Cm13 Me Lab1 Bsme 3c Calibration Of Platform Scale Technological

Cm5 Me Lab1 Bsme 3c Test Of Solid Fuel Technological University Of Cm11 me lab1 bsme 3c calibration and use of pressure and temperature measuring instruments; cm14 me lab1 bsme 3c calibration of volume tank, water meter, orifice, venturi meter and weir; cm9 me lab1 bsme 3c cloud and pour point test; cm7 me lab1 bsme 3c flue gas analysis; activity automotive engineering; 06 heat exchanger efficiency. 1 the importance of calibration of platform scale. calibration quantifies and controls errors or uncertainties within measurement processes to an acceptable level. balance or scale calibration is essential to achieve accurate weighing results. ignoring this important service activity turns measuring into guesswork.

Free Stl File Calibration Platform For Imu And Ahrs рџ њгѓ 3d Print Design Cm13 me lab1 bsme 3c calibration of platform scale; cm11 me lab1 bsme 3c calibration and use of pressure and temperature measuring instruments; cm14 me lab1 bsme 3c calibration of volume tank, water meter, orifice, venturi meter and weir; cm9 me lab1 bsme 3c cloud and pour point test. Calibration is essential to ensure platform scales provide accurate measurements. the document outlines the calibration procedure which includes setting up the scale away from drafts, leveling it, performing span and corner load checks using specified weights, and recording results. accuracy is affected by factors such as load cell specifications, how loads are applied, and environmental. #ohtc#bulsu #profcharltonacademy the video report is about the calibration of the platform scale as reported by group 5 3rd year of bulsu me lab 1. Types of platform scales there are two main types of platform scales: mechanical and electronic. 1. mechanical platform scales use a system of levers and springs to measure the weight of an object. when an object is placed on the platform, it causes the platform to depress, which compresses the springs.

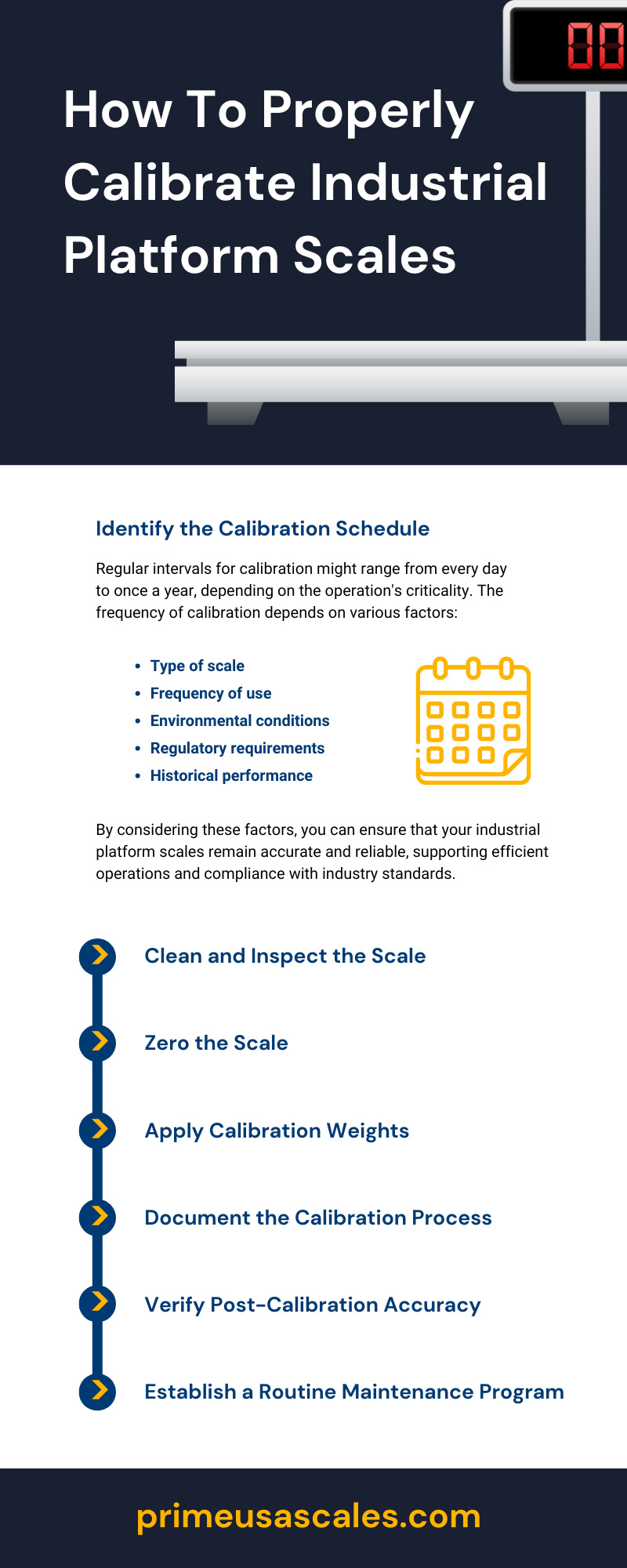

How To Properly Calibrate Industrial Platform Scales #ohtc#bulsu #profcharltonacademy the video report is about the calibration of the platform scale as reported by group 5 3rd year of bulsu me lab 1. Types of platform scales there are two main types of platform scales: mechanical and electronic. 1. mechanical platform scales use a system of levers and springs to measure the weight of an object. when an object is placed on the platform, it causes the platform to depress, which compresses the springs. Clean and inspect the scale. a clean and well maintained scale is fundamental for accurate calibration. start by cleaning the platform and removing any debris, dirt, or foreign objects that could affect the scale’s readings. use a soft brush or a lint free cloth to gently wipe away dust and particles. 1) platform scales are industrial weighing instruments used to weigh large or heavy objects. they consist of a lever system and standard weights that balance an unknown weight on the platform. 2) there are several types of platform scales including floor mounted, pit mounted, intrinsically safe, and bench mounted scales suited for different applications and environments. 3) platform scales.

Comments are closed.