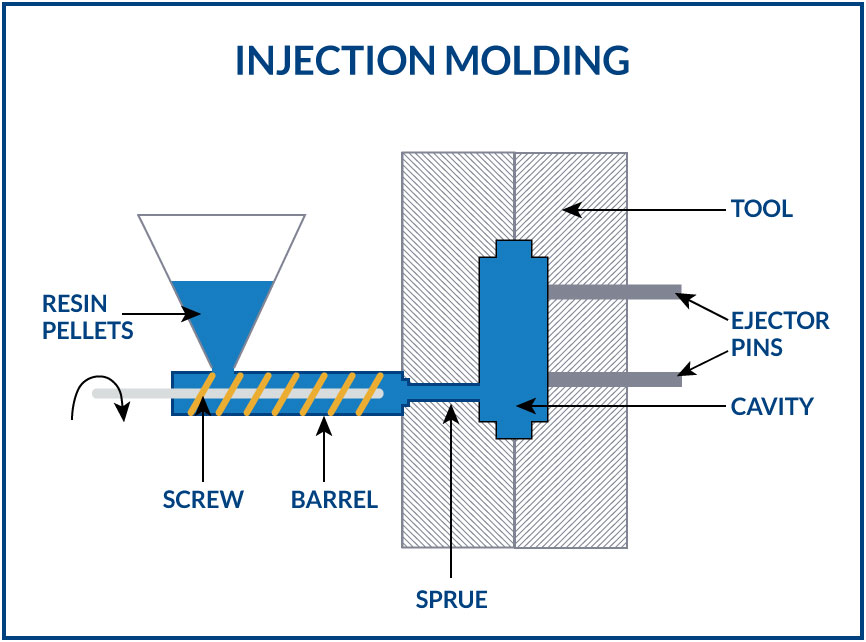

Injection Molding Process Diagram

Injection Molding Step By Step How Are Plastic Parts Made Injection molding injection molding is an established manufacturing technology with a long history, but it is constantly being refined and improved with new technological advancements. below is a quick rundown of the key advantages and disad vantages of injection molding to help you understand whether it is the right solution for your application. To provide a detailed insight into the injection moulding process, we will use the iol (intraocular lens) cartridge as a case study, illustrating each injection moulding process step by step. step 1: plasticizing. in this phase, medical grade plastic pellets, namely polypropylene (pp), are employed in the production of cartridges, which are.

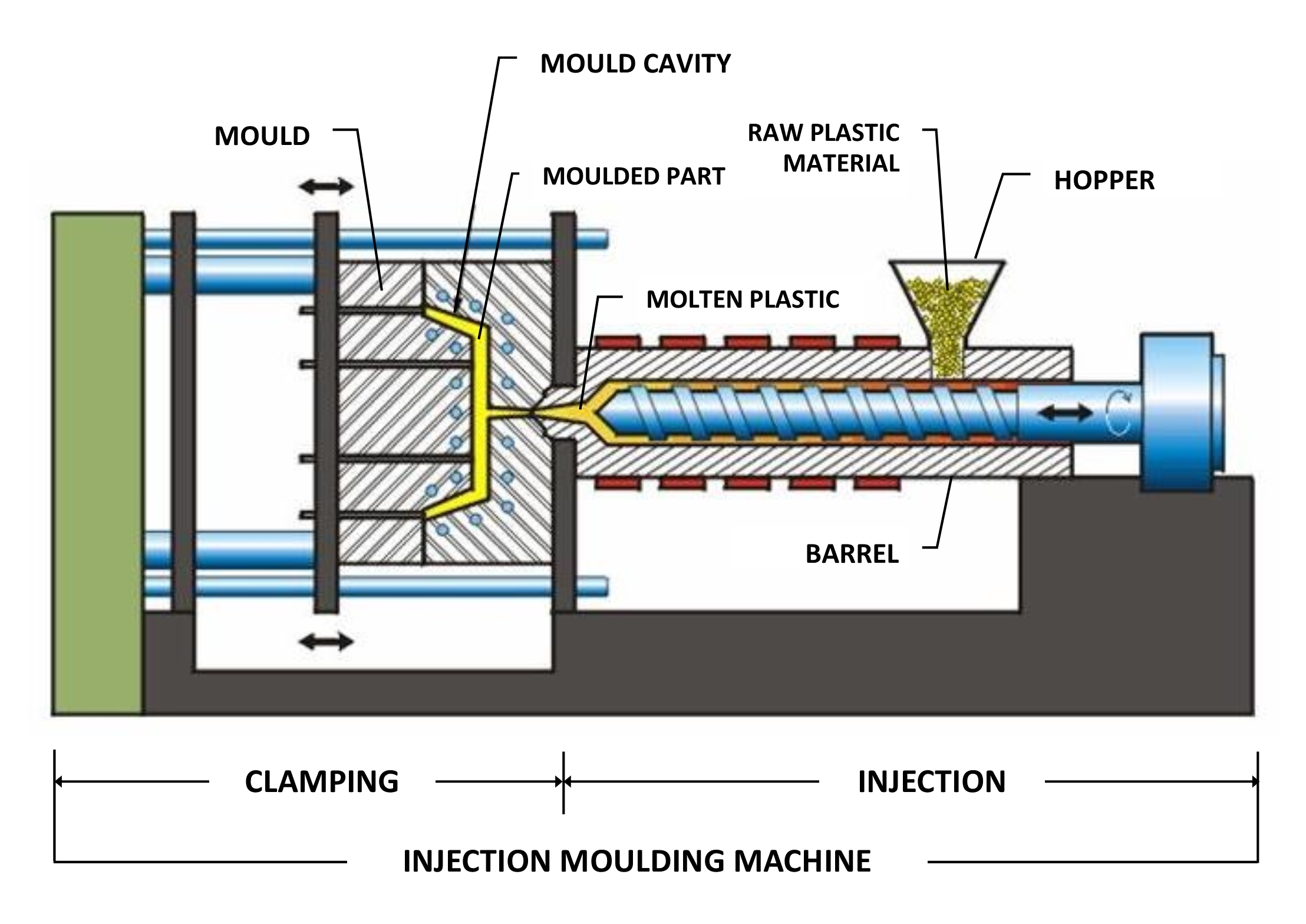

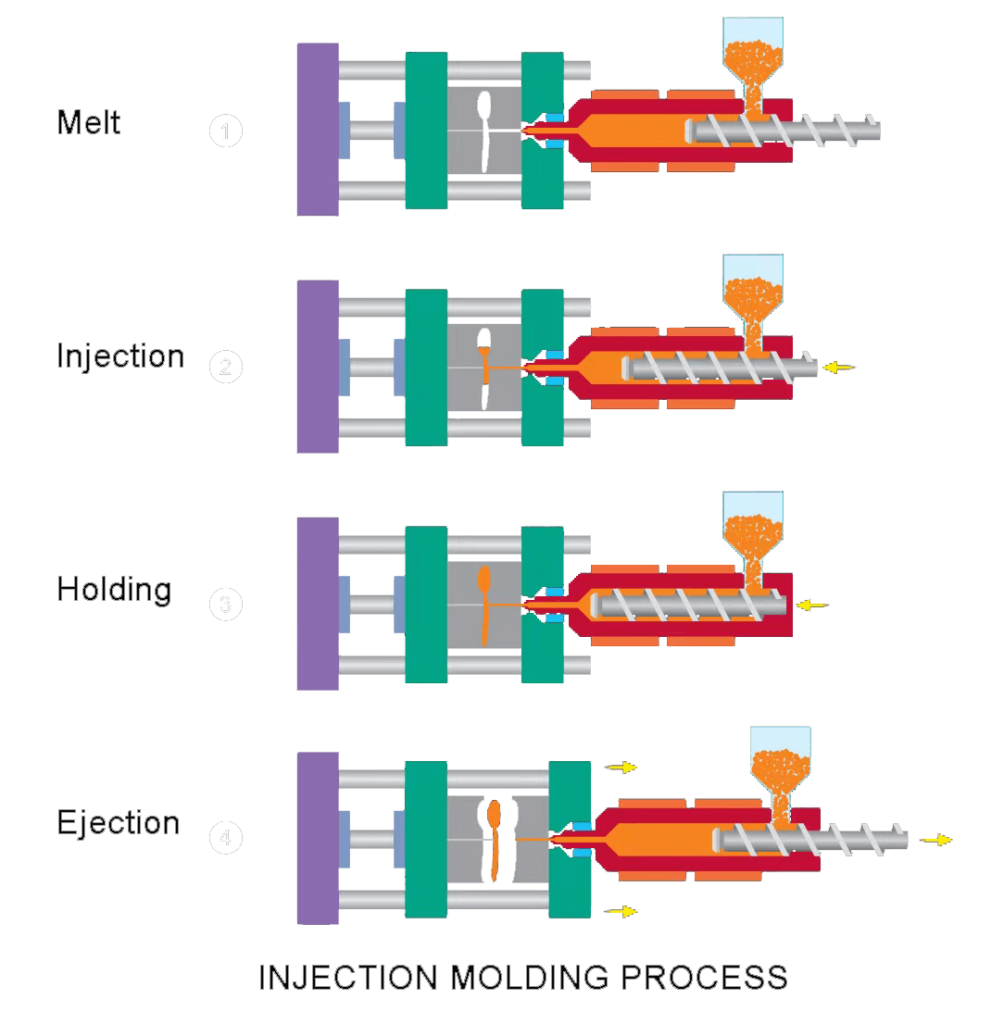

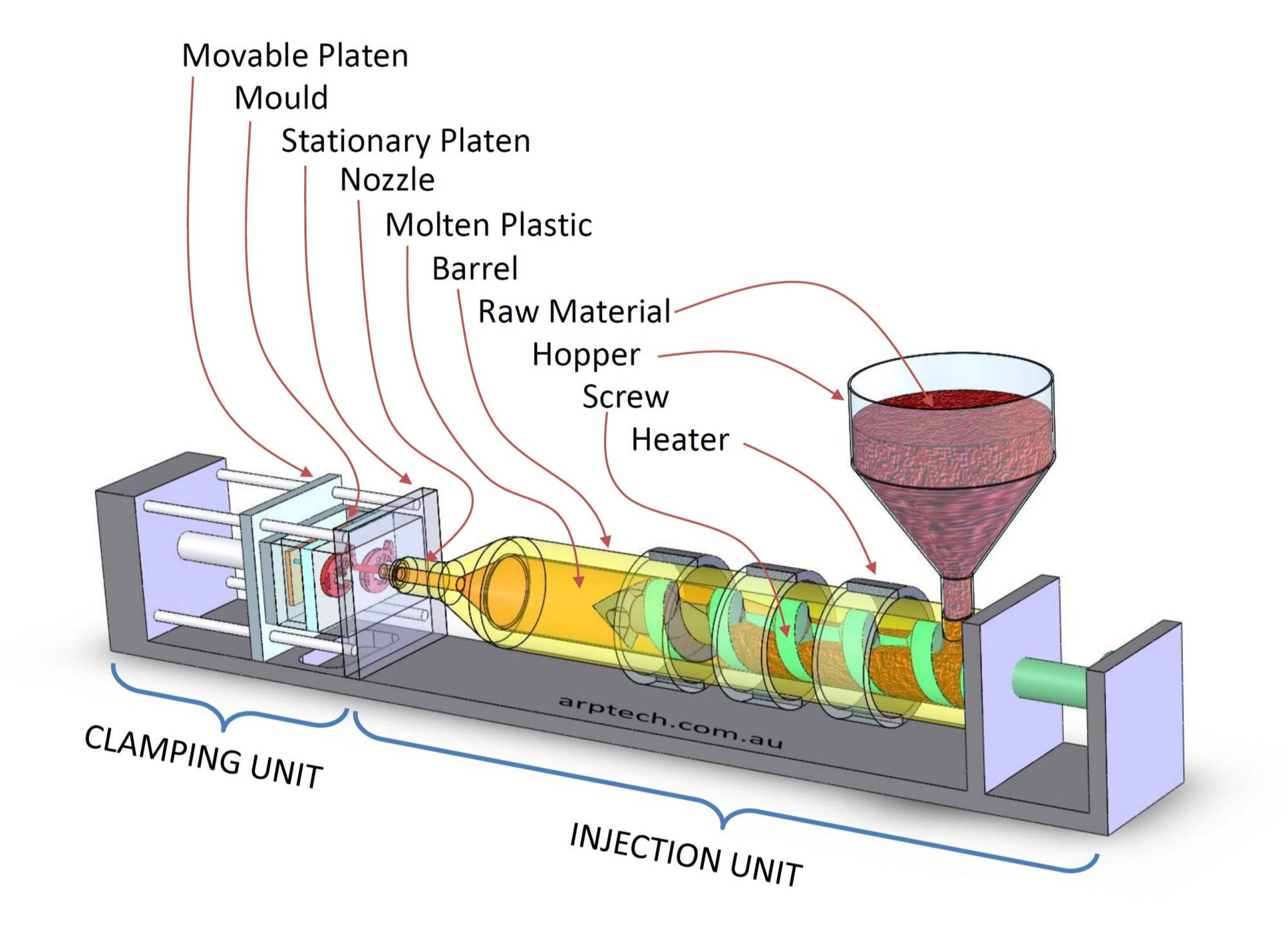

Robotics In Injection Moulding Rna Automation The injection molding process. the injection molding process can be divided into several stages: clamping: the mold is securely closed and held in place by a clamping unit. this ensures that the mold remains closed during the injection and cooling phases. injection: the molten material is injected into the mold cavity under high pressure. the. The injection moulding cycle – working. injection molding diagram. there are three main stages in the injection moulding cycle; stage 1, injection, followed by stage 2, holding pressure and plasticating, and finally, stage 3, ejection of the moulded part. when stage 3 is completed, the mould closes again and the cycle starts over again. Anything from electronics enclosures to medical supplies starts as injection molded parts. the injection molding process step by step. while seemingly simple, injection molding requires careful control across four main phases: clamping – a hydraulic press secures the two mold halves together. this prevents material from leaking during. The injection moulding process is a manufacturing process used for producing parts or components by injecting molten material into the mold cavity. injection molding can be performed with only one of these materials like glass, plastics, etc. and most commonly, thermoplastic polymers are used.

3 Basic Steps Of The Injection Molding Process 2020 Anything from electronics enclosures to medical supplies starts as injection molded parts. the injection molding process step by step. while seemingly simple, injection molding requires careful control across four main phases: clamping – a hydraulic press secures the two mold halves together. this prevents material from leaking during. The injection moulding process is a manufacturing process used for producing parts or components by injecting molten material into the mold cavity. injection molding can be performed with only one of these materials like glass, plastics, etc. and most commonly, thermoplastic polymers are used. Assuming that the mold has already been created, injection molding becomes an easily repeatable process consisting of six discrete steps: 1. clamping. the first step of the injection molding process is clamping. injection molds are typically made in two, clamshell style pieces. in the clamping phase, the two metal plates of the mold are pushed. Step 6: ejection of the part. with the cooling process complete, it’s time for the birth of a new component. the clamping unit of the injection moulding machine opens, and the newly formed part is ejected from the mold. this is done using ejector pins which push the part out of the mold.

Injection Molding Process Topworks Plastic Molding Assuming that the mold has already been created, injection molding becomes an easily repeatable process consisting of six discrete steps: 1. clamping. the first step of the injection molding process is clamping. injection molds are typically made in two, clamshell style pieces. in the clamping phase, the two metal plates of the mold are pushed. Step 6: ejection of the part. with the cooling process complete, it’s time for the birth of a new component. the clamping unit of the injection moulding machine opens, and the newly formed part is ejected from the mold. this is done using ejector pins which push the part out of the mold.

Injection Moulding Process Explained Arptech Blog

Comments are closed.