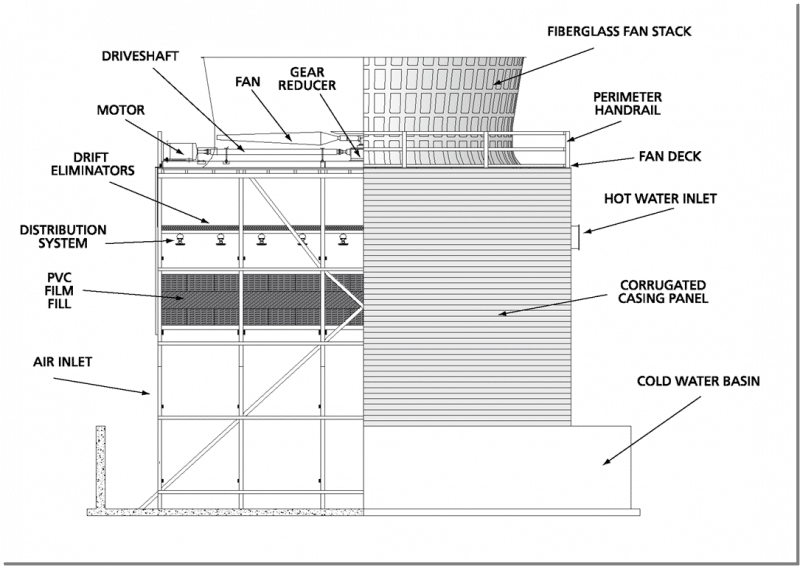

Diagram Of Counterflow Cooling Tower

The Counterflow Cooling Tower A Quick Intro Linquip Counterflow cooling towers. counterflow cooling towers have water flowing vertically downward while the air flows vertically upward, opposite to the water flow direction. the water is sprayed and distributed over a series of fill materials, and the airflow is induced by mechanical fans at the top of the tower. As the air flow in the counterflow cooling tower system flows vertically, it is not reasonable to accept the container's gravity flow like in the crossflow cooling tower system. so to replace the situation, the counterflow cooling tower system uses pressurized spray technique, usually pipe kind, to diffuse the water to the peak of the fill media.

Counterflow Cooling Towers Midwest Cooling Towers Counterflow cooling tower diagram difference between crossflow and counterflow cooling towers: in counterflow cooling tower system processes, the air vertically flows upwards, counter to the water flow in the fill media. due to the air flowing vertically, it's not possible to use the basin's gravity flow like in crossflow towers. The water is exposed to air as it flows throughout the cooling tower. the air is being pulled by an motor driven electric “cooling tower fan”. when the air and water come together, a small volume of water evaporates, creating an action of cooling. the colder water gets pumped back to the process equipment that absorbs heat or the condenser. The two diagrams below show the design differences between crossflow, on the right, and counterflow, on the left, of natural draft cooling towers. the tower can cool up to 480,000 gallons of water per minute. The counterflow cooling tower is a type of cooling tower design that offers the maximum thermal performance for its area of occupation. the fill media is horizontally installed beneath the hot water distribution basin, and the cooling process is carried out as the air passes through the fill absorbing the heat from the water flowing down the.

Induced Draft Counter Flow Cooling Tower Explained Savree The two diagrams below show the design differences between crossflow, on the right, and counterflow, on the left, of natural draft cooling towers. the tower can cool up to 480,000 gallons of water per minute. The counterflow cooling tower is a type of cooling tower design that offers the maximum thermal performance for its area of occupation. the fill media is horizontally installed beneath the hot water distribution basin, and the cooling process is carried out as the air passes through the fill absorbing the heat from the water flowing down the. The cool cooling water is heated by the process and its temperature increases. the warm cooling water is then pumped back to the cooling tower to be cooled. counter flow cooling tower process diagram. incoming warm water enters the distribution manifold and is discharged through spray nozzles inside the tower. spray nozzles spray the warm water. Showers inside cooling tower forced draft counter flow package type cooling tower. in a counterflow design, the air flow is directly opposite to the water flow (see diagram at left). air flow first enters an open area beneath the fill media, and is then drawn up vertically.

Comments are closed.