Lect 13 Cooling Curve Construction Of Phase Diagramintroduction To Crystal S

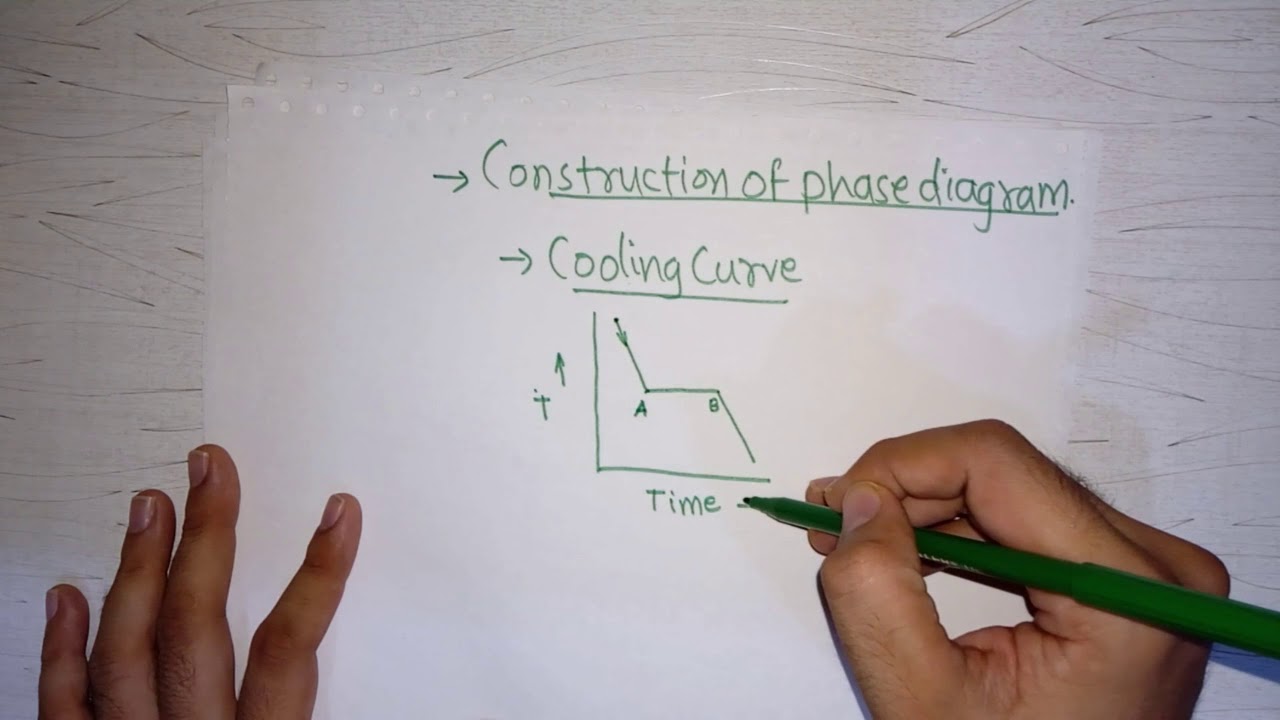

Lect 13 Cooling Curve Construction Of Phase Diagram Introduct What is cooling curve and how phase diagrams are constructed. Cooling curves and phase diagram by observin g the cooling curves of several samples of an alloy across a range of compositions, the shape of the liquidus curves and the eutectic temperature of the eutectic binary system can be determined (6.4.). cooling curves can be also used to investigate all other types of transformations.

Explain The Cooling Curve In Crystalline And Amorphous Solids The cooling curve method is one of the oldest and simplest methods to determine phase diagrams and phase transition temperatures. this is achieved by recording temperature (t) of a material versus time as it cools from its molten state through solidification (at constant pressure). whenever a phase change takes place in a metal or alloy, the. By removing the time axis from the curves and replacing it with composition, the cooling curves indicate the temperatures of the solidus and liquidus for a given composition. this allows the solidus and liquidus to be plotted to produce the phase diagram: this page titled 12.5: interpretation of cooling curves is shared under a cc by nc sa. Phase diagram and “degrees of freedom”. phase diagrams is a type of graph used to show the equilibrium conditions between the thermodynamically distinct phases; or to show what phases are present in the material system at various t, p, and compositions. “equilibrium” is important: phase diagrams are determined by using slow cooling. Interpretation of cooling curves. the melting temperature of any pure material (a one component system) at constant pressure is a single unique temperature. the liquid and solid phases exist together in equilibrium only at this temperature. when cooled, the temperature of the molten material will steadily decrease until the melting point is.

Cooling Curve Phase Diagram Phase diagram and “degrees of freedom”. phase diagrams is a type of graph used to show the equilibrium conditions between the thermodynamically distinct phases; or to show what phases are present in the material system at various t, p, and compositions. “equilibrium” is important: phase diagrams are determined by using slow cooling. Interpretation of cooling curves. the melting temperature of any pure material (a one component system) at constant pressure is a single unique temperature. the liquid and solid phases exist together in equilibrium only at this temperature. when cooled, the temperature of the molten material will steadily decrease until the melting point is. The growth of cocrystalline phases continues to expand as a key area of crystal engineering research. understanding the phase behavior of the material and controlling the crystalline form of the material from a solution based route can be aided by the construction of a ternary phase diagram for the system. a range of methods exist for this process which display a variety of costs and time to. A phase is a specific arrangement of atoms in a regular repeating array, with a defined range of atomic compositions on each symmetrically unique site in the array. 400 μm. figure 1.9: two phase microstructure of a 60 wt.% cu 40 wt.% zn brass, as used in domes tic electricity plugs.

Cooling Curves And Its Types Construction Of Phase Diagrams The growth of cocrystalline phases continues to expand as a key area of crystal engineering research. understanding the phase behavior of the material and controlling the crystalline form of the material from a solution based route can be aided by the construction of a ternary phase diagram for the system. a range of methods exist for this process which display a variety of costs and time to. A phase is a specific arrangement of atoms in a regular repeating array, with a defined range of atomic compositions on each symmetrically unique site in the array. 400 μm. figure 1.9: two phase microstructure of a 60 wt.% cu 40 wt.% zn brass, as used in domes tic electricity plugs.

Comments are closed.