How Can Sanitary Diaphragm Valves Be Used Properly Adamant Valves

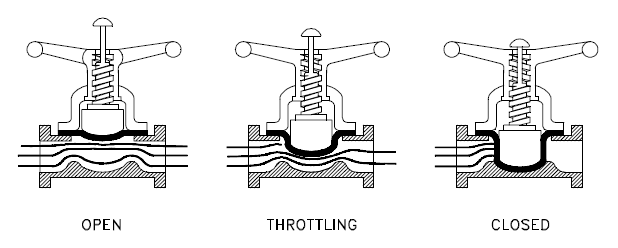

How Can Sanitary Diaphragm Valves Be Used Properly Adamant Valves The sanitary diaphragm valve has two main advantages, one is that the valve does not require a separate stem packing seal structure, and the diaphragm acts as a stem seal while cutting off the medium; the other is that the flexible diaphragm is reliable enough to shut off even the liquid. A sanitary diaphragm valve is considered a highly hygienic valve due to its mode of operation. this technique is called “input from above.”. the upper inlet facilitates the welding and extraction of the clamps during the maintenance of the valve. sanitary diaphragm valves are the preferred choice of valves used in the pharmaceutical industry.

How To Maintain The Sanitary Diaphragm Valve Properly Adamant Valve Sanitary butterfly valves regulate flow or control flow rate in large diameter pipes. sanitary choke valves are effective for high pressure drops found in oil and gas wellheads. sanitary check valves allow fluid to pass through in a single direction only. sanitary diaphragm valves are often used in the pharmaceutical and food industries. Advantages. the advantage of the sanitary diaphragm valve is that its operating mechanism is separated from the medium passage, which not only ensures the purity of the working medium, but also reduces the possibility of the medium in the pipeline impacting the working parts of the operating mechanism. in addition, there is no need for any form. Valve assembly. both of the assembly and disassembly are important for the maintenance of the sanitary diaphragm valve. if the assembly is failed, a terrible result may happen that the diaphragm is damaged, the valve is leaked and the medium is contaminated. so make sure you have tightened and retightened the valve in the assembly process. A sanitary diaphragm valve is considered a highly hygienic valve due to its mode of operation. this technique is called “input from above.”. the upper inlet facilitates the welding and the extraction of the clamps during the maintenance of the valve. sanitary diaphragm valves are the preferred choice of valves used in the pharmaceutical.

Comments are closed.