Gd T Pdf Engineering Tolerance Geometry

Gd T Pdf Engineering Tolerance Geometry International standard to specify form, fit and function of parts. ansi y 14.5, iso 1101. significant improvement over traditional tolerancing. focuses on 3d part geometry features in addition to 2d drawings. a typical part drawing. Gd&t and mechanical tolerancing in the past 12 years. he has also written numerous articles and design guides on optical and mechanical tolerancing. paul has asme certification as a senior level gd&t professional. he is a subject matter expert (sme3) to asme’s statistical tolerancing technical subcommittee, a member of asme’s geometric.

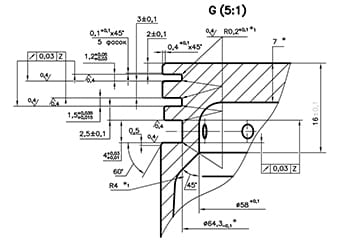

Gd T Tolerances Pdf Engineering Tolerance Geometry Asme y14.5 2018: geometric dimensioning and tolerancing. asme y14.5.1 2019: mathematical definition of dimensioning and tolerancing principles. asme y14.41 2019 digital product definition data practice. asme y14.46 2022 product definition for additive manufacturing. clearance holes for fasteners. The same part that fails with conventional tolerances may pass with gd&t tolerances. the figure below illustrates this issue. notice that a square tolerance zone of .500" will allow a hole center location .707" away from the center if it is located in the squares' corner (diagonally). remembering that a gd&t tolerance value is. Geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. it is an important tool for ensuring the interchangeability, functional accuracy, and reliability of manufactured components. gd&t is. Tolerance zone improvement with gd&t a round tolerance zone derived from an existing square tolerance zone results in 57% more area. the 57% increase in usable tolerance (shaded areas) derived from geometric tolerancing, would not be acceptable in coordinate tolerancing situations. .005 sq.010 sq Ø .014 the small red crosses represent a few of the.

Basics Of Gd T Manual 2 Day Pdf Engineering Tolerance Geometry Geometric dimensioning and tolerancing (gd&t) is a system of symbols and standards used in engineering drawings and models to specify the required form, size, orientation, and location of parts and features. it is an important tool for ensuring the interchangeability, functional accuracy, and reliability of manufactured components. gd&t is. Tolerance zone improvement with gd&t a round tolerance zone derived from an existing square tolerance zone results in 57% more area. the 57% increase in usable tolerance (shaded areas) derived from geometric tolerancing, would not be acceptable in coordinate tolerancing situations. .005 sq.010 sq Ø .014 the small red crosses represent a few of the. Features shown perpendicular, coaxial or symmetrical to each other must be controlled for location or orientation otherwise the drawing is incomplete. in other words fig. 5 1 is an incomplete drawing. fig. 5 8 shows the meaning of rule #1 for an external cylinder (pin or shaft) and an internal cylinder (hole). Gd&t represents a significant improvement over traditional dimensioning methods in describing the form, fit, and function of parts. gd&t is considered to be a mathematical language that is very precise. it describes each work piece in three “zones of tolerance” that are then described relative to the.

Gd T Complete Guide To Understand Geometric Dimensioning And Features shown perpendicular, coaxial or symmetrical to each other must be controlled for location or orientation otherwise the drawing is incomplete. in other words fig. 5 1 is an incomplete drawing. fig. 5 8 shows the meaning of rule #1 for an external cylinder (pin or shaft) and an internal cylinder (hole). Gd&t represents a significant improvement over traditional dimensioning methods in describing the form, fit, and function of parts. gd&t is considered to be a mathematical language that is very precise. it describes each work piece in three “zones of tolerance” that are then described relative to the.

Types Of Geometric Tolerances Gd T Fundamentals Keyence America

Comments are closed.