Crossflow Vs Counterflow Cooling Towers

How To Pick A Cooling Tower Crossflow Versus Counterflow However, a disadvantage of a crossflow cooling tower is the footprint. due to the method by which air interacts with the process water, the footprint of the cooling tower is larger. 2. counterflow cooling towers. on the flipside, in counterflow cooling towers air is drawn upwards vertically to meet the flow of falling hot water in the fill. At cooling capacities up to about 750 tons (3295kw), a counterflow cooling tower with its vertically stacked components may require less plan area than a crossflow cooling tower. beyond the 750 ton mark, because crossflow tower modules are stacked vertically at higher tonnages, a counterflow tower offers little to no advantage in footprint versus a crossflow tower and can sometimes take up.

Which Cooling Tower Is Best Crossflow Or Counterflow Mep Academy Tower. up to about 750 tons (3295 kw), a counterflow cooling tower requires less plan area than a crossflow cooling tower, which makes counterflow cooling towers advantageous in densely populated metro areas with limited space. at about the 750 ton mark, counterflow towers offer little to no advantage in footprint relative to a crossflow tower. The most important point about crossflow cooling towers when comparing crossflow vs counterflow cooling towers is that they perform better in hot climates, and wherein low noise levels are required. on the other hand, while comparing crossflow vs counterflow cooling towers, counterflow cooling towers appear to have more acceptable configurations for applications where there is space limitation. Summary. babcock & wilcox has extensive experience in engineering, designing, and installing best in class spig ® technology in both counterflow and crossflow cooling towers. many customers prefer counterflow cooling towers based on efficiency, maintenance and emissions project goals. we leverage our more than 85 years’ experience from a. Increase fan hp (more cfm) #3 in image below. cooling tower capacity vs footprint, height and hp (cfm) crossflow cooling towers are better at turndown than counterflow because of the inherent features of their water distribution methods. cooling towers are rated based on standard conditions of 95ºf (35.0ºc) entering water temperature to an.

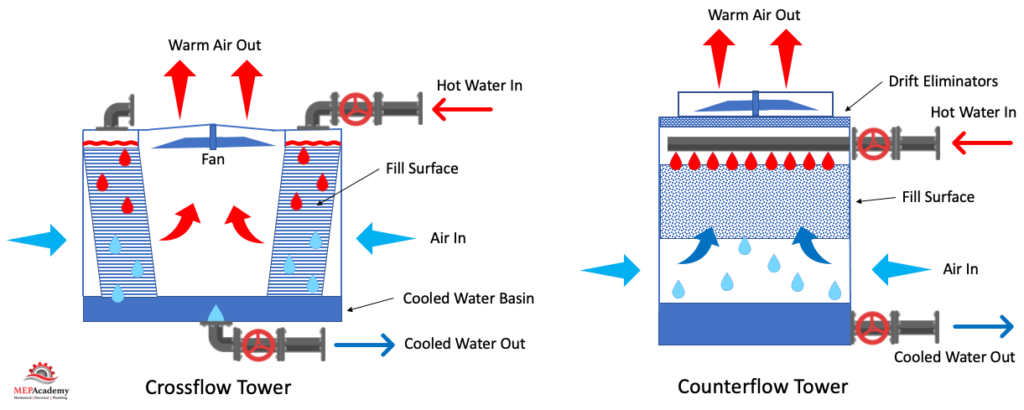

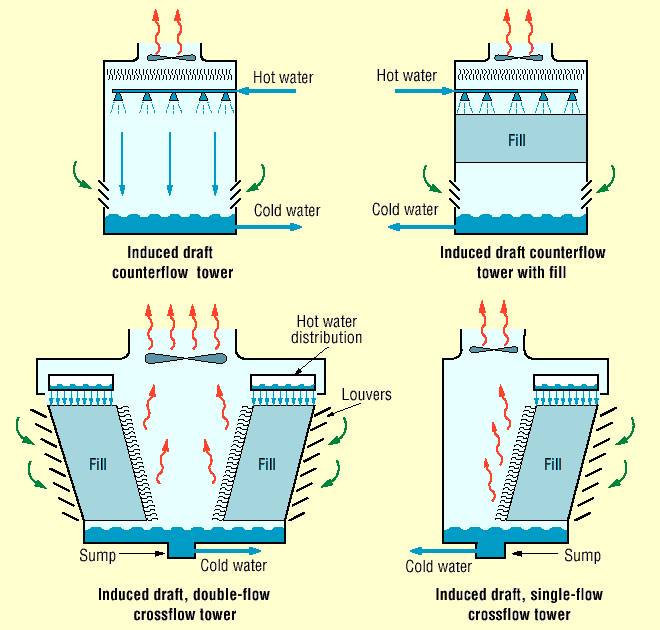

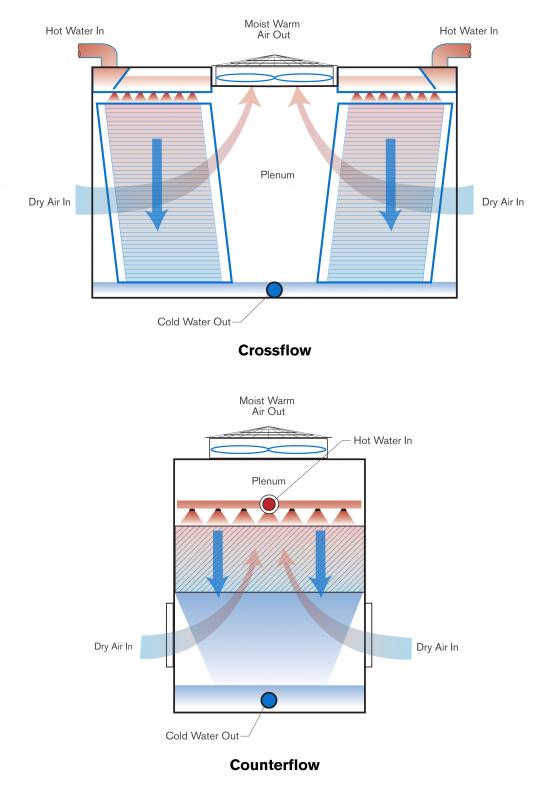

Counter Flow And Cross Flow Cooling Towers Tianjin Latino Summary. babcock & wilcox has extensive experience in engineering, designing, and installing best in class spig ® technology in both counterflow and crossflow cooling towers. many customers prefer counterflow cooling towers based on efficiency, maintenance and emissions project goals. we leverage our more than 85 years’ experience from a. Increase fan hp (more cfm) #3 in image below. cooling tower capacity vs footprint, height and hp (cfm) crossflow cooling towers are better at turndown than counterflow because of the inherent features of their water distribution methods. cooling towers are rated based on standard conditions of 95ºf (35.0ºc) entering water temperature to an. Cooling towers for hvac systems come in either crossflow or counterflow configurations. this is defined by the way the water meets the heat transfer surface, more commonly known as the “fill” surface. crossflow cooling towers distribute the hot water perpendicularly to the air flow. water flows from the top of the cooling tower through the. Spx cooling tech demonstrates the differences and advantages of each design. spx cooling tech, llc is a leading global manufacturer of cooling towers, evaporative fluid coolers, evaporative condensers and air cooled heat exchangers. for a century, we have provided exceptional quality equipment and service to the hvac, process cooling.

How Cooling Towers Work Counterflow Vs Crossflow Youtube Cooling towers for hvac systems come in either crossflow or counterflow configurations. this is defined by the way the water meets the heat transfer surface, more commonly known as the “fill” surface. crossflow cooling towers distribute the hot water perpendicularly to the air flow. water flows from the top of the cooling tower through the. Spx cooling tech demonstrates the differences and advantages of each design. spx cooling tech, llc is a leading global manufacturer of cooling towers, evaporative fluid coolers, evaporative condensers and air cooled heat exchangers. for a century, we have provided exceptional quality equipment and service to the hvac, process cooling.

Crossflow Or Counterflow Choosing A Cooling Tower For Your Application

Comments are closed.