Forklift Warning Lights Meanings Detailed Full List

Forklift Warning Lights Meanings Detailed Full List Here is a list of forklift warning lights and their meanings. red light: this indicates a stop or danger ahead. you should always heed this warning and come to a complete stop as soon as possible. amber light: this light usually means that something is wrong with the engine or transmission. you should pull over and investigate the problem as. December 18, 2023. forklift warning light symbols are essential for workers in springs and logistics operations. these warning lights keep them from the surrounding area and are expressed in red. since the red color means " danger," a correct use is offered. you can purchase such lights by visiting the dealers in your region.

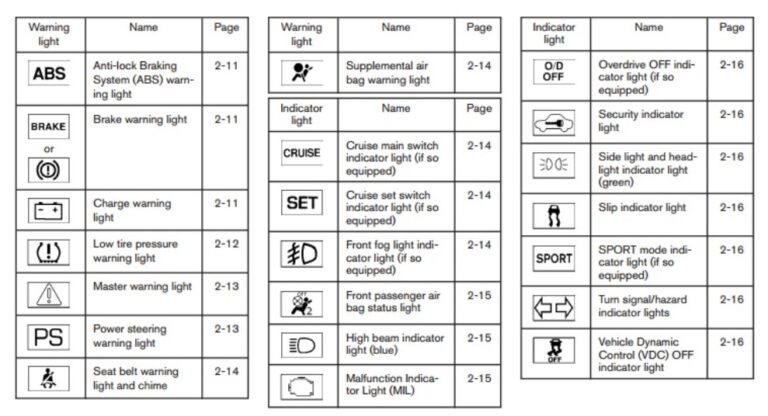

Forklift Warning Lights Meanings Detailed Full List Here’s a quick guide to the most common forklift warning light symbols and what you should do when you see them: a red light with an exclamation point means the engine oil level is low. check the oil level as soon as possible and add more if necessary. a yellow light with an exclamation point means the coolant level is low. 24 common forklift instrument panel warning lights. meaning and symbols of the most common 24 warning lights on the truck instrument panel. low engine oil pressure indicator light. the parking brake engaged indicator light. hydraulic oil filter clogged indicator light. low hydraulic oil level indicator light. Key forklift warning indicators. temperature indicator warning light: this symbol resembles that found in cars, indicating the engine’s temperature. a red zone warns of overheating, prompting. Lift lockout indicator: often symbolized by a forklift or lift icon with a cross over it, this warning light indicates that the lifting mechanism is temporarily locked for safety reasons, possibly due to a malfunction or a specific safety protocol activation. operators need to address the underlying issue before the lifting function is restored.

Comments are closed.