Lesson 2 Hydrogen Cooled Synchronous Generator

Lesson 2 Hydrogen Cooled Synchronous Generator Youtube Synchronous generator, power system protection,methods of coolbg generators,. In the hydrogen cooling of a synchronous generator, hydrogen gas is used for cooling because hydrogen gas has excellent cooling properties. the power loss (i 2 r loss) in the form of heat loss occurs in a generator when the generator delivers power to electrical equipment. the life of the generator depends on how efficient the cooling system it.

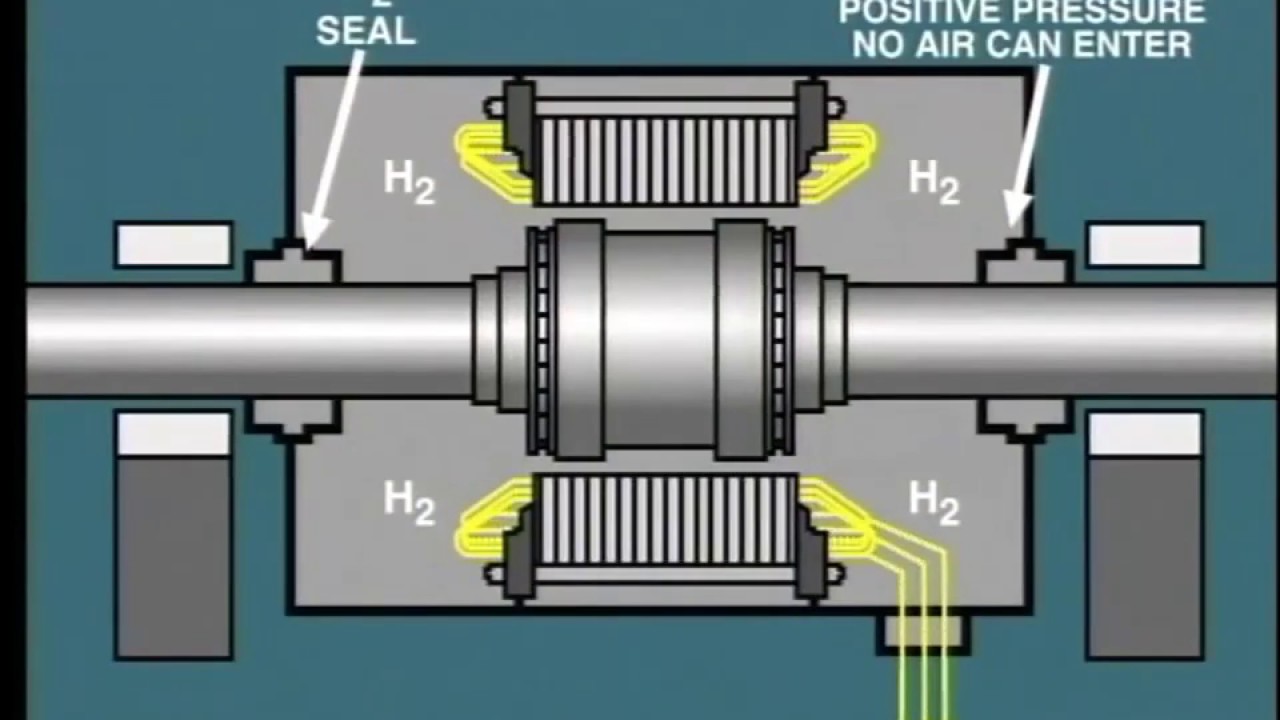

Generator Hydrogen Cooling System Youtube Limitations of hydrogen cooling. the frame of the hydrogen cooled alternator is more costly because of the necessity to provide explosion proof construction and gas tight shaft seals. means are necessary to admit hydrogen to the alternator without creating an explosion. sourcing the air with co 2 and then admitting hydrogen. Hydrogen cooling of a synchronous generator or alternator hydrogen gas is used as cooling medium for cooling the alternators because of its superior cooling properties. the hydrogen cooling of the alternators requires completely seated circulated system. mainly, oil seated glands are used between shaft and casing of the alternator. 98%. 99%. =((0.99*1) (0.01*14.4))*100. because air is 14 times as dense as hydrogen, the density of the fluid in the generator casing rises quickly with air impurity level. as can be seen from the equation, every 1 percent of air contamination is worth about 14% increase in fluid density. increased fluid density means increased windage loss. Generators used in power generation applications can be placed in three major design classifications based on the cooling medium used: air, hydrogen or liquid cooled. how well the armature winding of a generator is cooled has a significant influence on the overall size of a synchronous generator. the cooling of the armature winding is.

Hydrogen Cooling Of A Synchronous Generator 98%. 99%. =((0.99*1) (0.01*14.4))*100. because air is 14 times as dense as hydrogen, the density of the fluid in the generator casing rises quickly with air impurity level. as can be seen from the equation, every 1 percent of air contamination is worth about 14% increase in fluid density. increased fluid density means increased windage loss. Generators used in power generation applications can be placed in three major design classifications based on the cooling medium used: air, hydrogen or liquid cooled. how well the armature winding of a generator is cooled has a significant influence on the overall size of a synchronous generator. the cooling of the armature winding is. The hydrogen cooling system is uneconomical for such applications. direct water cooling is used for the synchronous generator rating 500 mw and above. in very large turbo generators, hydrogen cooling is used for the cooling of the rotor and the stator winding is cooled with direct demineralized water. the centrifugal pump circulates the water. In a hydrogen cooled system, hydrogen gas is used as a medium for cooling. a detailed explanation is given in the article hydrogen cooling of synchronous generator. direct water cooling in synchronous generator. as hydrogen cooling is not sufficient to extract heat generated in large turbo alternators of sizes 500 mw or more.

Lesson 5 Synchronous Generator Cooling Hydrogen Purging And Charging The hydrogen cooling system is uneconomical for such applications. direct water cooling is used for the synchronous generator rating 500 mw and above. in very large turbo generators, hydrogen cooling is used for the cooling of the rotor and the stator winding is cooled with direct demineralized water. the centrifugal pump circulates the water. In a hydrogen cooled system, hydrogen gas is used as a medium for cooling. a detailed explanation is given in the article hydrogen cooling of synchronous generator. direct water cooling in synchronous generator. as hydrogen cooling is not sufficient to extract heat generated in large turbo alternators of sizes 500 mw or more.

Comments are closed.