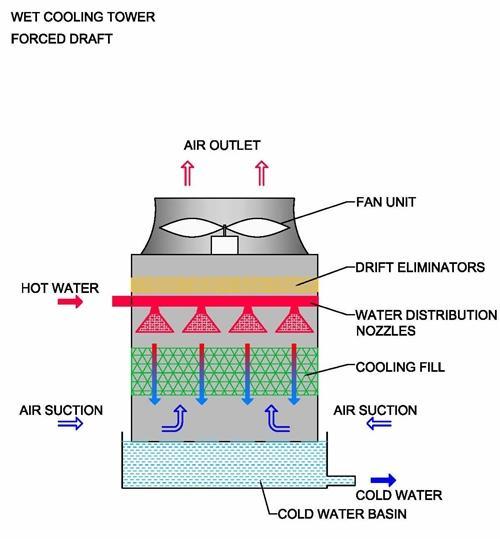

Cooling Towers Cooling Tower Diagram

Cooling Towers Explained How Does A Cooling Tower Work The water is flashed to air as it passes throughout the cooling tower. the air has been pulled using a motor driven electrical "cooling tower fan". when the air and water come into the contact, a little amount of water dissipates, producing a cooling operation. and again the cold water is pumped back to the machine that incorporates heat or the. Basically, the cooling tower is a kind of heat exchanger that removes heat from the water, rejects waste heat to the atmosphere with the help of cooling of water stream at lower temperatures. cooling towers are commonly seen in oil refineries, petrochemical, and chemical plants, thermal power stations and nuclear power stations, etc.

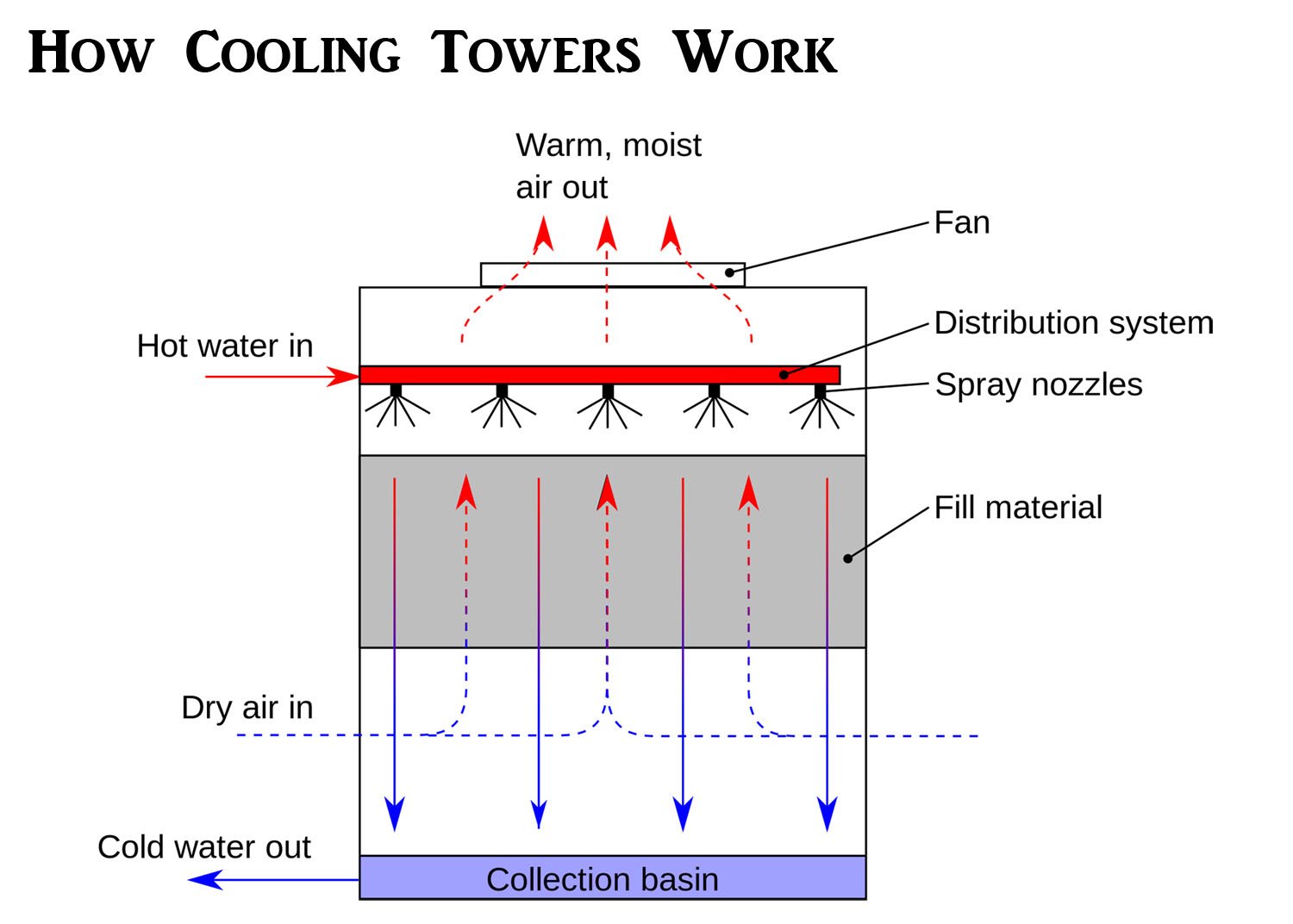

Cooling Tower Diagram A Go To Guide To Learn About Their Function Crossflow cooling towers flow diagram in crossflow cooling tower systems the water vertically flows through the fill media while the air horizontally flows across the falling water. that's why they call it "crossflow" because the air and water cross paths or flows. because of the crossing of flows, the air doesn't need to. A cooling tower flow diagram helps visualise the complex system of the tower and its components. the diagram illustrates the flow of water and air through the tower, as well as the different stages of the cooling process. the cooling tower flow diagram typically begins with the entry of hot water from the industrial process into the tower. Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser.

How Cooling Towers Work W Diagram Pictures Principles 2018 Cooling tower air flowing past fill packaging. combining the spray of water, the thin film of water on the fill packaging and the flow of cool air you get a great amount of heat transfer. flow of air and condenser water. just to recap. warm condenser water enters the tower and is sprayed over the fill packaging. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. The cold air drawn in through the bottom hits the exchange surface, cooling down the hot water which then drops into the basin at the bottom of the cooling tower. this water is then funnelled back into the industrial system industrial process from where it came and the whole cycle begins again. it is estimated that around 2% of the water which. A typical evaporative, forced draft open loop cooling tower rejecting heat from the condenser water loop of an industrial chiller unit natural draft wet cooling hyperboloid towers at didcot power station (uk) forced draft wet cooling towers (height: 34 meters) and natural draft wet cooling tower (height: 122 meters) in westphalia, germany natural draft wet cooling tower in dresden (germany).

Comments are closed.