How The Lifters Release Undercut Of Plastic Injection Molded Parts

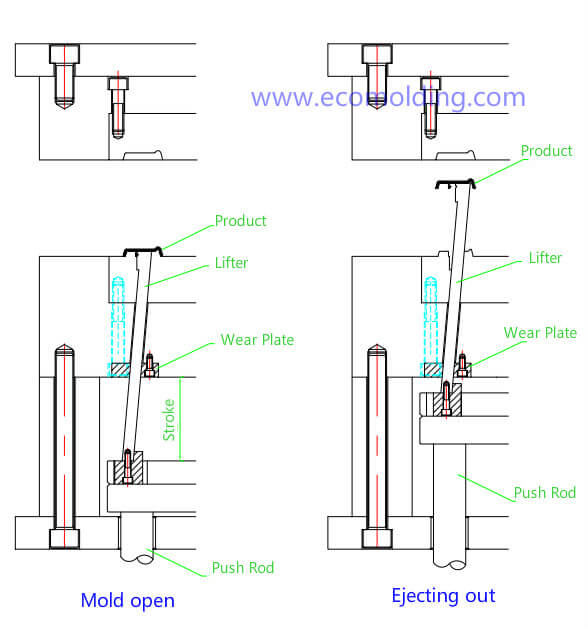

How The Lifters Release Undercut Of Plastic Injection Molded Parts Copyright reserved by: ecomolding the lifter in plastic injection mold is mainly used to form the internal undercuts of a molded plastic part. 3. bumpoffs. bumpoffs are an easy way to mold lens covers, container caps, and similar parts with functions that call for them to snap into place. rather than use a side action cam, an insert is machined so the undercut can be applied and is bolted into the mold where a pocket matches the insert dimensions.

The Lifter Design Standard For Plastic Injection Mold Tooling Faq. injection molding is a widely used manufacturing process for producing parts in large volumes. to ensure the success of injection molding, various components, such as mold lifters, play a crucial role. mold lifters are mechanisms used to create undercuts or complex features in molded parts by enabling the removal of the part from the mold. Progressive's unilifters® system is the most widely used, standard product for molding and releasing undercuts. smooth performance is attained due to the u c. These mechanisms help release the molded part by allowing certain mold components to move, creating the necessary clearance for the part to be ejected successfully. managing undercuts is an important aspect of designing injection molds to ensure efficient production and part release. 💪 💪. #undercuts #injectionmold #toolingsolutions. Step 1: analyze the part design. the first step in designing a lifter for injection molding is to analyze the part design. the design engineer must understand the part geometry, including any undercuts or other features that may require a lifter. the engineer needs to consider the complexity of the part design and the tolerances required.

Undercuts In Plastic Injection Mold And Their Solutions These mechanisms help release the molded part by allowing certain mold components to move, creating the necessary clearance for the part to be ejected successfully. managing undercuts is an important aspect of designing injection molds to ensure efficient production and part release. 💪 💪. #undercuts #injectionmold #toolingsolutions. Step 1: analyze the part design. the first step in designing a lifter for injection molding is to analyze the part design. the design engineer must understand the part geometry, including any undercuts or other features that may require a lifter. the engineer needs to consider the complexity of the part design and the tolerances required. Injection molding is the key. lifter design is crucial in this process. it's essential for creating intricate shapes and undercuts in molded parts. in this post, you'll learn about the importance of lifter design, its benefits, and how it enhances manufacturing efficiency. this article is perfect for engineers, designers, and anyone interested. A lifter is a mechanism that is often used in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of the molded part from the mold.

Comments are closed.