How To Use Undercuts In Plastic Injection Molding Xcentric Mold

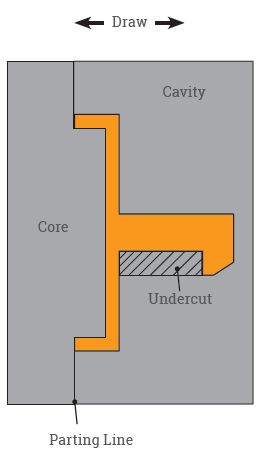

How To Use Undercuts In Plastic Injection Molding Xcentric Mold Purpose of undercuts in plastic injection molding. some of the more common ways to use undercuts: create interlocking or snap and latch features. this allows for clamshell or housing designs to come together for quick and easy assembly; capture side holes or ports for wiring,and button features; capture vertical threads and barb fittings. barb. An undercut in injection molding is any part feature that prohibits an ejection of a part from the mold. watch the video demonstration for more information. reducing the number of undercuts will reduce the cost of tooling. at xcentric we have the capability of producing your custom injection molded parts with any number of undercuts.

How To Use Undercuts In Plastic Injection Molding Xcentric Mold 3. bumpoffs. bumpoffs are an easy way to mold lens covers, container caps, and similar parts with functions that call for them to snap into place. rather than use a side action cam, an insert is machined so the undercut can be applied and is bolted into the mold where a pocket matches the insert dimensions. By following the above stated best practices, it is possible to control undercuts in injection molding and improve the quality of products and manufacturing processes. common challenges of injection molding undercuts and their solutions: injection molding undercuts pose several problems, although their solutions can be implemented as described. Draft angles of 1.5° to 2° per side are standard for plastic injection molding. for surfaces that will be textured, a 3° – 5° draft angle is required. runners and gates. runners and gates must be designed and incorporated into a mold to ensure that a consistent flow of material fills the mold at the right pressure. Learn what an undercut in injection molding is and how to design your part avoiding undercuts. we'll demonstrate how to re design a part with an undercut in.

Comments are closed.