Continuous Cooling Transformation Diagram Ppt

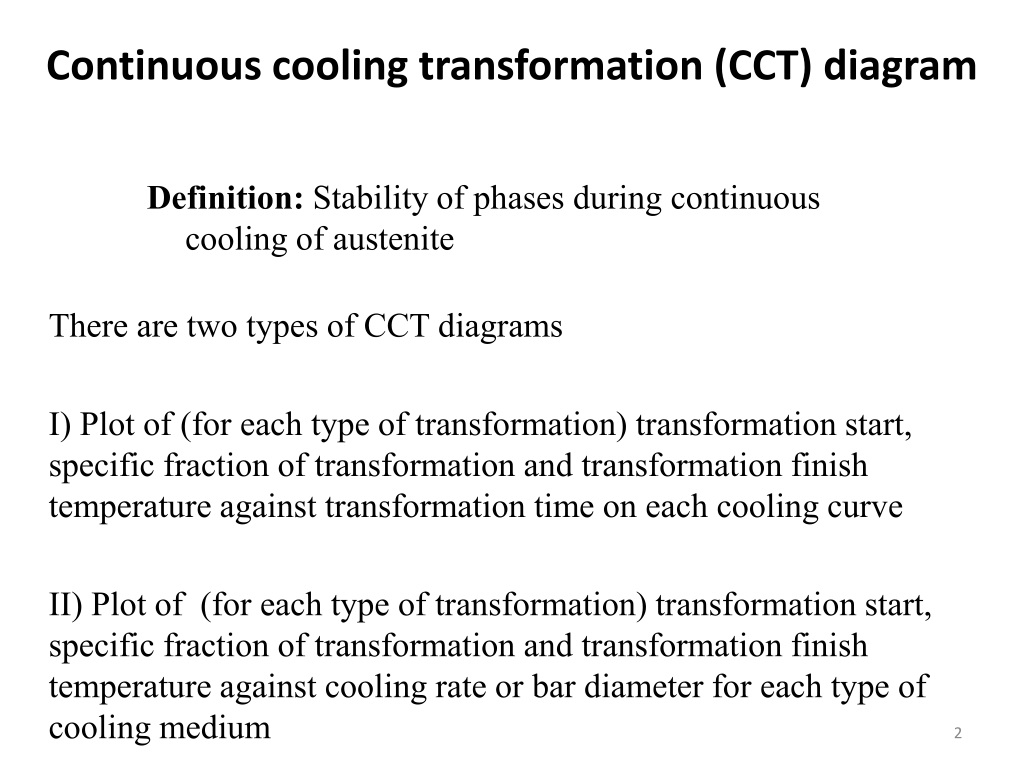

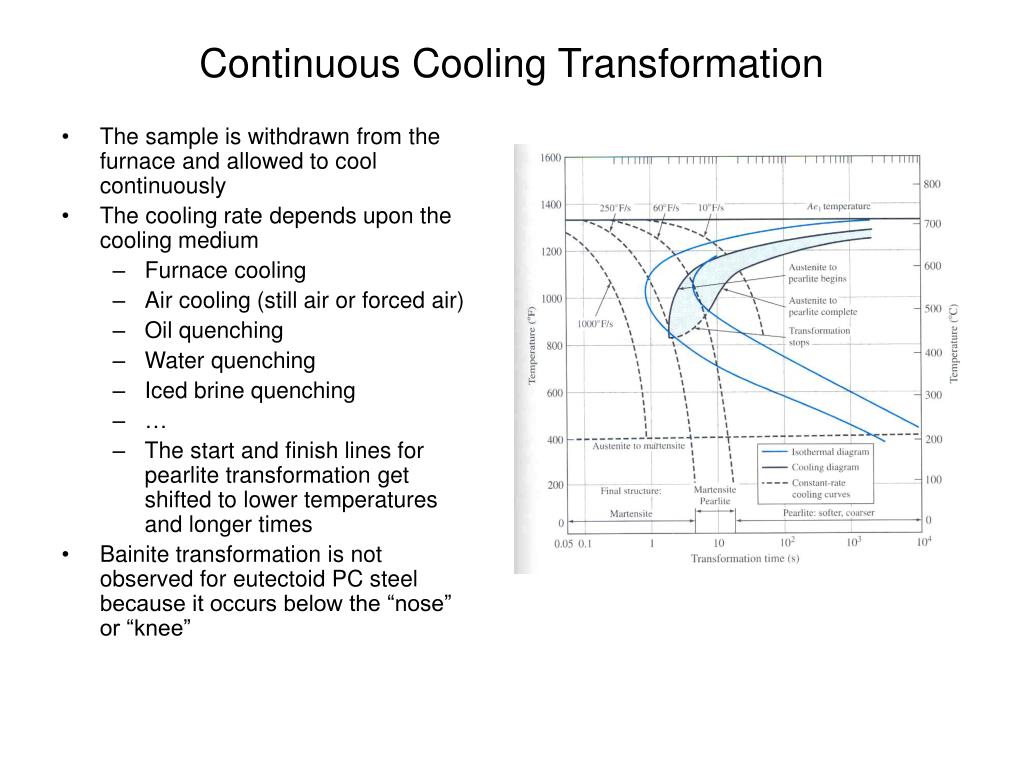

Ppt Continuous Cooling Transformation Cct Diagrams Powerpoint 4. it measure the extent of transformation as a function of time for a continuously decreasing temperature. usually materials are cooled continuously, thus continuous cooling transformation diagrams are appropriate. for continuous cooling, the time required for a reaction to begin and end is delayed, thus the isothermal curves are shifted to longer times and lower temperatures main difference. Definition: stability of phases during continuous cooling of austenite. there are two types of cct diagrams. i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve.

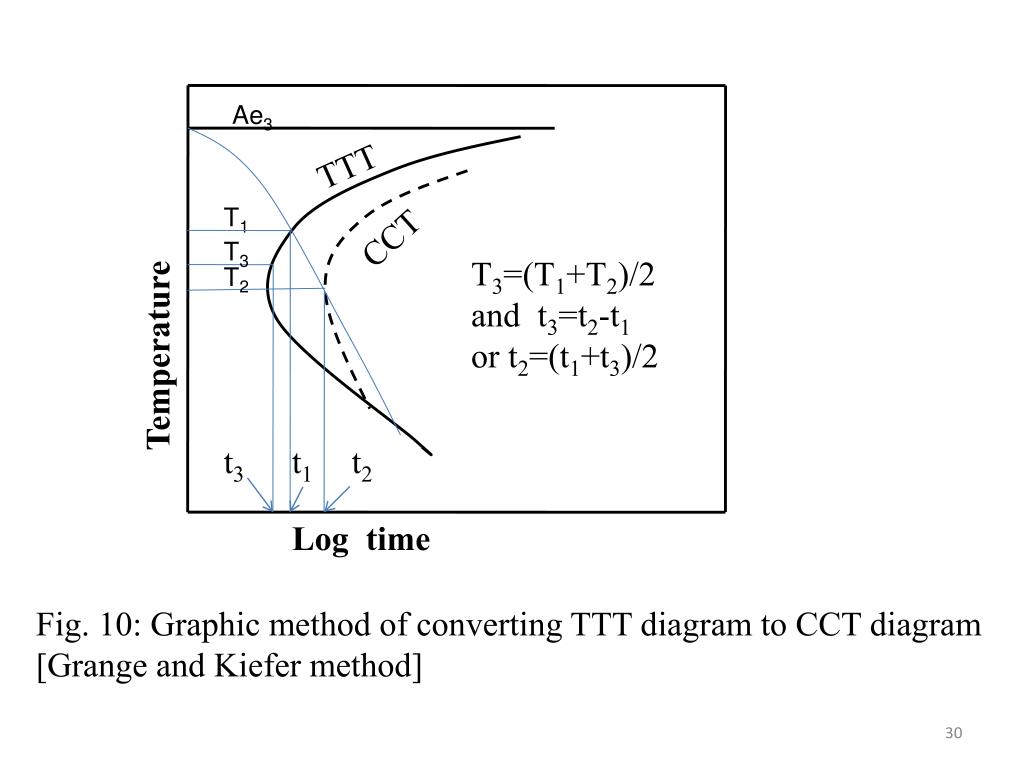

Ppt Chapter 10 Powerpoint Presentation Free Download Id 5893032 Title: continuous cooling transformation (cct) diagrams 1 continuous cooling transformation (cct) diagrams r. manna assistant professor centre of advanced study department of metallurgical engineering institute of technology, banaras hindu university varanasi 221 005, india rmanna.met at itbhu.ac.in tata steel traerf. Cct diagram depends on composition of steel, nature of cooling, austenite grain size, extent of austenite homogenising, as well as austenitising temperature and time. 2. similar to ttt diagrams there are different regions for different transformation (i.e. cementite ferrite, pearlite, bainite and martensite). Continuous cooling transformation (cct) diagram definition: stability of phases during continuous cooling of austenite there are two types of cct diagrams i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve ii) plot of (for each type of transformation. Microsoft powerpoint metal slides. continuous cooling transformation diagram for a type 4340 alloy steel with superimposed cooling curves illustrating the manner in which transformation behavior during continuous cooling governs the final micro structure. (adapted from mechanical engineers’ handbook, 2nd ed., m. kutz, ed.

Ppt Continuous Cooling Transformation Cct Diagrams Powerpoint Continuous cooling transformation (cct) diagram definition: stability of phases during continuous cooling of austenite there are two types of cct diagrams i) plot of (for each type of transformation) transformation start, specific fraction of transformation and transformation finish temperature against transformation time on each cooling curve ii) plot of (for each type of transformation. Microsoft powerpoint metal slides. continuous cooling transformation diagram for a type 4340 alloy steel with superimposed cooling curves illustrating the manner in which transformation behavior during continuous cooling governs the final micro structure. (adapted from mechanical engineers’ handbook, 2nd ed., m. kutz, ed. 4. it measure the extent of transformation as a function of time for a continuously decreasing temperature. usually materials are cooled continuously, thus continuous cooling transformation diagrams are appropriate. for continuous cooling, the time required for a reaction to begin and end is delayed, thus the isothermal curves are shifted to longer times and lower temperatures main difference. Ttt diagrams apply to isothermal heat treatments where temperature is held constant, while cct diagrams apply to continuous cooling processes. the document outlines various microstructures including pearlite, bainite, martensite, and spheroidite and how they form on these diagrams. it also discusses how alloying elements can shift the.

Ppt Continuous Cooling Transforming Diagram Pdfslide Net 4. it measure the extent of transformation as a function of time for a continuously decreasing temperature. usually materials are cooled continuously, thus continuous cooling transformation diagrams are appropriate. for continuous cooling, the time required for a reaction to begin and end is delayed, thus the isothermal curves are shifted to longer times and lower temperatures main difference. Ttt diagrams apply to isothermal heat treatments where temperature is held constant, while cct diagrams apply to continuous cooling processes. the document outlines various microstructures including pearlite, bainite, martensite, and spheroidite and how they form on these diagrams. it also discusses how alloying elements can shift the.

Ppt Chapter 10 Phase Transformations Powerpoint Presentation Free

Comments are closed.