Injection Molding Step By Step How Are Plastic Parts Made

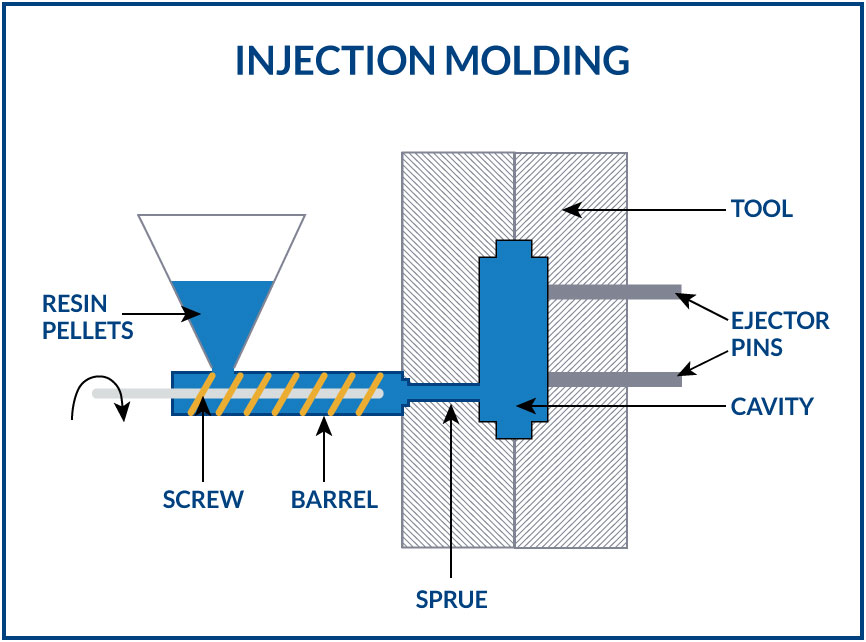

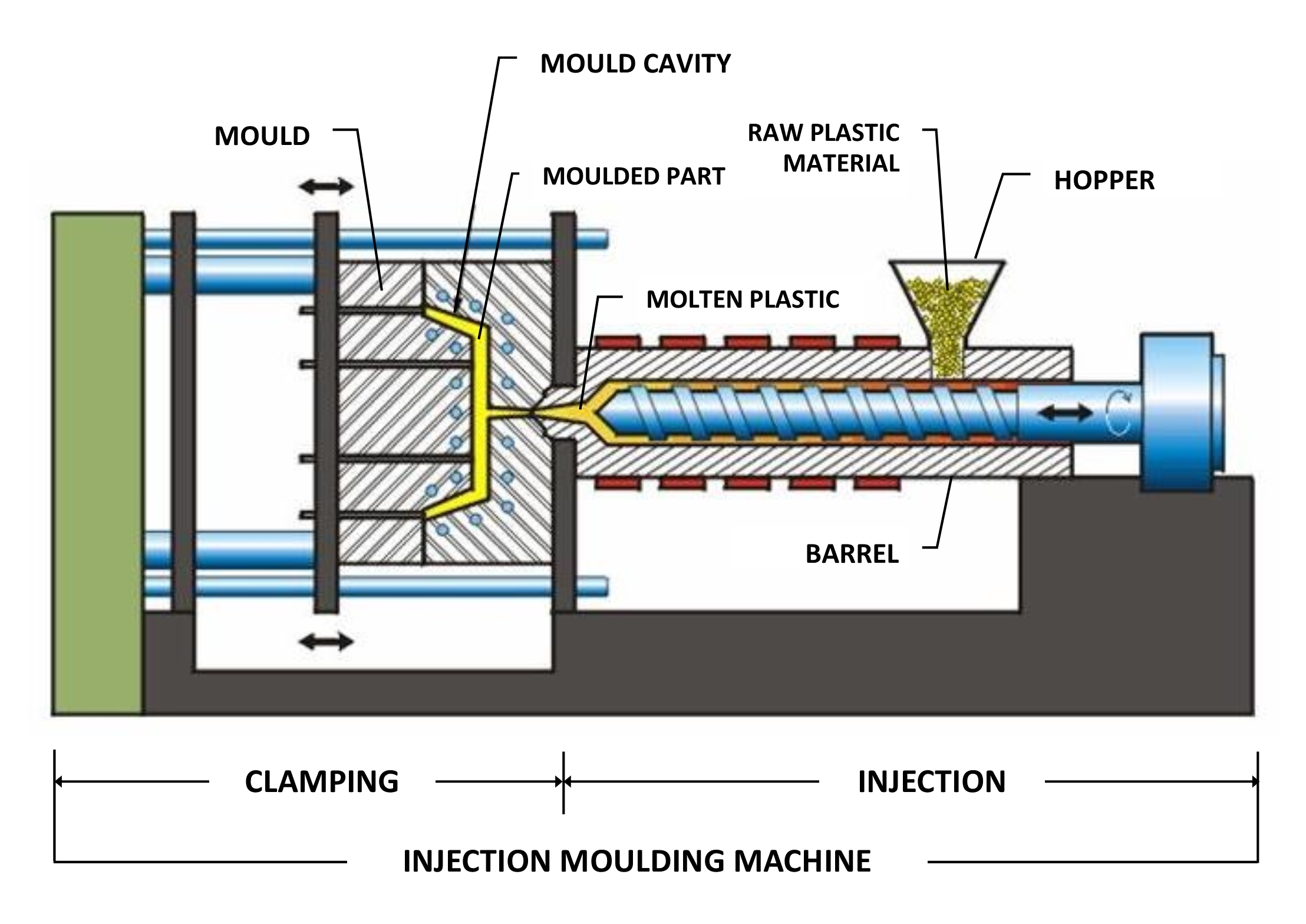

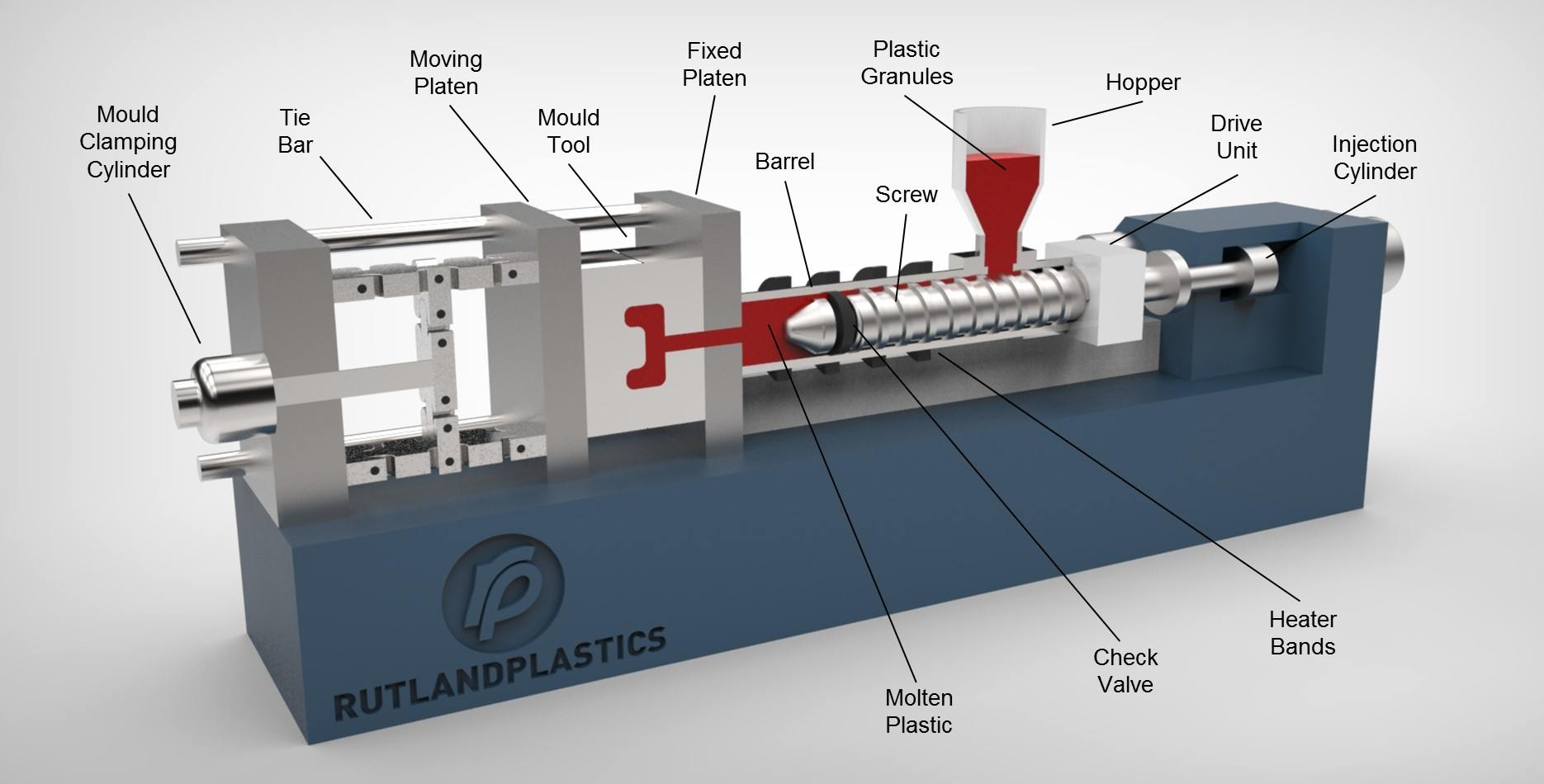

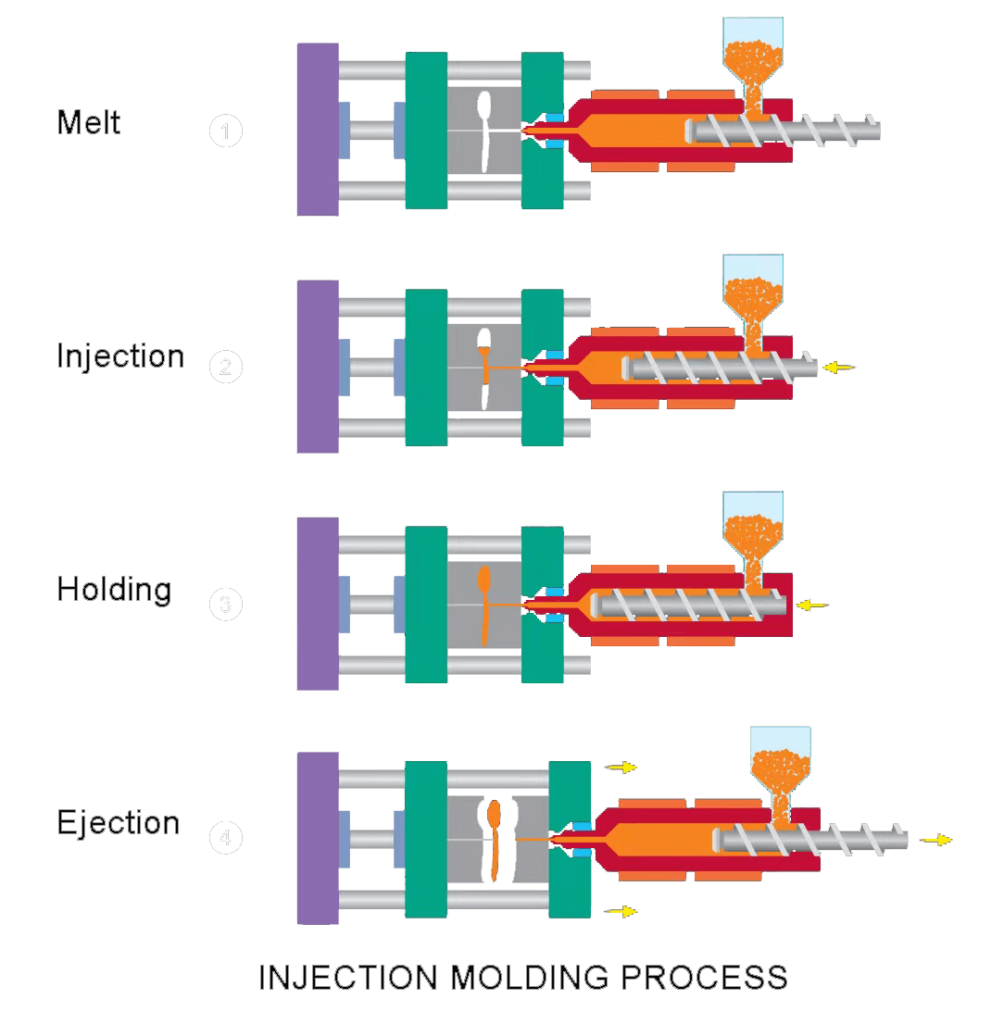

Injection Molding Step By Step How Are Plastic Parts Made Injection molding process. clamping: the mold is mounted onto the injection molding machine. the two halves are securely closed using hydraulic or mechanical force to ensure proper alignment. injection: plastic pellets, known as resin, are fed into the injection molding machine’s hopper. the pellets are heated and melted within the barrel to. Heaters within the barrel screw keep the melt plasticized at its designated temperature. once the molded material reaches its ideal ejection temperature, the tool opens and the part is pushed out by the forward motion of the ejector rod and pins. the part can be extracted by a robot, manual operator, or falls freely into a bin underneath the tool.

Robotics In Injection Moulding Rna Automation It involves several essential steps: 1. design and prototyping: plastic injection molding. the process begins with the design of the part and the creation of a prototype. designers use cad software to create a 3d model of the component, which is then used to generate a mold. 2. At this time, it is necessary to adjust the parameters of the injection moulding machine according to the conditions of plastic injection moulding, to avoid subsequent issues, such as non conforming dimensions and burrs etc. step 3: holding pressure. at this stage, the molten plastic thoroughly fills the entire mould. 5 steps of the plastic mold injection process. to create high quality parts with consistency and efficiency, manufacturers must follow the following injection molding steps, from mold design to cooling and ejection. step 1: mold design and creation. this initial step is critical as it shapes the entire plastic injection molding process. Anything from electronics enclosures to medical supplies starts as injection molded parts. the injection molding process step by step. while seemingly simple, injection molding requires careful control across four main phases: clamping – a hydraulic press secures the two mold halves together. this prevents material from leaking during.

How Does Injection Moulding Work Rutland Plastics 5 steps of the plastic mold injection process. to create high quality parts with consistency and efficiency, manufacturers must follow the following injection molding steps, from mold design to cooling and ejection. step 1: mold design and creation. this initial step is critical as it shapes the entire plastic injection molding process. Anything from electronics enclosures to medical supplies starts as injection molded parts. the injection molding process step by step. while seemingly simple, injection molding requires careful control across four main phases: clamping – a hydraulic press secures the two mold halves together. this prevents material from leaking during. Plastic injection molding projects can take anywhere from two to six weeks, depending on the complexity of the mold design, the type of plastic material used, and the total quantity of parts required. simpler projects may take just a few weeks, while those requiring unique materials or detailed specifications can take up to six weeks. Injection molding is a fascinating process used in the manufacturing of plastic parts, from small components to large panels. it involves melting plastic pellets, injecting the molten plastic into a mold, cooling it to solidify into the desired shape, and finally ejecting the finished part. this process is favored for its precision, efficiency.

Injection Molding Step By Step How Are Plastic Parts Made Plastic injection molding projects can take anywhere from two to six weeks, depending on the complexity of the mold design, the type of plastic material used, and the total quantity of parts required. simpler projects may take just a few weeks, while those requiring unique materials or detailed specifications can take up to six weeks. Injection molding is a fascinating process used in the manufacturing of plastic parts, from small components to large panels. it involves melting plastic pellets, injecting the molten plastic into a mold, cooling it to solidify into the desired shape, and finally ejecting the finished part. this process is favored for its precision, efficiency.

Injection Molding Process Topworks Plastic Molding

Comments are closed.