Cooling Tower Overflowing Follow Up Work Order I Shouldve Check This

юааcoolingюаб юааtowerюаб юааoverflowingюаб юааfollow Upюаб юааworkюаб юааorderюаб юааi Shouldтащveю Going back to figure out cooling tower 1 water overflowing during shutdown #hvac #coolingtower #chiller. Excessive noise or vibration from a cooling tower can indicate underlying problems that need attention. here are some troubleshooting steps: check the alignment of the motor, fan, and drive shaft. misalignment can cause excessive vibration and noise. make necessary adjustments to ensure proper alignment. lubricate the motor bearings regularly.

Cooling Tower Checklist A step by step cooling tower maintenance checklist; regular maintenance of cooling towers is vital for their efficient operation and longevity. here is the step by step checklist, that can help keep your cooling tower in optimal condition. so check out the below steps. step 1: inspect the tower exterior. Cooling tower issues and troubleshooting approaches. the water temperature rises unexpectedly. the recommended air flow may be low. adjusting the blade level may correct this. the water flow may be above the recommended level. take applicable steps to correct the rate of flow. the sprinkler output may be impeded resulting in poor distribution. Cleaning and lubricating components will help you ensure that your cooling tower’s mechanical system is free from dirt, debris, and corrosion. some steps to follow include: cleaning the fill media, drift eliminator, basin, and other components. lubricating the motor bearings, pump, and other moving parts. This cooling tower repair might include a filter system or even chemical corrosion inhibitors. 2 clogged water system. a clogged water system can stop your cooling tower in its tracks. cooling towers run day after day, and particles slowly build up in the system. this can be any particle that is in the water and gets trapped inside the tower.

Industrial Cooling Tower Araner Cleaning and lubricating components will help you ensure that your cooling tower’s mechanical system is free from dirt, debris, and corrosion. some steps to follow include: cleaning the fill media, drift eliminator, basin, and other components. lubricating the motor bearings, pump, and other moving parts. This cooling tower repair might include a filter system or even chemical corrosion inhibitors. 2 clogged water system. a clogged water system can stop your cooling tower in its tracks. cooling towers run day after day, and particles slowly build up in the system. this can be any particle that is in the water and gets trapped inside the tower. Biological contamination. scaling. fouling. there are four significant kinds of treatment of water issues that component cooling towers should monitor. these are corrosion, fouling, biological contamination, and scaling. these issues decrease the cooling pinnacle’s capacity to be energy productive as planned. Mccrometer flow meters for cooling tower water management. not all flow meters are created equal, and not every meter is right for every application. variables include the fluid as well as the usage, and both cooling towers and hvac systems are required to measure flow to 0.5% accuracy.

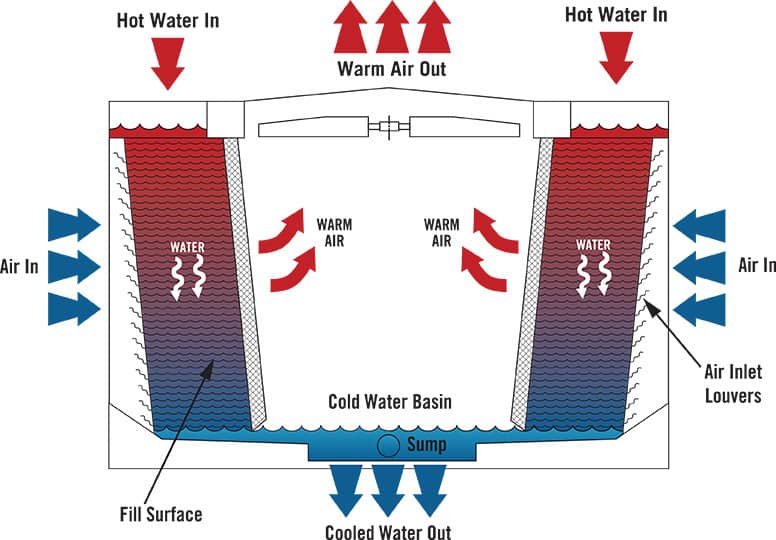

Cooling Tower Fan Working Principle At Eddie Stewart Blog Biological contamination. scaling. fouling. there are four significant kinds of treatment of water issues that component cooling towers should monitor. these are corrosion, fouling, biological contamination, and scaling. these issues decrease the cooling pinnacle’s capacity to be energy productive as planned. Mccrometer flow meters for cooling tower water management. not all flow meters are created equal, and not every meter is right for every application. variables include the fluid as well as the usage, and both cooling towers and hvac systems are required to measure flow to 0.5% accuracy.

Cooling Tower Inspection Guide Ppt

Comments are closed.