Cooling Tower Water Use Optimization Epic Epri Etcc

Et17sce1020 Cooling Tower Water Use Optimization Epic Epri Etcc The m&v results confirmed substantial water savings and chemical reduction at both host sites: 30% for the hotel site, with typical practices (coc was increased from 2.3 to 5.9) and 15% for the pharmaceutical site with best practices (coc was increased from 3.6 to 7.8). chemical usage cost reductions ranged from greater than 30% at the hotel. Approximately 98% of u.s. cooling towers use only chemical water treatment provided by a well established market channel of chemical companies and service providers. the use of physical water treatment (pwt) technologies for water cooled cooling towers is growing in the u.s., and has been more widely used, primarily in the european union, where.

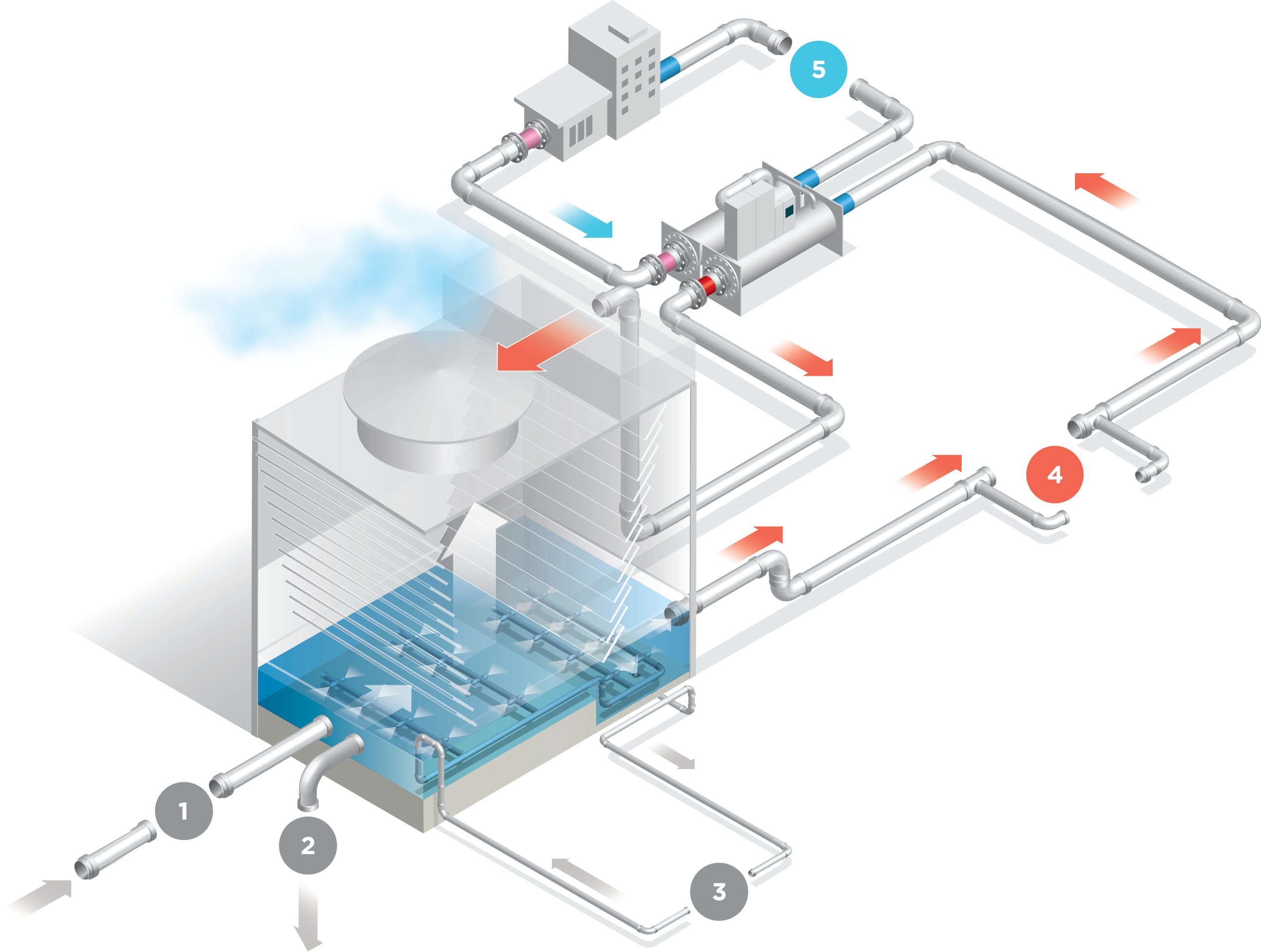

Et17sce1020 Cooling Tower Water Use Optimization Epic Epri Etcc Other major uses of water in the power plant include flue gas scrubbing, ash sluicing, boiler make up, gas turbine inlet cooling, dust control, and “hotel housekeeping” activities. power plants currently account for about 3% of the freshwater consumed in the u.s., in contrast with agriculture, which consumes about 40%. Water is commonly used to manage excess heat in many processing plants. specifically, evaporative cooling towers dissipate heat from industrial processes through a combination of heat and mass transfer. an evaporative cooling tower can operate over a wide range of recirculating water rates, air velocity rates, heat loads, and ambient weather. The blue plan it® cooling tower dashboard cooling towers use significant amounts of water. the thermal efficiency and longevity of the cooling tower and its equipment depend on the quality of the makeup water and the proper management of recirculated water. carollo’s blue plan‐it® (bpi) decision support system offers an advanced approach. Ivg ct technology on cooling towers in relation to the reduction of water consumption, energy and elimination of chemical use • study carried out from july 2016 to april 2020 in california on two sites equipped with cooling towers: a large hotel and pharmaceutical factory where water treatment was representative of standard practices:.

Cooling Tower Water Treatment Veolia Water Technologies The blue plan it® cooling tower dashboard cooling towers use significant amounts of water. the thermal efficiency and longevity of the cooling tower and its equipment depend on the quality of the makeup water and the proper management of recirculated water. carollo’s blue plan‐it® (bpi) decision support system offers an advanced approach. Ivg ct technology on cooling towers in relation to the reduction of water consumption, energy and elimination of chemical use • study carried out from july 2016 to april 2020 in california on two sites equipped with cooling towers: a large hotel and pharmaceutical factory where water treatment was representative of standard practices:. More recently, dalibard et al. used trnsys, a simulation program in which the cooling tower model used is the braun effectiveness model, to model a chilled water plant and optimize its performance through the sequencing of the operation of cooling towers in a plant and introducing an outdoor air temperature dependent cooling water setpoint [35]. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

Water Treatment Process For Cooling Towers At Truman Taylor Blog More recently, dalibard et al. used trnsys, a simulation program in which the cooling tower model used is the braun effectiveness model, to model a chilled water plant and optimize its performance through the sequencing of the operation of cooling towers in a plant and introducing an outdoor air temperature dependent cooling water setpoint [35]. Sequence of operation. when the operating fan(s) are operating at 50 percent speed, an additional fan shall be enabled and controlled at the same speed as the operating fans until all active cooling tower cell fans are enabled. when operating fans are running at minimum speed and the tower supply water temperature is five (5) degrees below the.

Leveraging Advanced Water Filtration To Maximize Cooling Tower Performance

Comments are closed.