How To Properly Test Five Star Epoxy Grouts For Compressive Strength According To Astm C579 B

How To Properly Test Five Star Epoxy Grouts For Compressiveођ @fivestarproductsinc epoxy grouts should be tested for compressive strength using 2” cube specimens made in brass or steel cube molds as directed in astm c. Compressive strength. five star® epoxy grouts should be tested for compressive strength using 2” x 2” cube specimens made in brass or steel cube molds and a cover plate as directed in astm c 579, method b. the use of cover plates on cube molds ensures more accurate testing and is highly recommended. the use of cylinders, plastic molds, or.

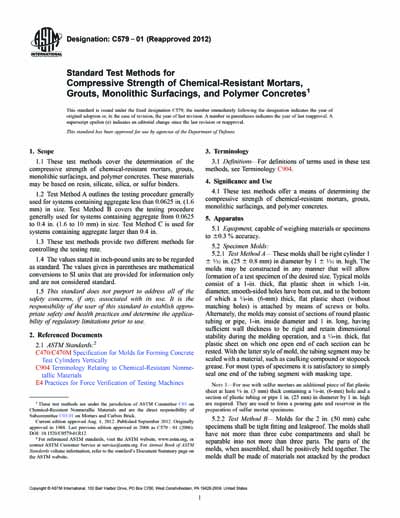

Astm C579 01 2012 Standard Test Methods For Compressive Strength Of Significance and use 4.1 these test methods offer a means of determining the compressive strength of chemical resistant mortars, grouts, monolithic surfacings, and polymer concretes.scope 1.1 these test methods cover the determination of the compressive s. 1.2 test method a outlines the testing procedure generally used for systems containing aggregate less than 0.0625 in. (1.6 mm) in size. test method b covers the testing procedure generally used for systems containing aggregate from 0.0625 to 0.4 in. (1.6 to 10 mm) in size. test method c is used for systems containing aggregate larger than 0.4 in. Astm c579 18 redline astm c579 18. designation: c579−01 (reapproved 2012)c579 18. standard test methods for. compressive strength of chemical resistant mortars, grouts, monolithic surfacings, and polymer concretes1. this standard is issued under the fixed designation c579; the number immediately following the designation indicates the year. Astm c579 outlines standard procedures for determining the compressive strength of various chemical resistant materials, including mortars, grouts, monolithic surfacings, and polymer concretes. this test is crucial for assessing the durability and performance of these materials in harsh environments exposed to chemicals. key aspects of the test.

Astm C579 23 Red Standard Test Methods For Compressive Strength Of Astm c579 18 redline astm c579 18. designation: c579−01 (reapproved 2012)c579 18. standard test methods for. compressive strength of chemical resistant mortars, grouts, monolithic surfacings, and polymer concretes1. this standard is issued under the fixed designation c579; the number immediately following the designation indicates the year. Astm c579 outlines standard procedures for determining the compressive strength of various chemical resistant materials, including mortars, grouts, monolithic surfacings, and polymer concretes. this test is crucial for assessing the durability and performance of these materials in harsh environments exposed to chemicals. key aspects of the test. 1.1 these test methods cover the determination of the compressive strength of chemical resistant mortars, grouts, monolithic surfacings, and polymer concretes. these materials may be based on resin, silicate, silica, or sulfur binders. Test method b covers the testing procedure generally used for systems containing aggregate from 0.0625 to 0.4 in. (1.6 to 10 mm) in size. test method c is used for systems containing aggregate larger than 0.4 in. 1.3 these test methods provide two different methods for controlling the testing rate.

Understanding Flooring Performance Data To Optimize Specifications 1.1 these test methods cover the determination of the compressive strength of chemical resistant mortars, grouts, monolithic surfacings, and polymer concretes. these materials may be based on resin, silicate, silica, or sulfur binders. Test method b covers the testing procedure generally used for systems containing aggregate from 0.0625 to 0.4 in. (1.6 to 10 mm) in size. test method c is used for systems containing aggregate larger than 0.4 in. 1.3 these test methods provide two different methods for controlling the testing rate.

Comments are closed.