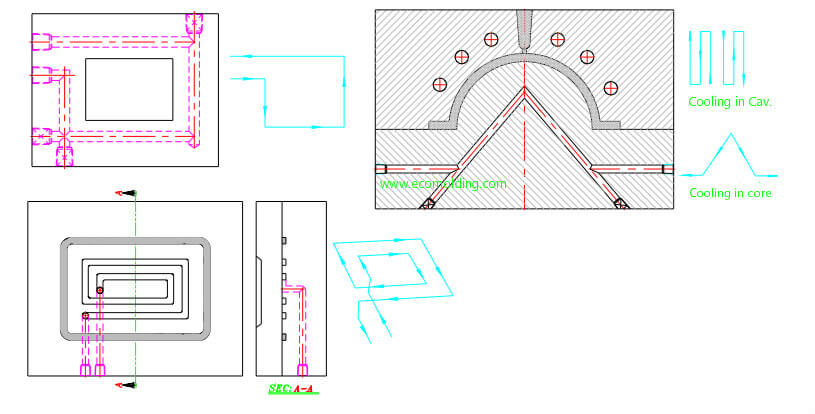

Injection Mold Cooling Channel Diagram

Mesh Sections Of The Injection Mold Conformal Cooling Channels And The goal when locating cooling channels in the mold is uniform mold surface temperature, which is determined by cooling channel depth and pitch. consider the following examples of cooling channel configurations in p20 mold steel with a water line diameter (d) of 11.1mm (7 16"), coolant temperature of 30ºc and cycle time of 17 seconds (see fig. 3). Depending on the flow resistance of each individual cooling channel. this varying of the flow rate, in turn, causes the heat transfer effi ciency of the cooling cha nnels to vary from one to another. as a result, cooling of the mold may not be uniform with a parallel cooling channel configuration. 2.2.2 serial cooling channels.

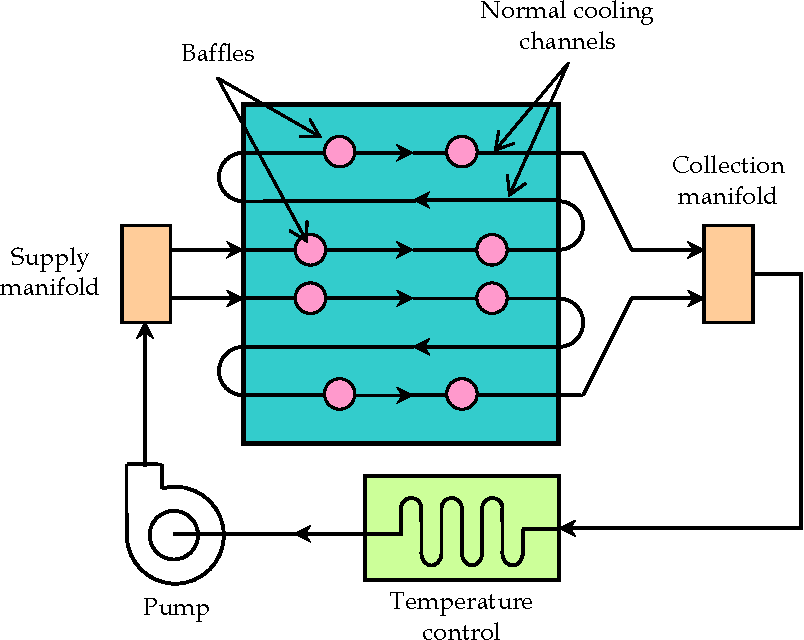

Cooling Channel Configuration China Injection Mold China Mould Maker To enhance the efficiency of the cooling system and ensure uniform temperature distribution across the mold cavity, the following principles should be adhered to: 1. optimal cooling method and circuit placement: during mold design, prioritize the cooling method and circuit placement, ensuring sufficient space for turbulent water flow in the. Here’s the scoop: after the molten plastic is injected into the mold cavity, it needs to cool and solidify into the desired shape. it’s during this phase that the cooling system comes into play. comprising cooling channels, through which a coolant flows, the system efficiently draws heat away from the molded part. 10 | cooling of an injection mold after 10 minutes of cooling, the temperature in the mold block is more uniform, with a temperature at the center of approximately 333 k ( figure 7). still, the faces with cooling channel inlets and outlets are more than 20 k hotter. figure 7: temperature distribution in the steel mold block after 10 minutes of. The study considered optimization cooling channel of injection mold. cooling channel was used to heating up the mold surface temperature instead of added external component such as air heating [3, 4, 5], heating resistance [6], infrared, …. during the injection process, melted plastic was filled into the empty space between cavity and core.

Injection Mold Cooling System Design Moldchina 10 | cooling of an injection mold after 10 minutes of cooling, the temperature in the mold block is more uniform, with a temperature at the center of approximately 333 k ( figure 7). still, the faces with cooling channel inlets and outlets are more than 20 k hotter. figure 7: temperature distribution in the steel mold block after 10 minutes of. The study considered optimization cooling channel of injection mold. cooling channel was used to heating up the mold surface temperature instead of added external component such as air heating [3, 4, 5], heating resistance [6], infrared, …. during the injection process, melted plastic was filled into the empty space between cavity and core. Optimizing the design of the conformal cooling channel can increase the cooling rate of injection mold. the aim of this study was the problem of low cooling efficiency of injection mold for deep cavity plastic parts under the conventional cooling channel. based on the analysis of the heat transfer principle of the injection mold, a mathematical description of the cooling time of the conformal. With the help of the spatial balanced coverage feature of the spatial voronoi diagram, the spatial voronoi diagram is generated on the offset surface of the mold cavity, and the conformal cooling channel of the part can be obtained by sweeping the spatial voronoi diagram . however, this method generates too many channel grids, complex channels.

Injection Mold Cooling Systems Design Types And Channel Layout Optimizing the design of the conformal cooling channel can increase the cooling rate of injection mold. the aim of this study was the problem of low cooling efficiency of injection mold for deep cavity plastic parts under the conventional cooling channel. based on the analysis of the heat transfer principle of the injection mold, a mathematical description of the cooling time of the conformal. With the help of the spatial balanced coverage feature of the spatial voronoi diagram, the spatial voronoi diagram is generated on the offset surface of the mold cavity, and the conformal cooling channel of the part can be obtained by sweeping the spatial voronoi diagram . however, this method generates too many channel grids, complex channels.

Figure 2 From Design And Simulation Based Optimization Of Cooling

Comments are closed.