Iso Fits And Tolerances Chart Pasays

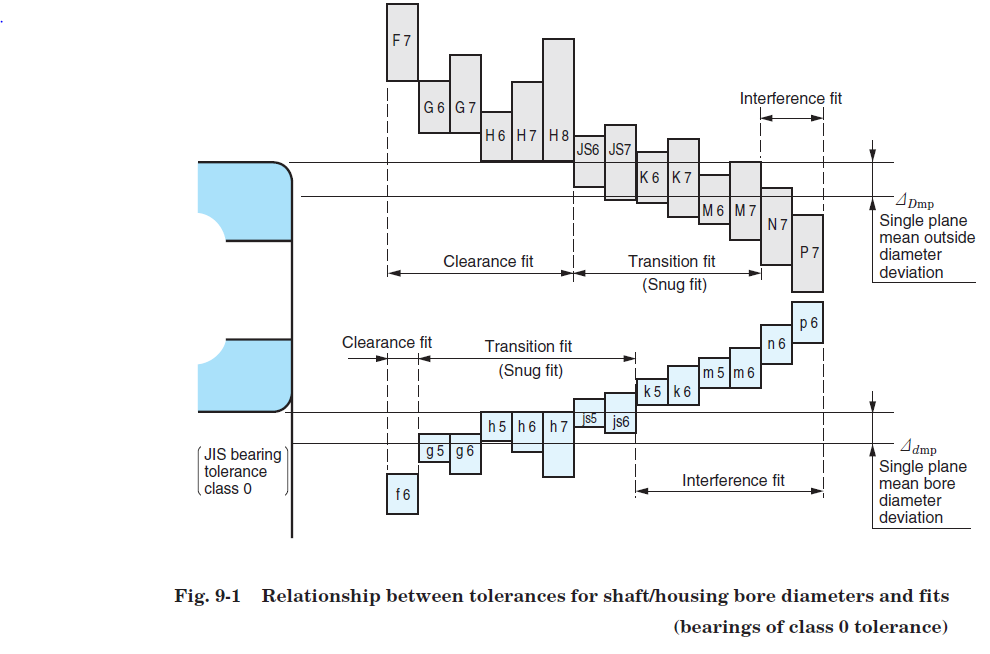

Iso Fits And Tolerances Chart Pasays Engineering tolerances. the most commonly used tolerancing system for shafts and holes is detailed in iso 286 1 & 286 2. the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be calculated. Preferred fits and tolerances charts (iso & ansi metric standards) preferred fits and tolerance table for hole and shaft basis systems which are given in iso 286 1 (2010) and ansi b4.2 1978 standards. the usage of these tolerances is advised for economic reasons. loose running fit for wide commercial tolerances or allowances on external members.

Iso Fits And Tolerances Chart Pasays H11 c11. loose running: fit for wide commercial tolerances. h9 e9. free running: good for large temperature variations, high running speeds. h8 f7. close running: for accurate location and moderate speeds. h7 g6. sliding fit: not intended to run freely, but to move and turn and locate accurately. h7 h6. The iso system of limits and fits is a coordinated system of hole and shaft tolerances for engineering and manufacturing used for cutting tools, material stock, gages, etc. if held to these tolerances, cutting tools, material stock, and gages are generally available throughout the world. the hole basis fits have four preferred hole tolerances. Fits and tolerance calculator for shaft and hole tolerance calculation according to iso 286 1 and ansi b4.2 metric standards . the schematic representation of the fit is also drawn by tolerance calculator. the tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the. Navigating tolerance charts. june 10, 2024 12:58 pm. drawings often include notations such as “25 g6” or “17.5 h11 g8” to specify tolerances. these are called “engineering fits and tolerances” and are listed in long, confusing charts. navigating those tables and understanding the nuances can be intimidating, but we will clarify it.

Iso Fits And Tolerances Chart Bopqesyn Fits and tolerance calculator for shaft and hole tolerance calculation according to iso 286 1 and ansi b4.2 metric standards . the schematic representation of the fit is also drawn by tolerance calculator. the tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the. Navigating tolerance charts. june 10, 2024 12:58 pm. drawings often include notations such as “25 g6” or “17.5 h11 g8” to specify tolerances. these are called “engineering fits and tolerances” and are listed in long, confusing charts. navigating those tables and understanding the nuances can be intimidating, but we will clarify it. Basic size in milimeters. deviation in microns. green = "prefered" tolerance classes per iso 286. find your data faster with our fits and tolerance calculator. the inch values shown in the table are conversion from the mertic values per iso 286. you should expect about 0.1 0.5 thous errors wehn comparing with ansi b4.1 4.2! basic size. f3. f4. f5. Manufacturing process selection 1.70. clearance holes and tolerances for inch size fasteners. the hole sizes for inch fasteners are patterned after usa common usage and the general clearances translated from the metric standard. the hole tolerances are based on the iso system of limits and fits, as required by iso 273.

Comments are closed.