Failure Mode Effects Analysis Fmea

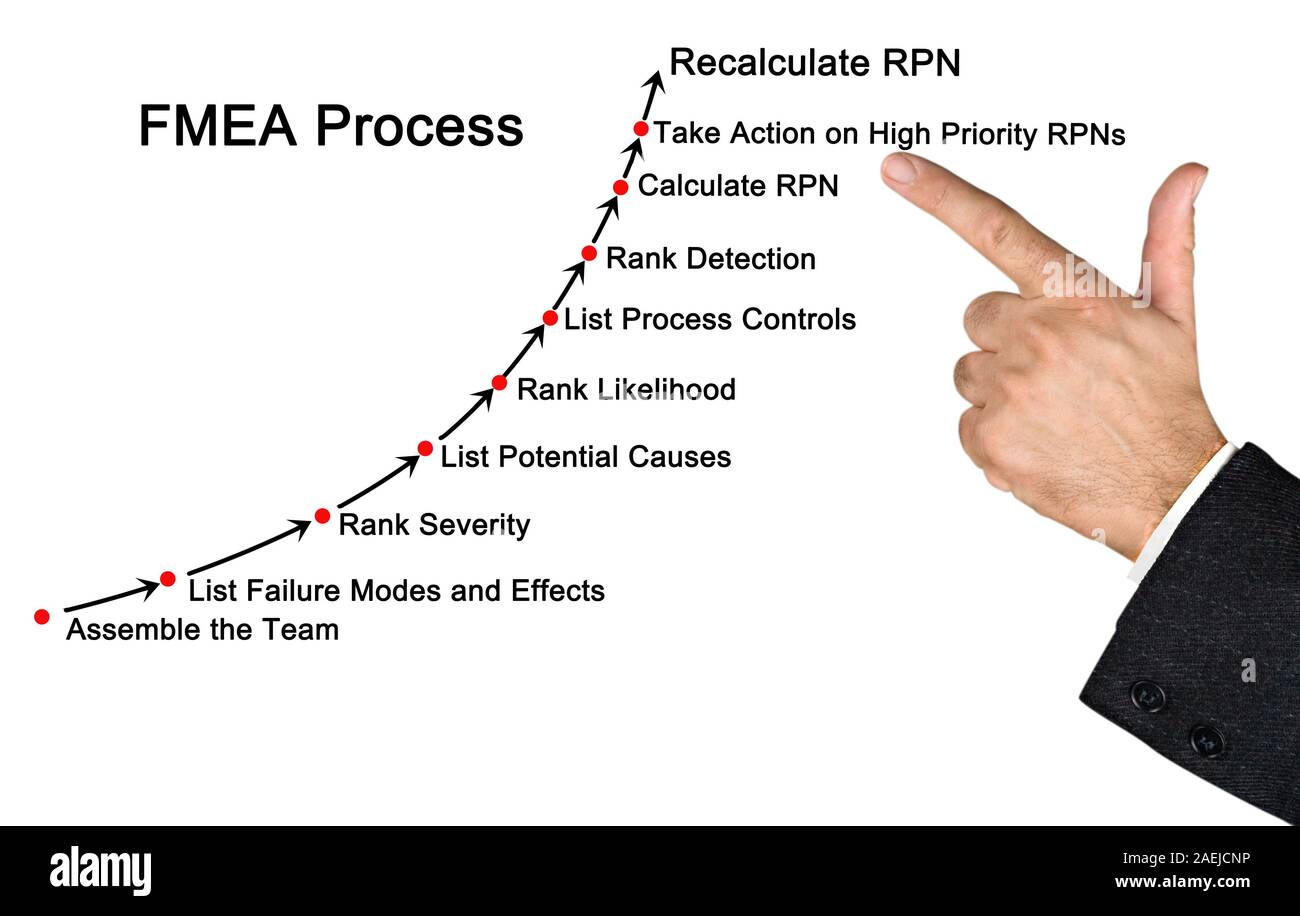

Fmea Failure Mode And Effects Analysis Process Vector Image Begun in the 1940s by the u.s. military, failure modes and effects analysis (fmea) is a step by step approach for identifying all possible failures in a design, a manufacturing or assembly process, or a product or service. it is a common process analysis tool. "failure modes" means the ways, or modes, in which something might fail. Failure mode and effects analysis, commonly abbreviated as fmea, is a structured, step by step, proactive approach to identifying and analyzing all the conceivable failures in a product, process, design, or service. conceived during the 1950s within the aerospace industry, this technique has since become a valuable tool across multiple industries.

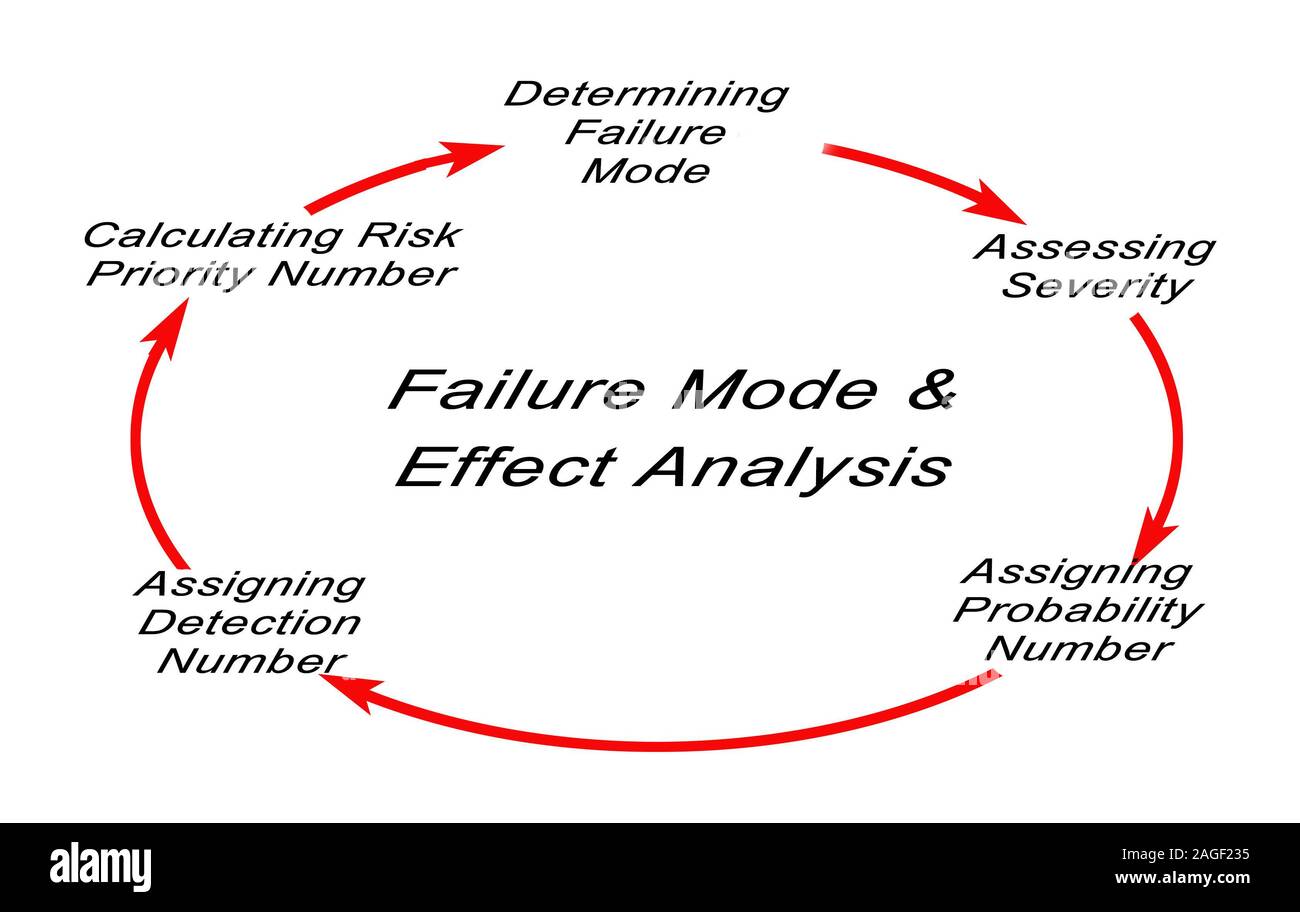

Failure Mode And Effects Analysis Fmea Process Stock Photo Alamy Slides: guide fmea by learn lean sigma. failure mode and effects analysis (fmea) is a structured methodology used to identify and mitigate risks caused by system or process failures. with this guide we will explain how to identify failure modes, assess their severity, determine causes and effects, estimate occurrence, evaluate existing controls. Failure mode and effects analysis (fmea; often written with "failure modes" in plural) is the process of reviewing as many components, assemblies, and subsystems as possible to identify potential failure modes in a system and their causes and effects. for each component, the failure modes and their resulting effects on the rest of the system are recorded in a specific fmea worksheet. Failure mode and effects analysis, or fmea, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing process. developed in the 1950s, fmea was one of the earliest structured reliability improvement methods. Failure modes & effects analysis (fmea) is a risk management tool that identifies and quantifies the influence of potential failures in a process. fmea analyzes potential failures using three criteria: once assessed, prioritized failures are addressed with mistake proofing for preventable failures and contingency plans for unpreventable risks.

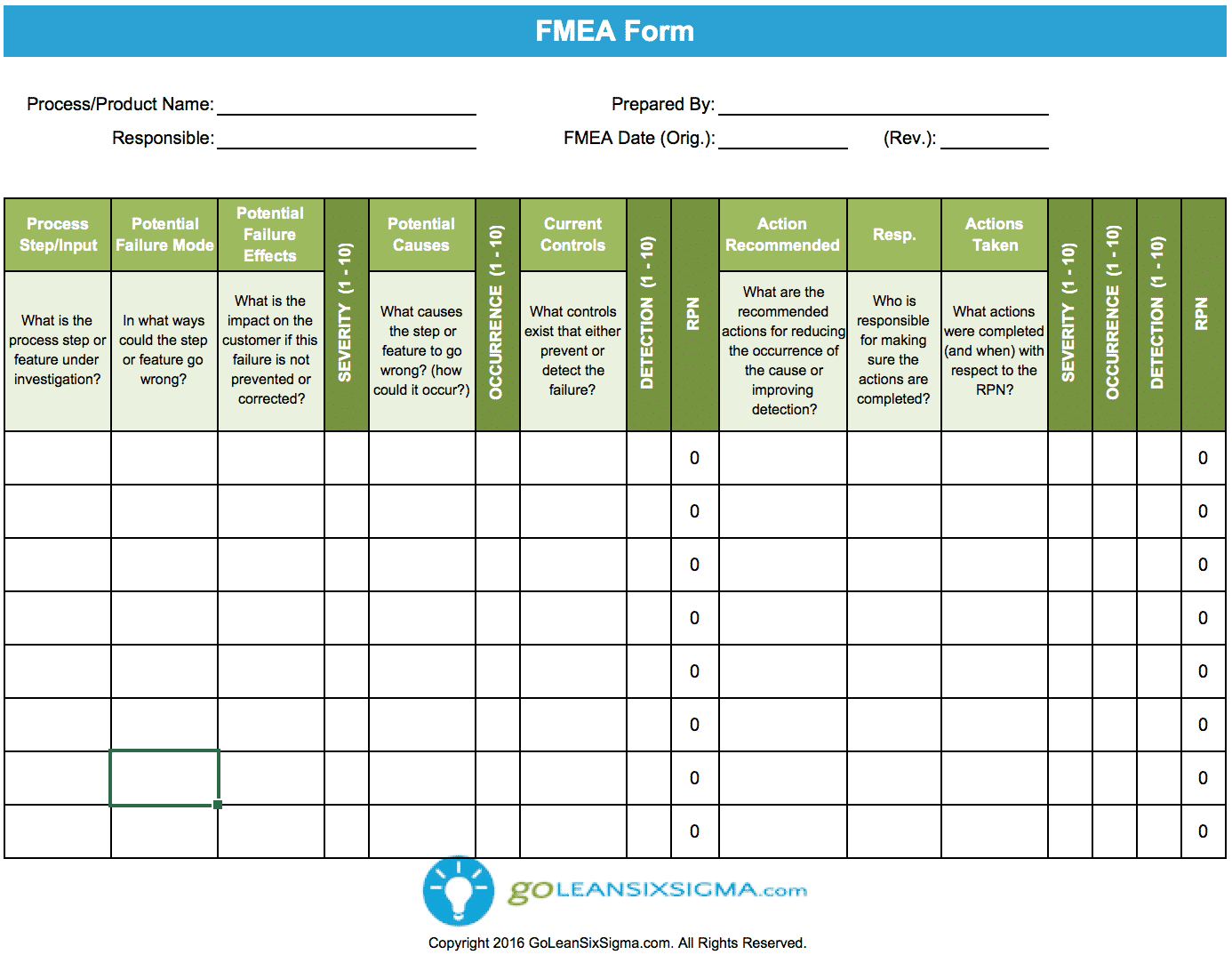

Failure Modes Effects Analysis Fmea Template Example Failure mode and effects analysis, or fmea, is a methodology aimed at allowing organizations to anticipate failure during the design stage by identifying all of the possible failures in a design or manufacturing process. developed in the 1950s, fmea was one of the earliest structured reliability improvement methods. Failure modes & effects analysis (fmea) is a risk management tool that identifies and quantifies the influence of potential failures in a process. fmea analyzes potential failures using three criteria: once assessed, prioritized failures are addressed with mistake proofing for preventable failures and contingency plans for unpreventable risks. The failure mode and effects analysis (fmea) method has been used for decades to conduct technical risk analysis, identify, and reduce failures and improve safety in products and processes. the technique varies by industry and application, but the goal is to prevent injury to the end user and maintain compliance with safety regulations. Qi essentials toolkit:failure modes and effects analysis (fmea)failure modes and effects analysis (fmea) is a tool for conducting a sys. ematic, proactive analysis of a process in which harm may occur. in an fmea, a team representing all areas of the process under review convenes to predict. and record where, how, and to what extent the system.

How To Conduct A Failure Modes And Effects Analysis Fictiv Hardware The failure mode and effects analysis (fmea) method has been used for decades to conduct technical risk analysis, identify, and reduce failures and improve safety in products and processes. the technique varies by industry and application, but the goal is to prevent injury to the end user and maintain compliance with safety regulations. Qi essentials toolkit:failure modes and effects analysis (fmea)failure modes and effects analysis (fmea) is a tool for conducting a sys. ematic, proactive analysis of a process in which harm may occur. in an fmea, a team representing all areas of the process under review convenes to predict. and record where, how, and to what extent the system.

Failure Mode And Effects Analysis Fmea Stock Photo Alamy

Comments are closed.