Cryogenic Air Separation Plant Design

Cryogenic Process Of Air Separation вђ Ispatguru Cryogenic air separation is a well established technology. however, due to its associated energy intensity and hazardousness, new studies are always emerging on this topic. nevertheless, economic feasibility studies of cryogenic separation plants are still scarce. studies of this type are essential because installing an air separation unit can also be considered at the design stage of other. This publication serves the interest of those associated or concerned with air separation plant operations and applies to safety in the design, location, construction, installation, operation, and maintenance of cryogenic air separation plants. emphasis is placed on equipment and operational and maintenance features that are specific.

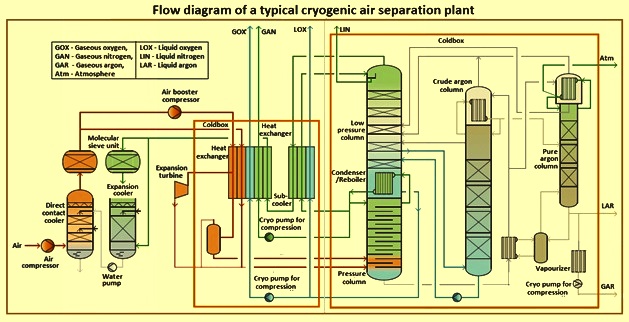

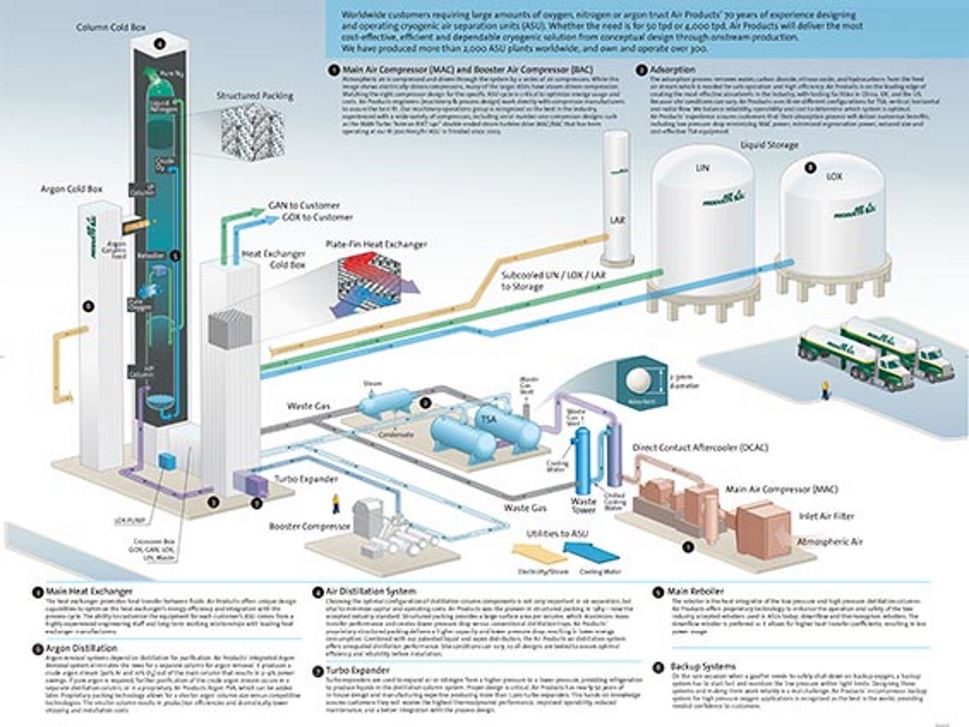

Cryogenic Air Separation Plant Air Products Cryogenic air separation is a process used to separate air into its constituent gases – primarily oxygen, nitrogen, and argon. the term ‘cryogenic’ refers to very low temperatures required for the process, typically below 150°c. at these extreme temperatures, air components liquefy, making it easier to separate them based on their. The design of a cryogenic air separation plant depends on the scale of operations and the nature of the products required from it. while basic principles are always the same, process cycles and flow for each plant can vary significantly based on the requirement. Successful delivery of over 4,000 air separation plants in over 90 countries. hands on insights from the operation of more than 550 asus. currently more than 356 patents protect linde air separation technologies. 19% tco savings in the operation of our plants over the last 10 years. 15% drop in average asu power consumption over the last 10 years. Air products currently owns and operates over 300 air separation plants in over 40 countries worldwide, in all types of applications. in addition to our own plants, we have sold, designed and built over 1000 air separation plants globally. our cryogenic offering spans from plants with a capability of 50 tons per day to single train facilities.

Cryogenic Air Separation Plant Design Successful delivery of over 4,000 air separation plants in over 90 countries. hands on insights from the operation of more than 550 asus. currently more than 356 patents protect linde air separation technologies. 19% tco savings in the operation of our plants over the last 10 years. 15% drop in average asu power consumption over the last 10 years. Air products currently owns and operates over 300 air separation plants in over 40 countries worldwide, in all types of applications. in addition to our own plants, we have sold, designed and built over 1000 air separation plants globally. our cryogenic offering spans from plants with a capability of 50 tons per day to single train facilities. Figure 2 cryogenic air separation plant with heat exchanger and distillation column towers (source air products) a) ariane 5 (25 t liquid hydrogen, 130 t liquid oxygen) b) space shuttle (100 t liquid hydrogen, 600 t liquid oxygen) figure 3 rockets using cryogenic liquid propellants. Here, the liquefied natural gas is converted back to gas and supplied to the distribution and transmission infrastructures. cryogenic lng has a high potential for cold energy recovery throughout the regasification process. this research examines a novel air separation unit (asu) design that is combined with lng's direct expansion cycle (dec).

Comments are closed.