Failure Mode And Effects Analysis Fmea Method Operational 52 Off

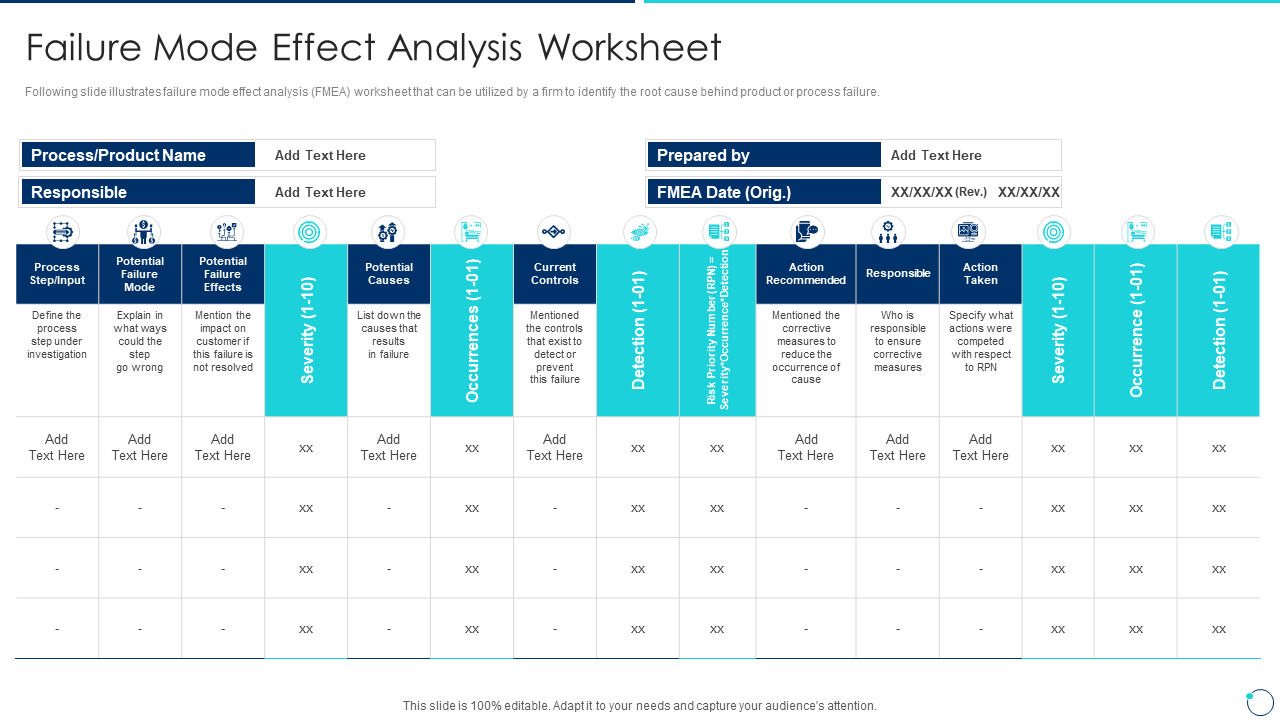

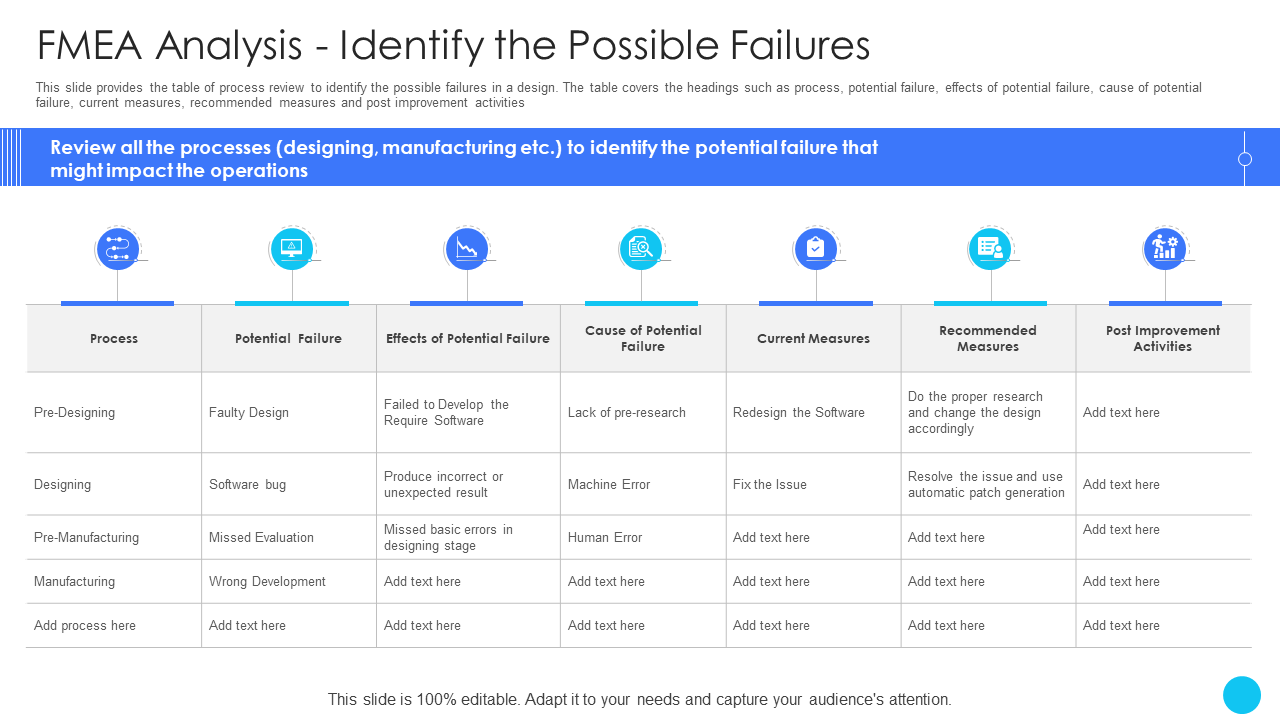

Failure Mode And Effects Analysis Fmea Method Operational Fmea is a systematic and proactive risk management technique for identifying and mitigating potential system, process, or product failures. the technique is widely used across industries to analyze potential failure modes, their causes, and their effects on overall operation. fmea allows businesses to prioritize and address the most critical. Begun in the 1940s by the u.s. military, failure modes and effects analysis (fmea) is a step by step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. it is a common process analysis tool. "failure modes" means the ways, or modes, in which something might fail.

Failure Mode And Effects Analysis Fmea Method Operational Failure mode and effects analysis, commonly abbreviated as fmea, is a structured, step by step, proactive approach to identifying and analyzing all the conceivable failures in a product, process, design, or service. conceived during the 1950s within the aerospace industry, this technique has since become a valuable tool across multiple industries. Identify failure modes—all item and interface failure modes must be identified, understanding that any effects upon function, mission, or system must be determined; analyze failure effects causes—accomplished on each item in the rbd. consequences of each failure mode on operation and the next higher level should be identified. 1.1. aims. the fmea (failure mode and effects analysis) is an analytical method of preventive quality management in product and process development. it is used to identify and evaluate risks in good time, and to propose and implement suitable actions with the aim of improving products or processes and avoiding failure costs (recalls, yield). Qi essentials toolkit:failure modes and effects analysis (fmea)failure modes and effects analysis (fmea) is a tool for conducting a sys. ematic, proactive analysis of a process in which harm may occur. in an fmea, a team representing all areas of the process under review convenes to predict. and record where, how, and to what extent the system.

Comments are closed.