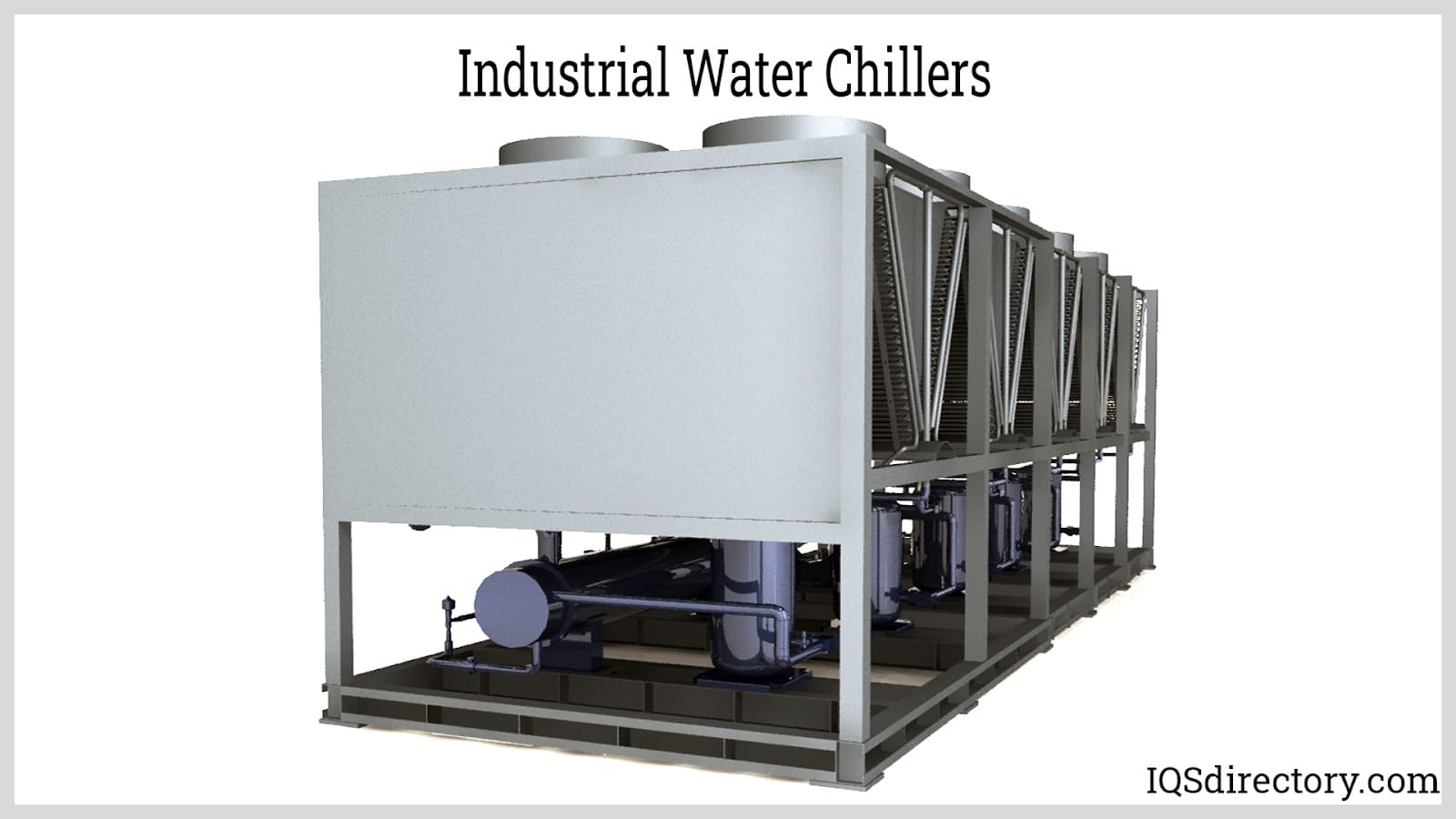

Water Chiller What Is It How Does It Work Types Uses Glycol chillers are special types that use propylene glycol, an anti freeze, in the system. they are widely used in food grade applications such as in the production of alcohol and for brewery chilling systems. how does a glycol chiller work? the mode of operation of glycol chillers is the same as a standard chiller. centrifugal chillers. A water chiller, or chilled water system, is a cooling system that uses water as a secondary refrigerant. they are used for large, complex heating, ventilating, air conditioning, and refrigeration (hvacr) applications. the main loops or circuits of a water chiller are the refrigeration loop and the chilled water loop. The different compressor technologies currently available – chiller types and application guide. centrifugal chillers. centrifugal chiller compressor. water cooled chillers. used in medium to large cooling loads. typically, available in 150 – 6,000 tr, 530 – 21,000 kw. water cooled cop of between 5.8 to 7.1. Chillers transfer heat away from a space that requires climate control much like a traditional split system or package unit does, but they use water (or a water solution) to do so instead of air. there are two types of chillers: water cooled and air cooled. they work similarly throughout most of the process until the refrigerant reaches the.

Chiller What Is It How Does It Work Types Uses The different compressor technologies currently available – chiller types and application guide. centrifugal chillers. centrifugal chiller compressor. water cooled chillers. used in medium to large cooling loads. typically, available in 150 – 6,000 tr, 530 – 21,000 kw. water cooled cop of between 5.8 to 7.1. Chillers transfer heat away from a space that requires climate control much like a traditional split system or package unit does, but they use water (or a water solution) to do so instead of air. there are two types of chillers: water cooled and air cooled. they work similarly throughout most of the process until the refrigerant reaches the. Chiller systems are essential for temperature control and cooling in several industries. choosing the right industrial chiller for process and space cooling can lower cooling costs, minimize downtime, and improve operational efficiency. this article will cover the different types of chillers for commercial and industrial applications and the pros and cons of each. the aim […]. A chiller uses a vapor compression mechanical refrigeration system that connects to the process water system through a device called an evaporator. refrigerant circulates through an evaporator, compressor, condenser and expansion device of a chiller. a thermodynamic process occurs in each of above components of a chiller.

Chiller What Is It How Does It Work Types Uses Vrogue Co Chiller systems are essential for temperature control and cooling in several industries. choosing the right industrial chiller for process and space cooling can lower cooling costs, minimize downtime, and improve operational efficiency. this article will cover the different types of chillers for commercial and industrial applications and the pros and cons of each. the aim […]. A chiller uses a vapor compression mechanical refrigeration system that connects to the process water system through a device called an evaporator. refrigerant circulates through an evaporator, compressor, condenser and expansion device of a chiller. a thermodynamic process occurs in each of above components of a chiller.

Comments are closed.