Double Cylinder Steam Turbine Axial Flow Steam Turbine China Steamо

Double Cylinder Steam Turbine Axial Flow Steam Turbineо The reheated steam is returned to the ip turbine and is exhausted to the lp turbine at around 10 bar (145 psi), 180⁰c (356⁰f). finally, the lp turbine will exhaust to the condenser, which is held at around 720mm hg ( 0.95 bar 13.77 psi) vacuum. summary: hp turbine inlet – 180 bar (2610 psi), 540⁰c (1,000⁰f). The lp turbine is a pressure compounded, either single or dual axial flow, condensing reaction turbine. division of steam flow: on ships where space is a consideration, the lp turbine is designed to be a dual flow turbine. steam enters the center of the turbine from the crossover pipe and flows across the reaction blading in two opposite.

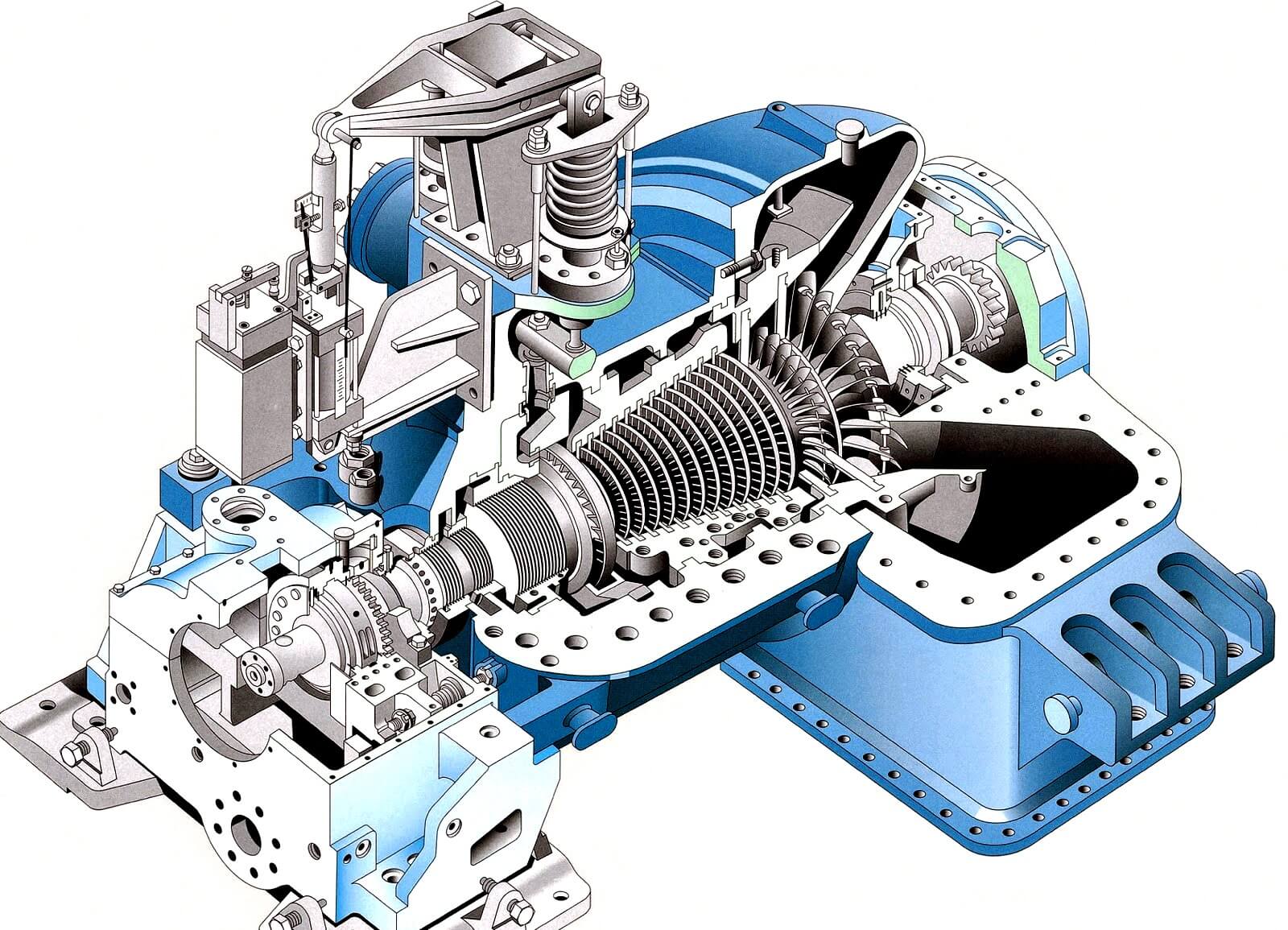

Steam Turbine Parts And Components Linquip Industrial steam turbine. the sst 400 is a single casing steam turbine, providing geared or direct drive to 50 and 60 hz generators, or to compressors and pumps. the symmetrical casing with horizontal joint flange enables the sst 400 to accept short start up times and rapid load changes. the modular package design allows a wide variety of. The usual turbine has four main parts. the rotor is the rotating part which carries the blades or buckets. the stator consists of a cylinder and casing within which the rotor turns. the turbine has a base or frame, and finally there are nozzles or flow passages which expand the flow. the cylinder, casing, and frame are often combined. Chapter eight: axial flow turbines. historically, the first axial turbine utilizing a compressible fluid was a steam turbine. gas turbines were later developed for engineering applications where compactness is as important as performance. however, the successful use of this turbine type had to wait for advances in the area of compressor. Directly coupled steam turbines in combined cycle applications must provide the perform ance and flexibility required for integration. mdt's, 2,500 hp to 80,000 hp bfpt's, 3 35 mw. single or double end drive inlet steam up to 1800 psig 1000°f (12 kg cm2g 538°c) applications. utility boiler reactor feed pumps.

Comments are closed.