Injection Mold Slide And Lifter Design Manufacturing Guidance Upmold

Injection Mold Slide And Lifter Design Manufacturing Guidance Upmold Injection mold slide and lifter design & manufacturing guidance section 2: slides lifters standards and design contents: a) mechanical injecion mold slide design standards b) hydraulic injecion mold slide design standards b) injection mold lifter standard a) mechanical injecion mold slide design standards (refer to drawing s2 1 & s2 2): 1) all. Injection molding mold design tutorial section 1: injection mold design the following information defines the minimum requirements for upmold injection molds produced by upmold engineering. alternatives that will contribute to improved tool life, minimum wear, ease of molding, and ease of manufacturing will be considered within the confines of.

Injection Mold Slide And Lifter Design Guideline Injection A lifter is a mechanism used in the design and manufacturing of molds, typically in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of. Of course, slide and lifter will be used on mold that is best solution for undercut, but that will be marked on part after molding, so we need to discuss with our customer that what is the best location for split. A lifter is a mechanism that is often used in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of the molded part from the mold. Step 1: identify the needed support. it is essential to identify the sections of the lifter that require support. this may include where the lifter may face high stress or force and additional support is needed. by putting these into account the type and amount of support required is determined.

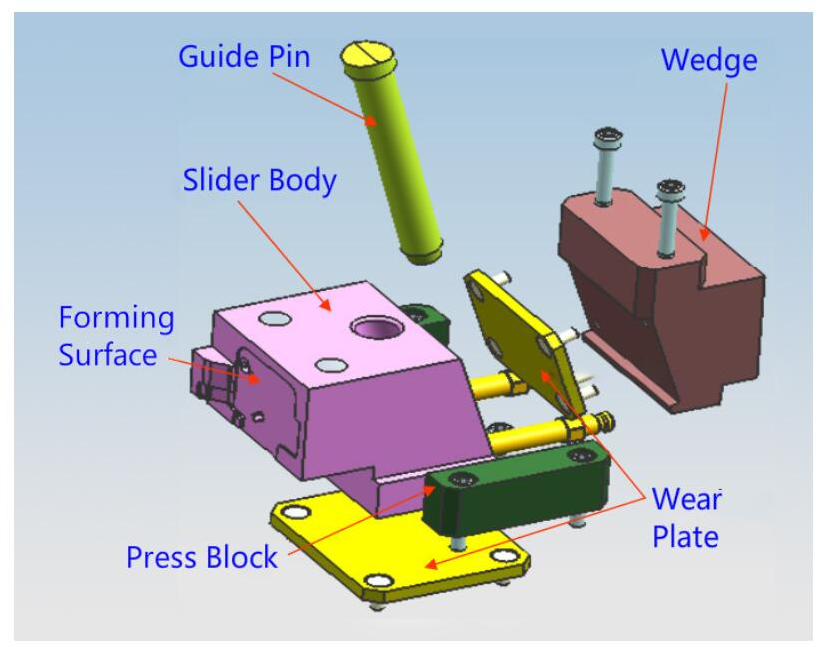

Injection Mold Slider Design A lifter is a mechanism that is often used in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of the molded part from the mold. Step 1: identify the needed support. it is essential to identify the sections of the lifter that require support. this may include where the lifter may face high stress or force and additional support is needed. by putting these into account the type and amount of support required is determined. Step 1: analyze the part design. the first step in designing a lifter for injection molding is to analyze the part design. the design engineer must understand the part geometry, including any undercuts or other features that may require a lifter. the engineer needs to consider the complexity of the part design and the tolerances required. Injection molding is the key. lifter design is crucial in this process. it's essential for creating intricate shapes and undercuts in molded parts. in this post, you'll learn about the importance of lifter design, its benefits, and how it enhances manufacturing efficiency. this article is perfect for engineers, designers, and anyone interested.

Comments are closed.