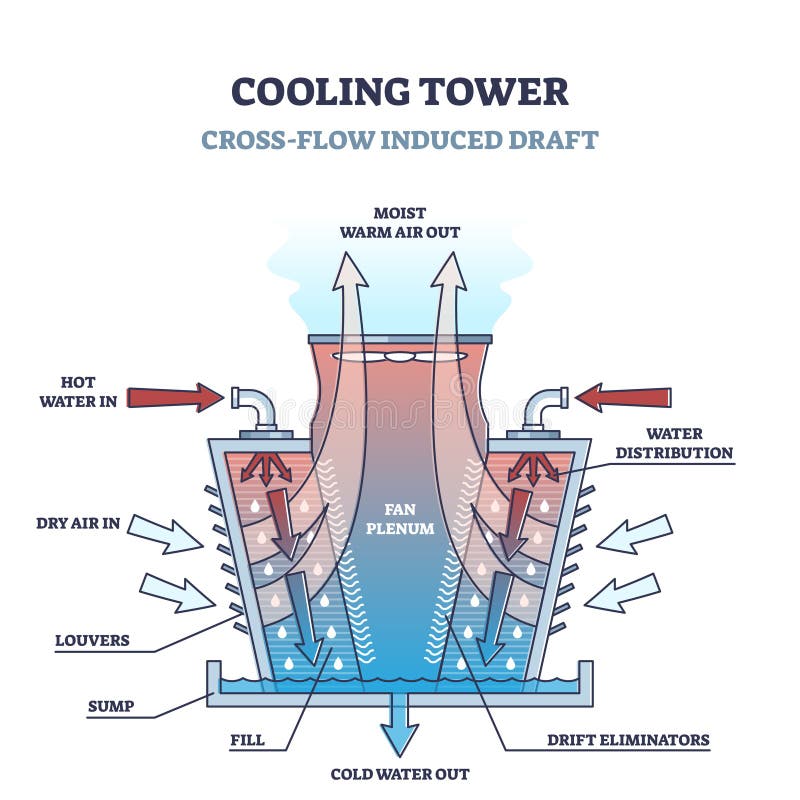

Cooling Tower Single Line Diagram

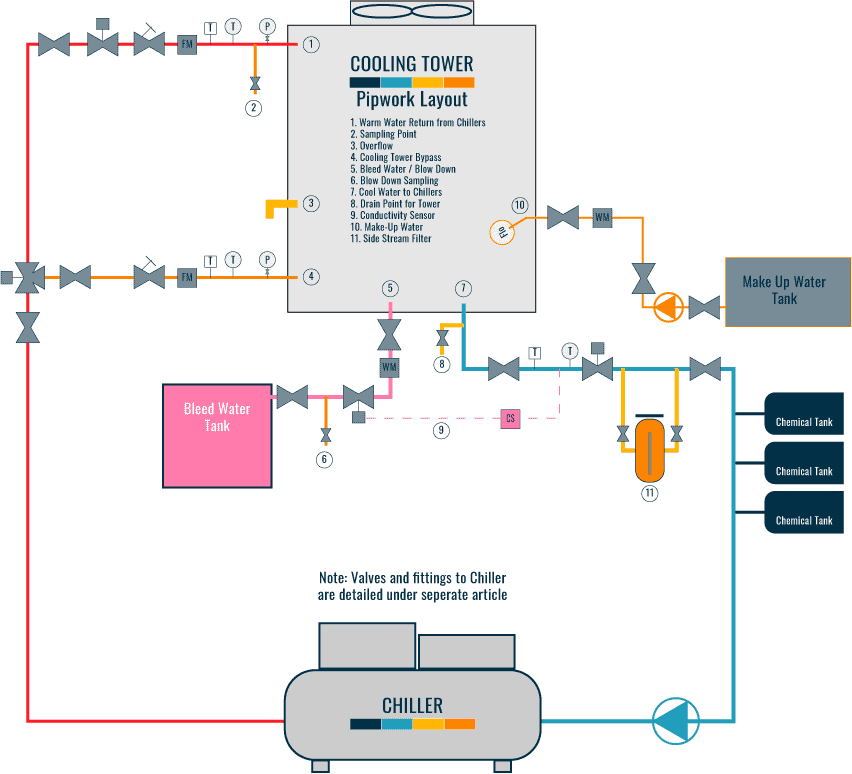

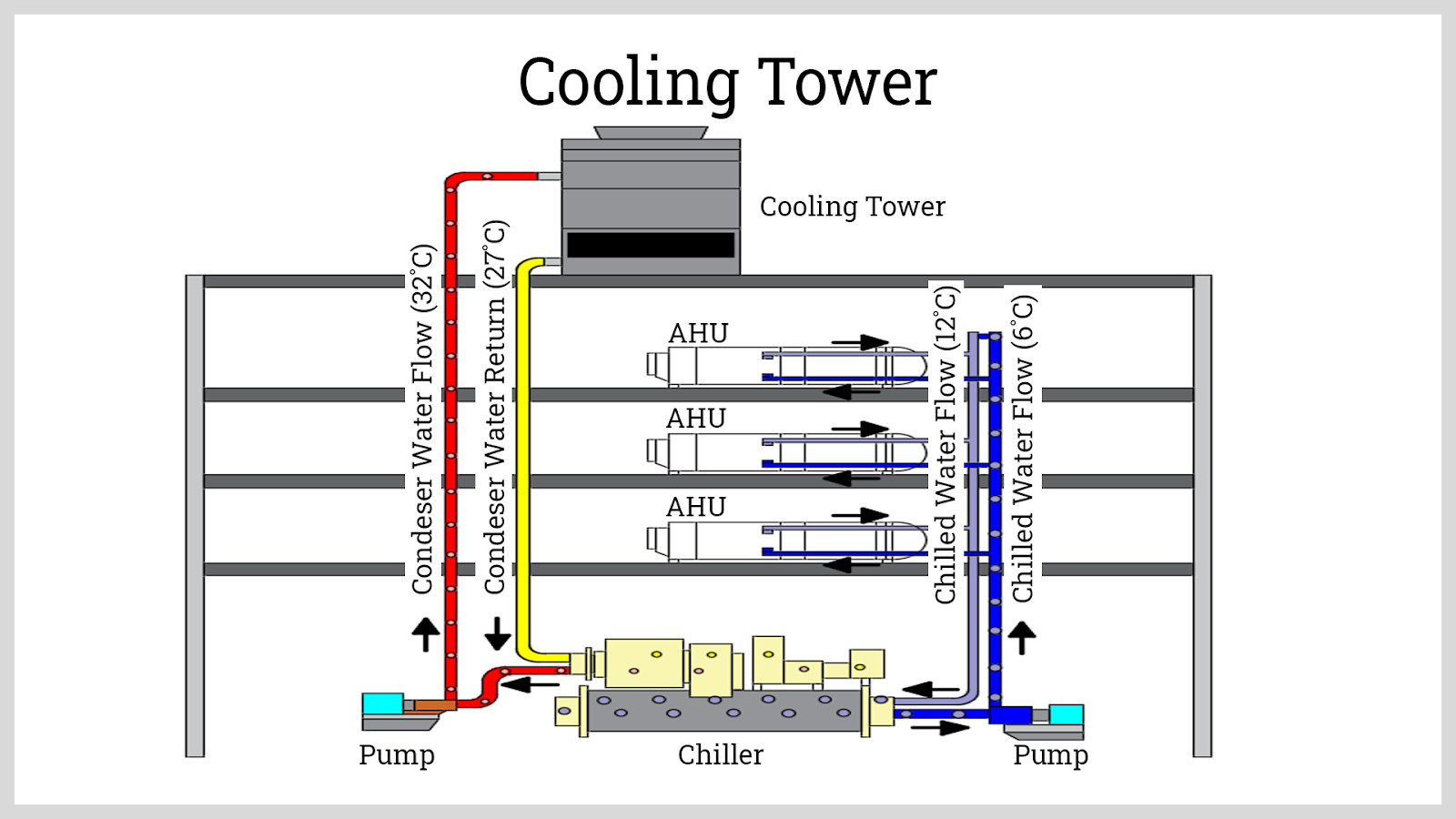

Cooling Tower Piping Layout And Diagrams Constructandcommission Cooling tower | piping layout and diagrams. to allow the cooling towers to operate correctly, in line with the design and efficiently, various systems will need to be connected to allow them to work. depending upon how the towers are installed will mean different configurations would be required. the pipework that is commonly connected to the. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower.

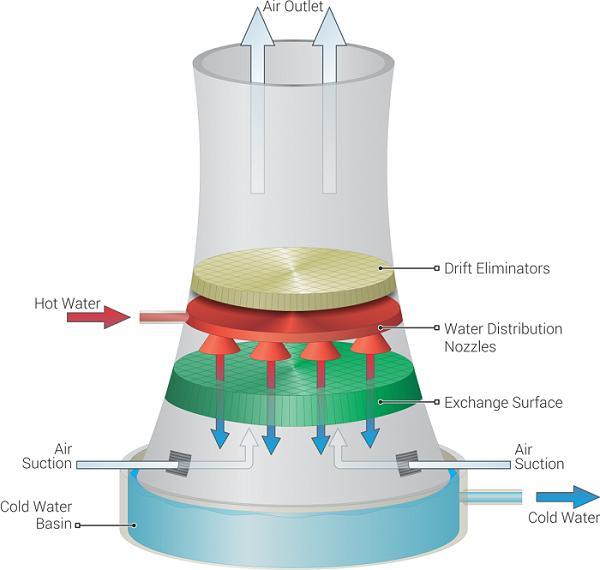

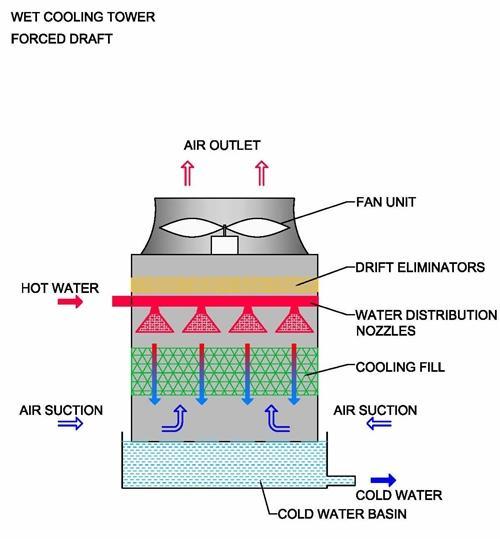

Cooling Tower Diagram A Go To Guide To Learn About Their Function The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. Towers and provides important aspects of cooling tower types, sizing, selection and performance issues. let’s first define few important terms for understanding this course. a detailed glossary is provided at the end of the course. cooling tower terms and definitions . some useful terms, commonly used in the cooling tower industry: 1. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

Cooling Towers Components Working Principles And Lifespan A The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the. Cooling tower fill media what is cooling tower fill media? fill media is by far one of the most important cooling tower components. it could be considered the middle man of the entire process. many of today's cooling towers use efficient plastic film fills or fill media that maximize the surface area for evaporative cooling processes. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

Cooling Tower Diagram A Go To Guide To Learn About Their Function Cooling tower fill media what is cooling tower fill media? fill media is by far one of the most important cooling tower components. it could be considered the middle man of the entire process. many of today's cooling towers use efficient plastic film fills or fill media that maximize the surface area for evaporative cooling processes. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging.

Cross Flow Cooling Tower Type Structure And Work Principle Outline

Comments are closed.