Dwight Hard To Start And Stalls Has Fuel Has Spark Valve Lash Perhaps Lets Check Part 1 Of 2

Dwight Hard To Start And Stalls Has Fuel Has Spark о Dwight is our 2018 sportsman ace 570, and it has developed a new problem where it is very hard to start when cold, and it won't idle until it gets warmed up . Rotate the engine so the number one intake is ¾ of the way closed. spin the exhaust pushrod to make sure it is free. once again, insert the proper feeler gauge above the exhaust valve stem and below the rocker tip. you want the fit to be the same as how we checked the intake, snug, not too tight not to loose.

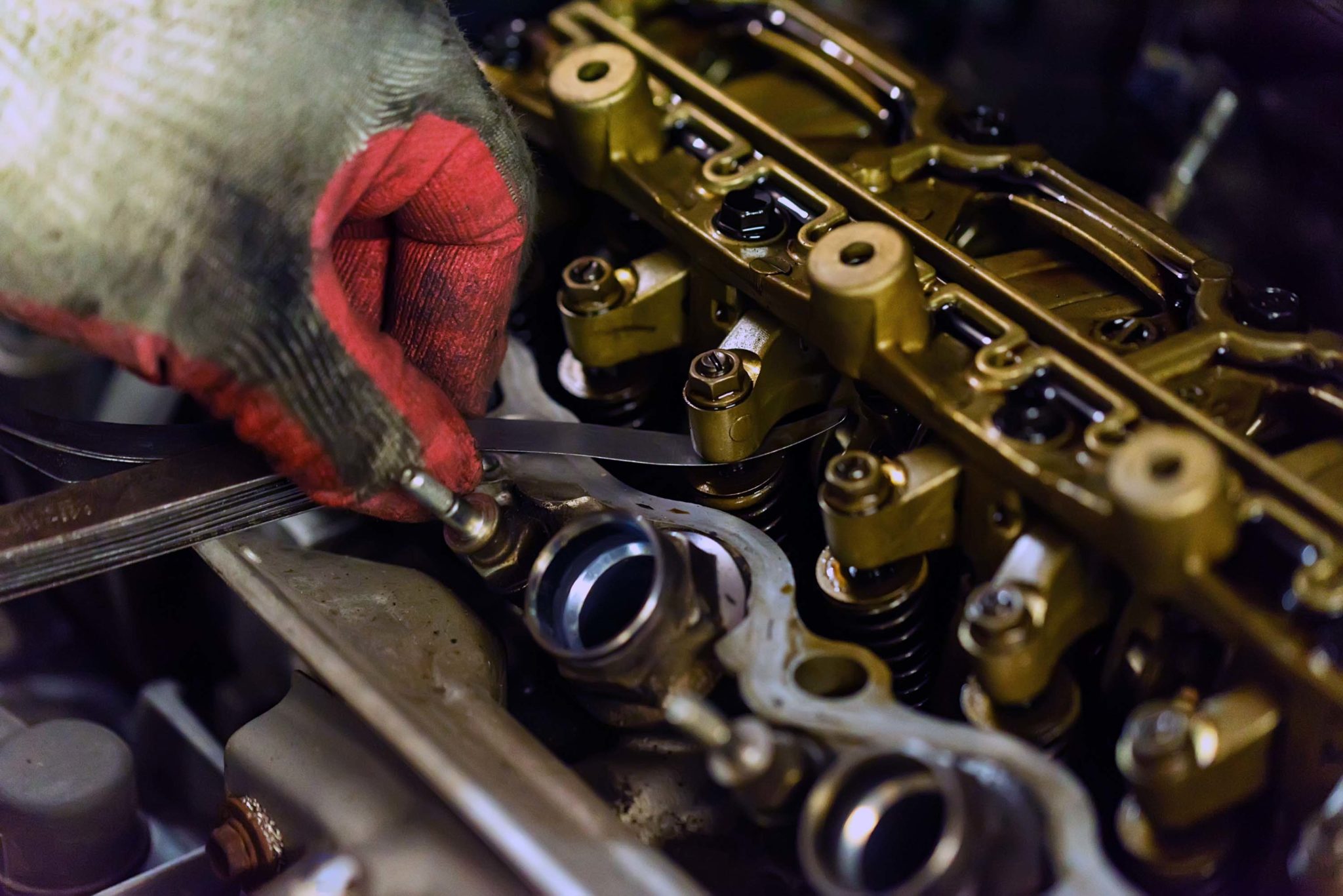

A Comprehensive Guide To Valve Lash In The Garage With Carparts To prepare for adjusting the valve lash, start by removing the hood for better access to the engine components. this step allows you to reach the valves and rocker arms easily. gather the necessary tools such as a wrench, feeler gauge, and a torque wrench to aid in the adjustment process. prioritize important safety precautions by disconnecting. The valve lash is the empty space between the engine’s valve train parts. it is commonly known as valve clearance. valve lash measurement area differs from vehicle to vehicle based on engine design. for instance, on overhead camshaft engines, the measurement is taken between the camshaft follower and the camshaft or between the tappet and the. Once you've determined that the valve you are checking is fully closed, actually checking the lash is the easy part. simply use a feeler gauge and slide the tab of the correct thickness between. Check the lash the same way every time otherwise it will be all over the place. you won’t know when you have a problem.” check valve lash weekly. david reher says, “my number one rule of prevention is to never ignore a significant change in valve lash. if one valve suddenly has 20 thousandths more lash than the other valves, find out why.

Valve Lash What Is It And Valve Lash Adjustment вђў Road Sumo Once you've determined that the valve you are checking is fully closed, actually checking the lash is the easy part. simply use a feeler gauge and slide the tab of the correct thickness between. Check the lash the same way every time otherwise it will be all over the place. you won’t know when you have a problem.” check valve lash weekly. david reher says, “my number one rule of prevention is to never ignore a significant change in valve lash. if one valve suddenly has 20 thousandths more lash than the other valves, find out why. An engine equipped with a hydraulic camshaft, does not require a feeler gauge. when adjusting the valve lash on an engine with hydraulic lifters, you are not really setting the lash or clearance. you’re actually setting the preload on the lifter, through the pushrod and rocker arm. the traditional adjustment on a hydraulic lifter, is zero lash. This is zero lash. to set preload, merely tighten the adjuster nut another half turn after zero lash. if you are setting the lash on a mechanical lifter camshaft, use the appropriate feeler gauge between the valve tip and the rocker arm and adjust the lash until there is a reasonable tug or pull on the feeler gauge.

Setting Valve Lash How To Check And Set Your Lash The Right Way An engine equipped with a hydraulic camshaft, does not require a feeler gauge. when adjusting the valve lash on an engine with hydraulic lifters, you are not really setting the lash or clearance. you’re actually setting the preload on the lifter, through the pushrod and rocker arm. the traditional adjustment on a hydraulic lifter, is zero lash. This is zero lash. to set preload, merely tighten the adjuster nut another half turn after zero lash. if you are setting the lash on a mechanical lifter camshaft, use the appropriate feeler gauge between the valve tip and the rocker arm and adjust the lash until there is a reasonable tug or pull on the feeler gauge.

Comments are closed.