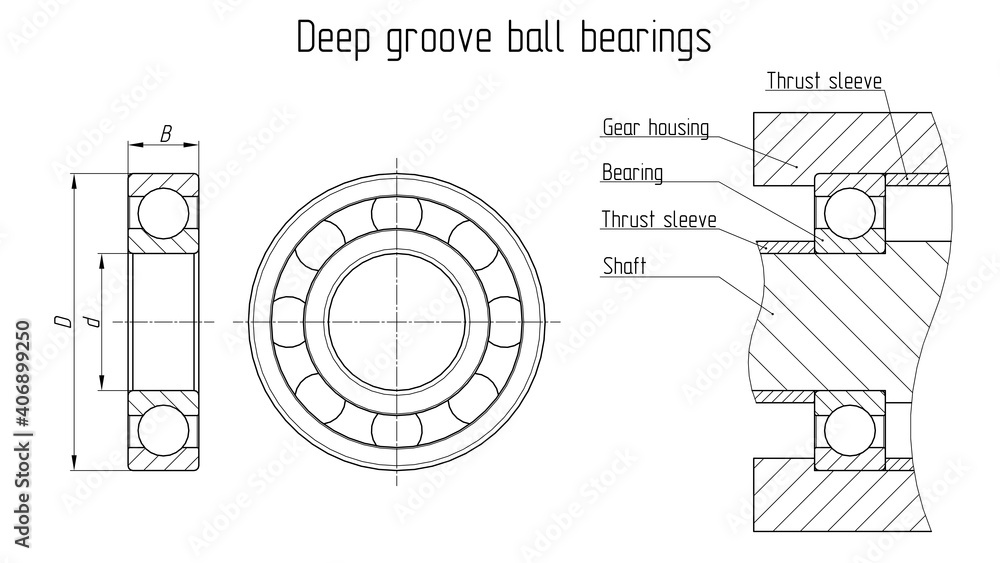

Deep Groove Ball Bearing General Drawing And Installation Diagram

Deep Groove Ball Bearing General Drawing And Installation Diagram Deep groove ball bearings single row, with or without filling slots open basic design (1) with shields with contact seals (2) with a sna p ring groove, with or without a snap ring angular contact ball bearings single row basic design f or single mounting design for universal matching (3) single row high precision basic design f or single. Widely used in a variety of fields, deep groove ball bearings are the most common type of bearing. deep groove ball bearings may include seals or shields as shown in table 2. 2. deep groove ball bearings also include bearings with snap rings for positioning when 9 ntn rolling bearings handbook 2 table 2.1 comparison of ball bearings and roller.

вђ Deep Groove Ball Bearing Details A Sketch B Cross Section A deep groove ball bearing is a type of rolling bearing that has deep raceway grooves on both the inner and outer rings. combined with the balls, these grooves allow the bearing to support radial and axial loads, making it versatile. the deep grooves also provide high stability and support high rotational speeds with low friction. Wide range of sizes and configurations. offered sizes range from 3 mm to 400 mm bore, and maximum outside diameter (o.d.) of 600 mm. timken continues to expand the offering of deep groove ball bear. ngs with larger sizes to be introduced. contact your timken sales representat. Deep groove ball bearings deep groove ball bearings are very widely used. a deep groove is formed on the inner and outer ring of the bearing enabling the bearing to sustain radial and axial loads in either direction as well as the complex loads which result from the combination of these forces. deep groove ball bearings are suitable. Of deep groove ball bearings from our vast selection. with our profitability programme (aip), onsite problem diagnosis, installation supervision and technical literature, our commitment goes way beyond just the delivery of the bearing. your advantages at a glance: › investment in research and development › continuous optimisation of quality.

Schematic Of Deep Groove Ball Bearing Download Scientific Diagram Deep groove ball bearings deep groove ball bearings are very widely used. a deep groove is formed on the inner and outer ring of the bearing enabling the bearing to sustain radial and axial loads in either direction as well as the complex loads which result from the combination of these forces. deep groove ball bearings are suitable. Of deep groove ball bearings from our vast selection. with our profitability programme (aip), onsite problem diagnosis, installation supervision and technical literature, our commitment goes way beyond just the delivery of the bearing. your advantages at a glance: › investment in research and development › continuous optimisation of quality. 0.0006 0.003 radian. 6. general operating cautions. slippage between the balls and raceways may occur when bearings are operated under small loads (about fr ≦ 0.01cor) and may cause smearing. this is most apparent when using large size deep groove ball bearings due to the large cage mass. please consult ntn engineering for further details. Deep groove ball bearings are the most widely used bearing type and are particularly versatile. they have low friction and are optimized for low noise and low vibration which enables high rotational speeds. they accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than other bearing types.

Sketch Of Deep Groove Ball Bearing Details Download Scientific Diagram 0.0006 0.003 radian. 6. general operating cautions. slippage between the balls and raceways may occur when bearings are operated under small loads (about fr ≦ 0.01cor) and may cause smearing. this is most apparent when using large size deep groove ball bearings due to the large cage mass. please consult ntn engineering for further details. Deep groove ball bearings are the most widely used bearing type and are particularly versatile. they have low friction and are optimized for low noise and low vibration which enables high rotational speeds. they accommodate radial and axial loads in both directions, are easy to mount, and require less maintenance than other bearing types.

Comments are closed.