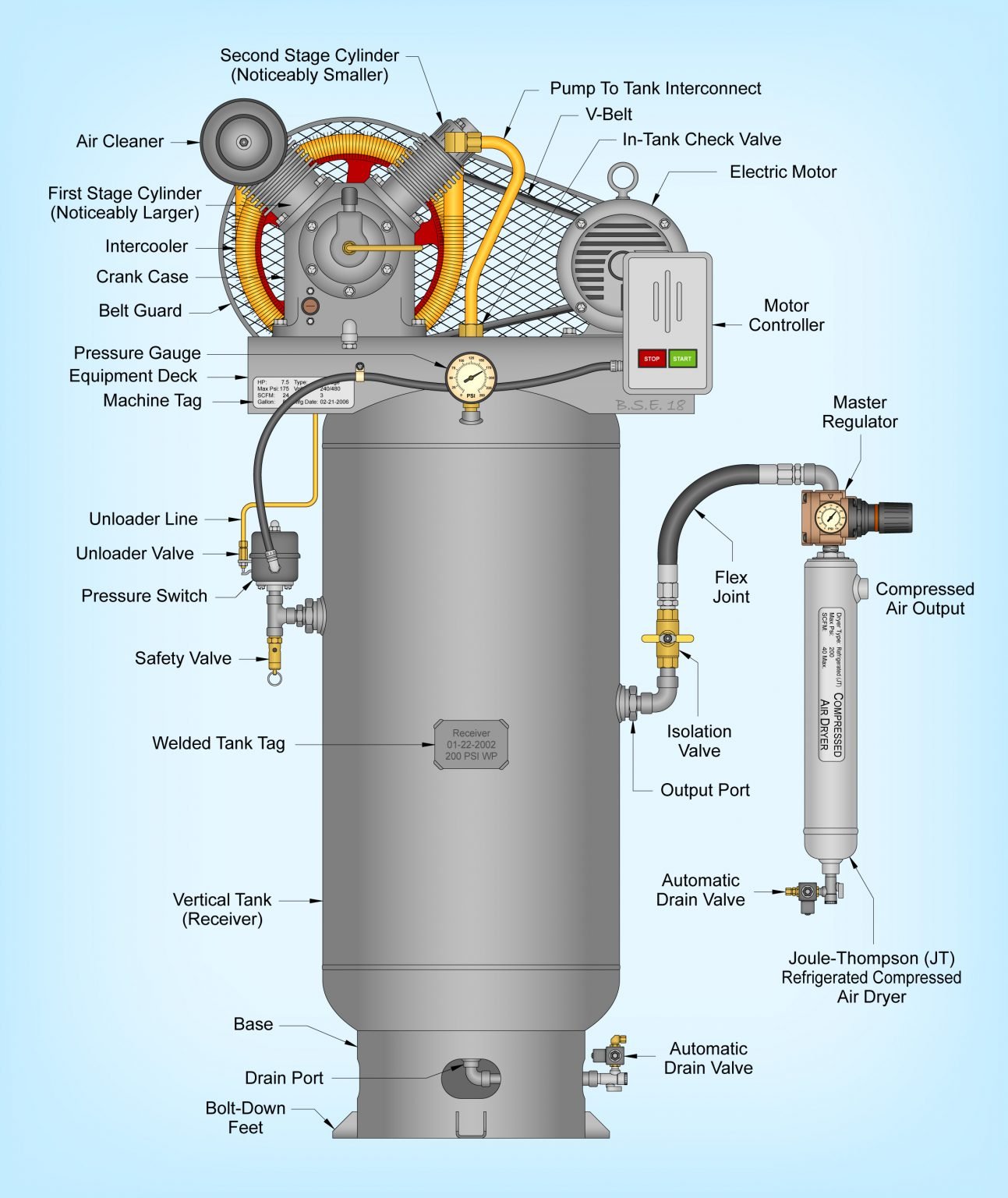

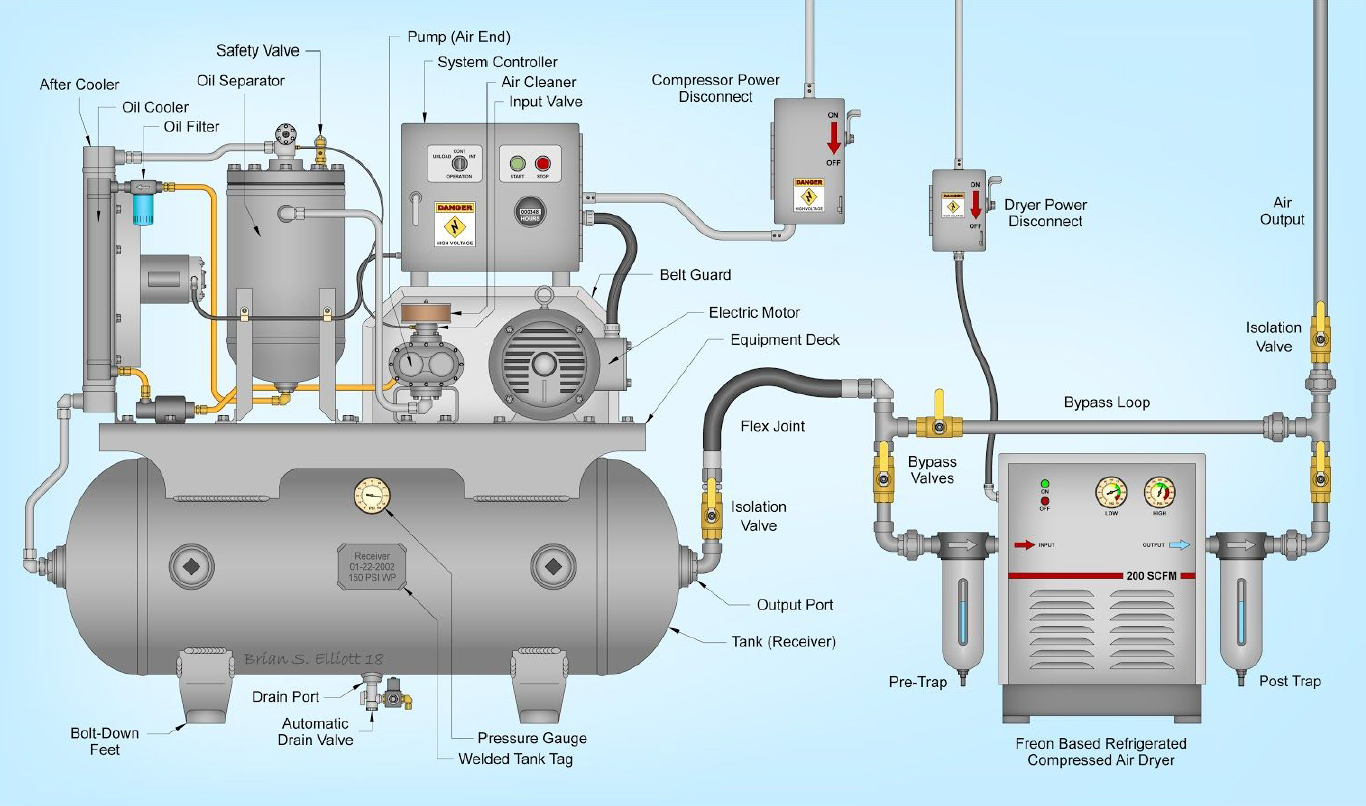

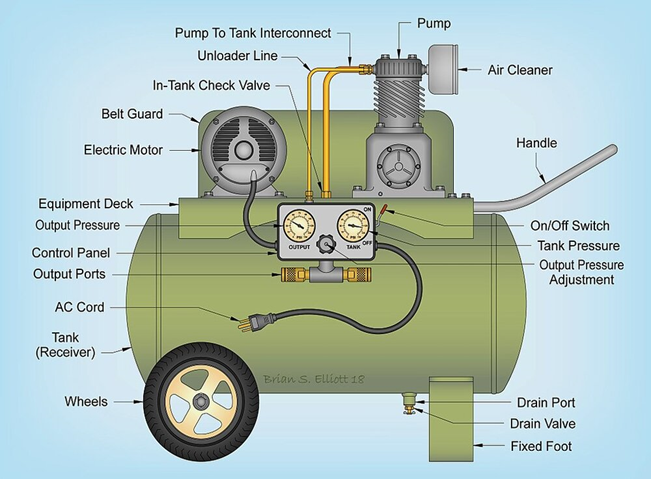

Diagram Of Air Compressor Parts

Parts Of An Air Compressor Diagram Guide Air Compressor Parts Integrated dryer (optional) 2. coolant filter 3. coolant separator cartridge 4. airend relief valve 5. coolant filter plug 6. sight glass 7. pilot valve 8. pressure switch. the basic anatomy of air compressors, expolded view diamgrams, breakdowns, primary parts of piston and rotary screw. Air compressors consist of many components to ensure that your system provides high quality compressed air, and so, it can often be difficult to understand the role of each component. this article will provide you with a few annotated diagrams of air compressor systems, with descriptions about each part to follow.

Diagram Of Air Compressor Parts Parts of the air end in a screw compressor include: rotors (screws): the air end contains two screws, a male rotor (drive rotor), which typically has fewer lobes, and a female rotor (driven rotor), which generally has more lobes and is driven by the male rotor. the interlocking helical rotors move in opposite directions, compressing the air. The diagrams of how an air compressor works show that it has three main parts: a motor, a pump, and a tank. the motor powers the pump, which compresses air and stores it in the tank. when you need to use the air, the tank releases it through a hose or nozzle. the pump also has several subparts, including an intake valve, a piston, and a. Oil breather oil breather bolt aftercooler top cap gasket aftercooler top cap aftercooler bottom cap gasket aftercooler bottom cap connecting rod insert (half) aftercooler safety valve (1 4" npt 225 psi) aftercooler inlet filter assembly filter element oil drain plug (3 8" npt) cooler cap bolt (m6 x 20) cooler cap nut. Important parts of a reciprocating air compressor are as follows: cylinder head, suction intake valve, delivery valve, cylinder liner wall cooling water jacket, compressor casing, crank case, piston, connecting rod, crank shaft, main bearings, bed plate or bottom structure, foundation, lubricating oil strainer, stage relief valves, intercoolers, after coolers, suction filter, and other.

Schematic Diagram Of Air Compressor Oil breather oil breather bolt aftercooler top cap gasket aftercooler top cap aftercooler bottom cap gasket aftercooler bottom cap connecting rod insert (half) aftercooler safety valve (1 4" npt 225 psi) aftercooler inlet filter assembly filter element oil drain plug (3 8" npt) cooler cap bolt (m6 x 20) cooler cap nut. Important parts of a reciprocating air compressor are as follows: cylinder head, suction intake valve, delivery valve, cylinder liner wall cooling water jacket, compressor casing, crank case, piston, connecting rod, crank shaft, main bearings, bed plate or bottom structure, foundation, lubricating oil strainer, stage relief valves, intercoolers, after coolers, suction filter, and other. An air compressor flow diagram is a visual representation that illustrates the various components and processes involved in the operation of an air compressor system. it provides a comprehensive overview of how air compressors function and how they generate compressed air for various applications. the flow diagram typically includes key. Advantages of reciprocating compressor. 1. piston type compressors are available in a wide range of capacity and pressure. 2. very high air pressure (250 bar) and air volume flow rate is possible with multi staging. 3. better mechanical balancing is possible by a multistage compressor by proper cylinder arrangement. 4.

Campbell Hausfeld Hx5100 Parts Diagram For Air Compressor Parts An air compressor flow diagram is a visual representation that illustrates the various components and processes involved in the operation of an air compressor system. it provides a comprehensive overview of how air compressors function and how they generate compressed air for various applications. the flow diagram typically includes key. Advantages of reciprocating compressor. 1. piston type compressors are available in a wide range of capacity and pressure. 2. very high air pressure (250 bar) and air volume flow rate is possible with multi staging. 3. better mechanical balancing is possible by a multistage compressor by proper cylinder arrangement. 4.

Air Compressor Components Diagram

Comments are closed.