Lifter Calculation For Plastic Mold Design рџџў Automobile Injection о

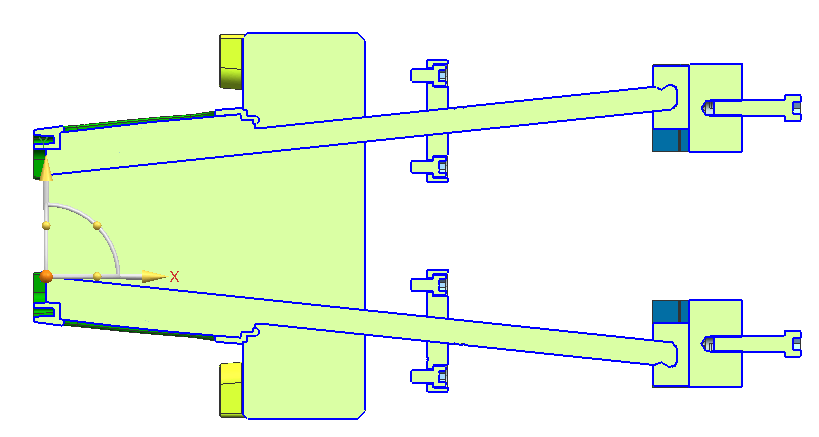

Lifter Calculation For Plastic Mold Design пёџautomobile Injectionо In this tutorials we'll discuss lifter design calculation for plastic injection mold design. here we'll calculate lifter angle & strokes. it's a single nozzl. In this tutorials we'll discuss lifter design calculation for plastic injection mold design. here we'll calculate lifter angle & strokes. it's a single nozzl.

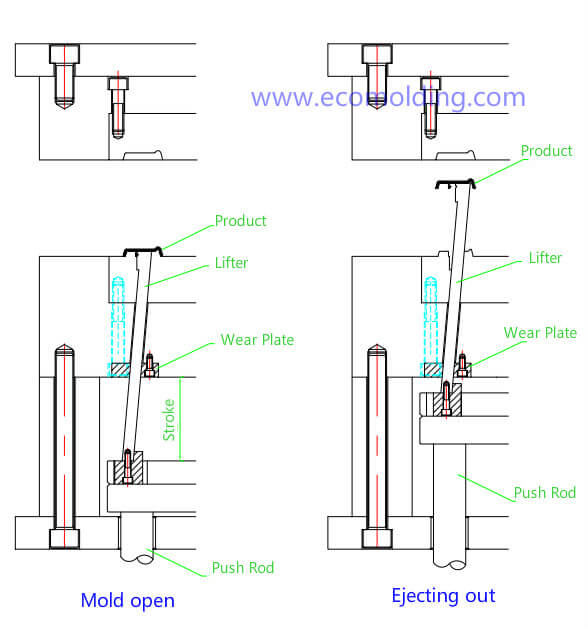

The Lifters For Plastic Injection Mold Ecomolding In this tutorials we'll discuss lifter calculations of plastic injection mold design. we'll learn how to calculate angle and stroke in lifter. for our paid o. Step 1: analyze the part design. the first step in designing a lifter for injection molding is to analyze the part design. the design engineer must understand the part geometry, including any undercuts or other features that may require a lifter. the engineer needs to consider the complexity of the part design and the tolerances required. Step 1: identify the needed support. it is essential to identify the sections of the lifter that require support. this may include where the lifter may face high stress or force and additional support is needed. by putting these into account the type and amount of support required is determined. A lifter is a mechanism used in the design and manufacturing of molds, typically in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of.

The Lifter Design Standard For Plastic Injection Mold Tooling Step 1: identify the needed support. it is essential to identify the sections of the lifter that require support. this may include where the lifter may face high stress or force and additional support is needed. by putting these into account the type and amount of support required is determined. A lifter is a mechanism used in the design and manufacturing of molds, typically in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of. Injection molding is the key. lifter design is crucial in this process. it's essential for creating intricate shapes and undercuts in molded parts. in this post, you'll learn about the importance of lifter design, its benefits, and how it enhances manufacturing efficiency. this article is perfect for engineers, designers, and anyone interested. A lifter is a mechanism that is often used in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of the molded part from the mold.

Lifter Design For Plastic Injection Mold Plastic Injection Injection molding is the key. lifter design is crucial in this process. it's essential for creating intricate shapes and undercuts in molded parts. in this post, you'll learn about the importance of lifter design, its benefits, and how it enhances manufacturing efficiency. this article is perfect for engineers, designers, and anyone interested. A lifter is a mechanism that is often used in plastic injection molds or die casting molds. it is employed to handle specific shapes or structures within the mold, often utilized for creating internal undercuts or complex features in a product. the purpose of a lifter is to enable the successful ejection of the molded part from the mold.

The Lifters For Plastic Injection Mold Ecomolding

Comments are closed.