How Far Will Copper Interconnects Scale

How Far Will Copper Interconnects Scale So how far does copper interconnect scale? in direct comparison with ruthenium, a recent study identified the crossover point from copper to ruthenium in terms of resistivity as being just below a 300nm2, around 17 x 17nm (see figure 3). there are different ways of fabricating air gaps, including partial gap fill or using sacrificial materials. How far will copper interconnects scale? creative methods keep extending the performance of copper lines and vias. challenges in backside power delivery bpd boosts performance, but requires wafer bonding, substrate thinning, and possibly new interconnect metals. hybrid bonding moves into the fast lane.

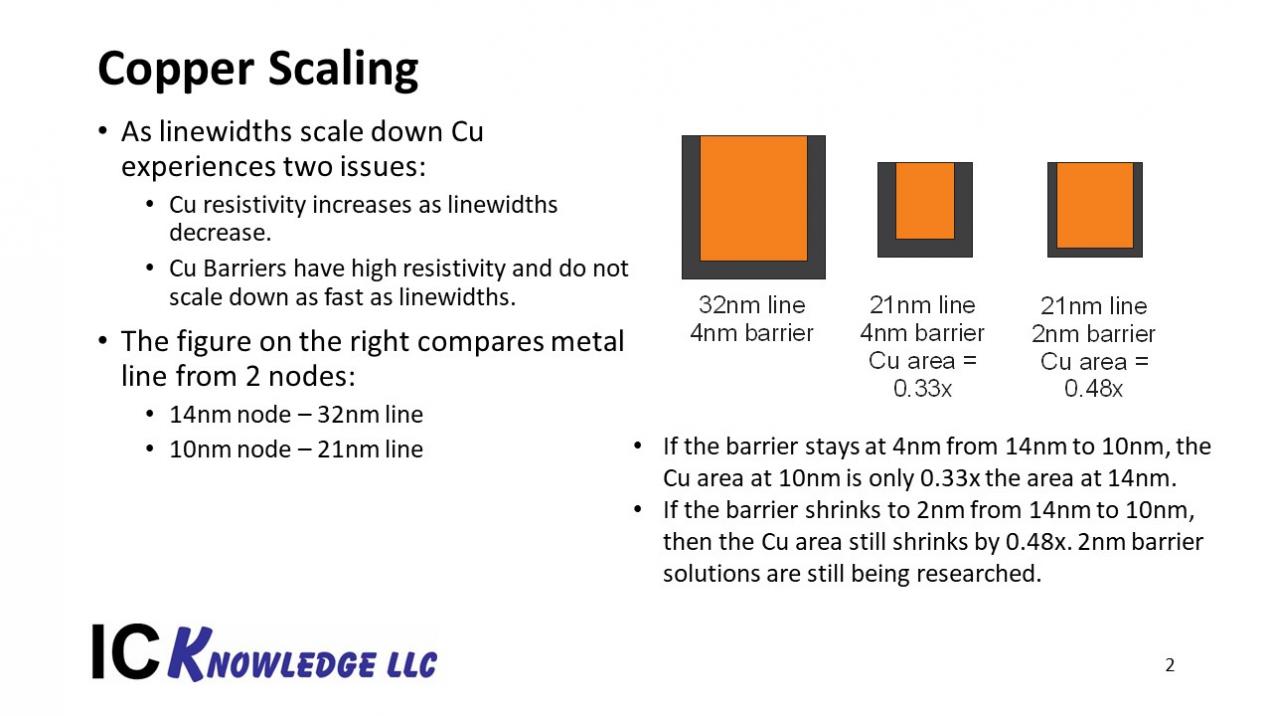

How Far Will Copper Interconnects Scale How combining cobalt and copper could improve chip yields, boost performance. applied materials has found a new way to scale interconnects to smaller process geometries without compromising their. Enabling resistance and capacitance scaling are key to delivering interconnect performance for future technology nodes [1]. copper interconnects become less advantageous at smaller dimensions due to the large mean free path of copper and the need for a diffusion barrier. in addition, electromigration (em) limits the current density of copper interconnects at small dimensions [2]. novel. Copper interconnects. in semiconductor technology, copper interconnects are interconnects made of copper. they are used in silicon integrated circuits (ics) to reduce propagation delays and power consumption. since copper is a better conductor than aluminium, ics using copper for their interconnects can have interconnects with narrower. Challenges to interconnect scaling at 3nm and beyond. by mehul naik, ph.d. jun 14, 2021. the previous blog in this series, authored by my colleague mike chudzik, previewed applied’s upcoming logic master class with a focus on transistor design and the physical limitations that must be overcome to enable advanced logic scaling.

Iitc Imec Presents Copper Cobalt And Ruthenium Interconnect Results Copper interconnects. in semiconductor technology, copper interconnects are interconnects made of copper. they are used in silicon integrated circuits (ics) to reduce propagation delays and power consumption. since copper is a better conductor than aluminium, ics using copper for their interconnects can have interconnects with narrower. Challenges to interconnect scaling at 3nm and beyond. by mehul naik, ph.d. jun 14, 2021. the previous blog in this series, authored by my colleague mike chudzik, previewed applied’s upcoming logic master class with a focus on transistor design and the physical limitations that must be overcome to enable advanced logic scaling. The size of transistors has drastically reduced over the years. interconnects have likewise also been scaled down. today, conventional copper (cu) based interconnects face a significant impediment to further scaling since their electrical conductivity decreases at smaller dimensions, which also worsens the signal delay and energy consumption. as a result, alternative scalable materials such as. Interconnect materials. for decades, aluminum interconnects were the industry standard. to create these interconnects, a layer of aluminum was deposited. then, the metal was patterned and etched, and insulating material was deposited to separate the conducting lines. in the late 1990s, chipmakers switched to copper, which conducts electricity.

Comments are closed.