Cryogenic Distillation Of Air Chemical Engineering World

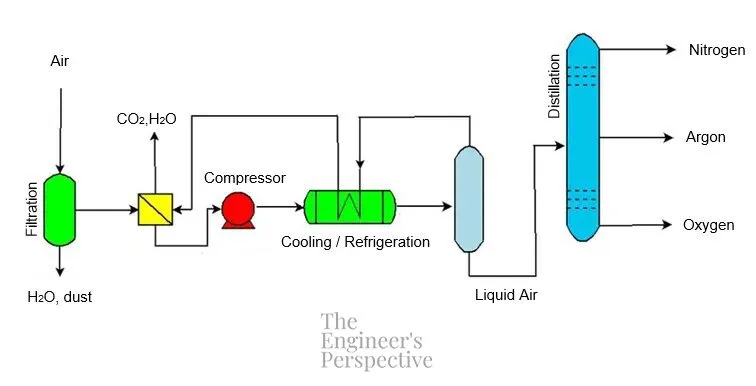

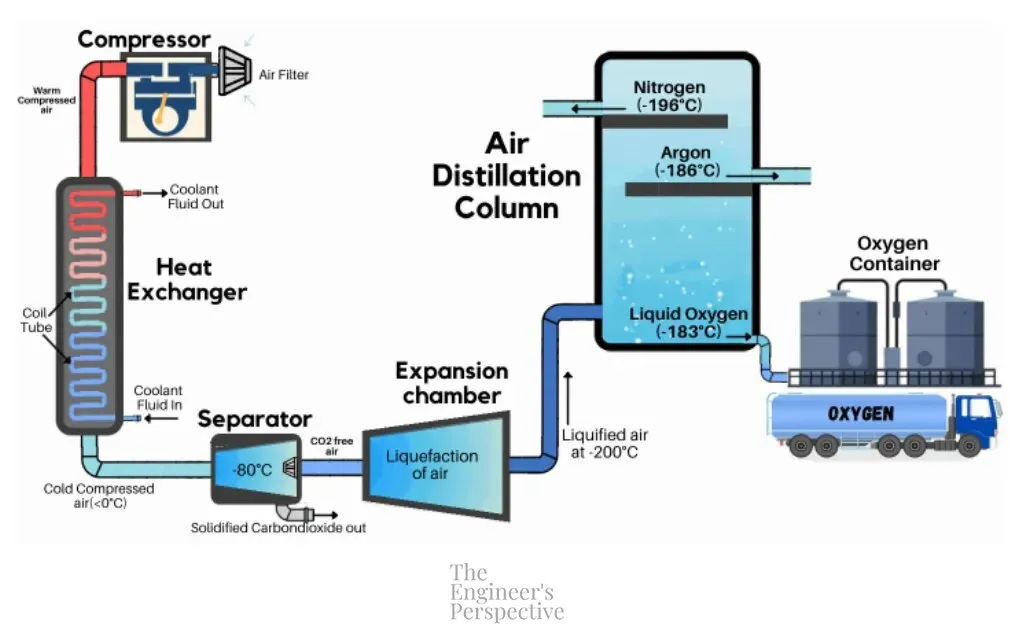

Cryogenic Distillation Of Air Chemical Engineering World Cryogenic distillation is the process in which nitrogen and oxygen are separated from air. in some cases argon is also separated. the word ‘cryogenic’ is related to low temperatures and the word ‘distillation’ is related to separation of constituents from a mixture by utilizing the property of boiling point of the constituents. Through a process called liquefaction, air condenses and becomes liquid at cryogenic temperature. distillation of air. by slowly warming up the liquid air, distillation separates air into its different component gases. nitrogen is separated first (boiling point 196°c), then argon (boiling point 186°c), and oxygen last (boiling point 183°c).

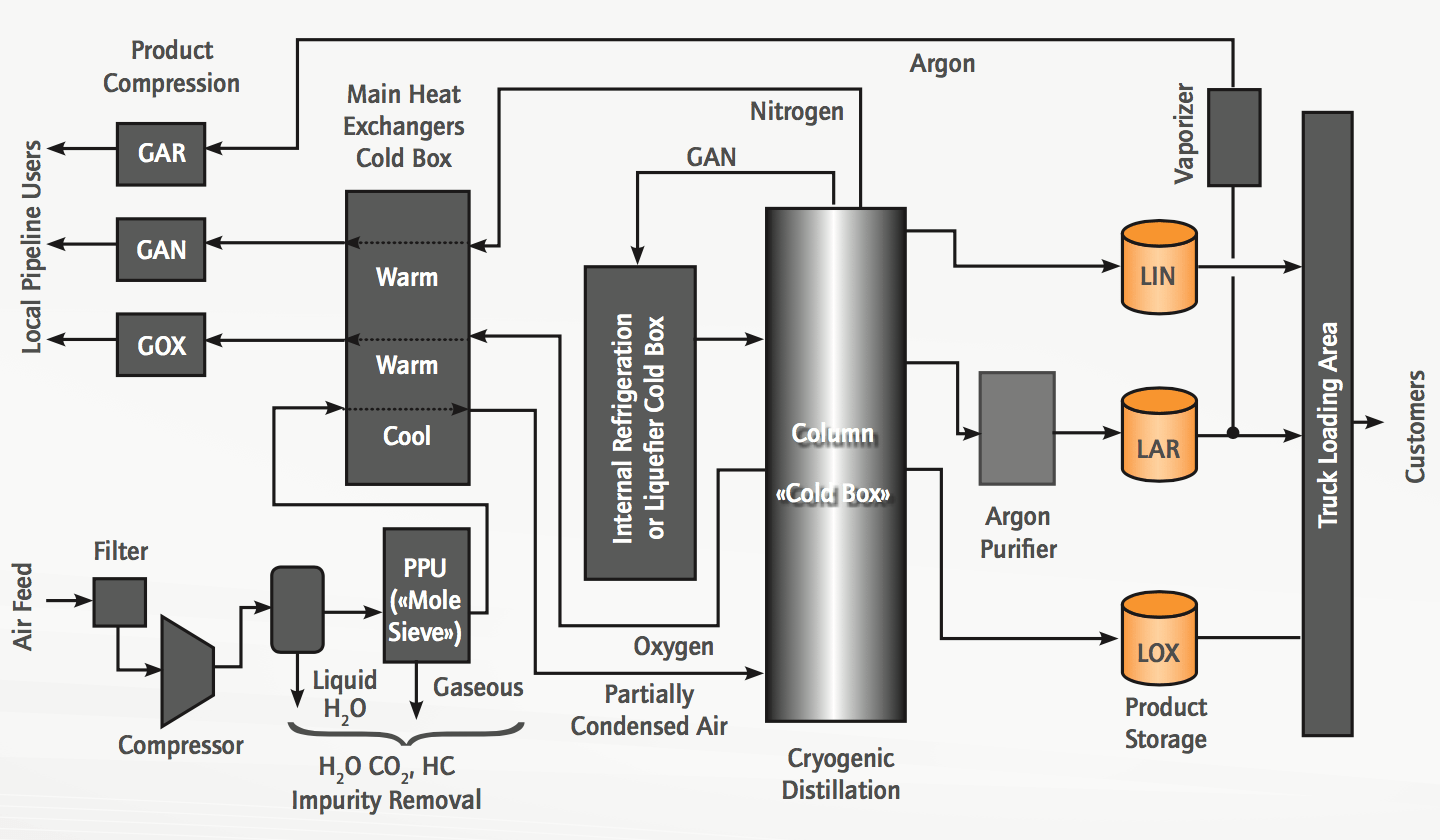

Cryogenic Distillation Of Air Chemical Engineering World A p n hysys is used to simulate cryogenic distillation to separate nit ogen from atmospheric air with the following goals. in aspen hysys, a steady state simulation of gan (gaseous nitrogen) production at a flow r te of 2100 nm3 h at 8 9 bar pressure was performed. The essential features of cryogenic engineering and to raise awareness on key design and construction issues of cryogenic devices and systems. the presentation of basic processes, implementation techniques and typical values for physical and engineering parameters is illustrated by applications to helium cryogenics. 1. 2.9 temperature profiles of hot air (—) and boiling o 2 ( ) from stage wise (left) and fractional length (right) views. locations of the boundary points in the fractional length view are defined by the value of f sh;f tp;and f sc. . . . .36 2.10 hot air stream temperature profile with stage wise model (—) and collocation. Cryogenic air separation is a well established technology. however, due to its associated energy intensity and hazardousness, new studies are always emerging on this topic. nevertheless, economic feasibility studies of cryogenic separation plants are still scarce. studies of this type are essential because installing an air separation unit can also be considered at the design stage of other.

Cryogenic Distillation Process The Engineer S Perspective 2.9 temperature profiles of hot air (—) and boiling o 2 ( ) from stage wise (left) and fractional length (right) views. locations of the boundary points in the fractional length view are defined by the value of f sh;f tp;and f sc. . . . .36 2.10 hot air stream temperature profile with stage wise model (—) and collocation. Cryogenic air separation is a well established technology. however, due to its associated energy intensity and hazardousness, new studies are always emerging on this topic. nevertheless, economic feasibility studies of cryogenic separation plants are still scarce. studies of this type are essential because installing an air separation unit can also be considered at the design stage of other. Toshihide horikawa, in computer aided chemical engineering, 2014. abstract. cryogenic distillation is very similar to other distillation systems except it is used to separate chemicals with very low boiling points (e.g. propylene propane mixture). in the case of cryogenic distillation, a refrigeration system must be coupled with the condenser. Cryogenic air separation processes are widely used for the large scale production of nitrogen and oxygen. the most widely used design for this process involves two distillation columns operating at different pressures. this work focuses on the selection of suitable cryogenic air separation process by evaluating seven alternative designs of the two column air separation process based on.

Cryogenic Distillation Process The Engineer S Perspective Toshihide horikawa, in computer aided chemical engineering, 2014. abstract. cryogenic distillation is very similar to other distillation systems except it is used to separate chemicals with very low boiling points (e.g. propylene propane mixture). in the case of cryogenic distillation, a refrigeration system must be coupled with the condenser. Cryogenic air separation processes are widely used for the large scale production of nitrogen and oxygen. the most widely used design for this process involves two distillation columns operating at different pressures. this work focuses on the selection of suitable cryogenic air separation process by evaluating seven alternative designs of the two column air separation process based on.

Comments are closed.