Mitsubishi Cooperative Steam Turbine Condensing Steam Turbine

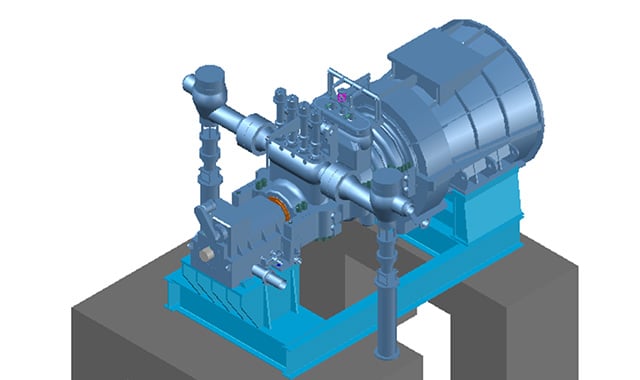

Mitsubishi Cooperative Steam Turbine Condensing Steam Turbine Mitsubishi power steam turbines are a result of more than a century of r&d and manufacturing experience. our highly reliable and efficient steam turbines have undergone strict in house testing and quality management procedures to meet the diverse requirements of our global customer base. we offer a comprehensive lineup of small and mid sized. Single casing. output. up to 200 mw class. main steam conditions. up to 13.7 mpa up to 566°c. revolutions per minute. 3,000 min 1 (50 hz) 3,600 min 1 (60 hz) information about small mid sized condensing turbines from mitsubishi power.

Mitsubishi Condensing Type Steam Turbines Lifetime Inspections Mitsubishi power has a comprehensive lineup of steam turbines, with the flexibility to customize each turbine according to the needs of its customers. our many years of r&d coupled with our rich manufacturing experience ensure that we deliver high performance and highly reliable steam turbines to our customers. On condensing if the condenser is rigidly fixed to the baseplate. if the turbine operates non condensing and the condenser is rigidly fixed, the condenser would grow upwards from the hot. r exhaust temperatures and would try to move the turbine upw. rds. this would ultimately lead to one of the components failing. a remedy to this issue is. After passing through the final stage, the steam is directed into a condenser, where it is cooled and condensed back into water. this process creates a vacuum at the turbine’s exhaust, which further increases the pressure drop across the turbine, allowing for greater energy extraction. applications and benefits. Hp steam is exhausted at vacuum conditions and is condensed against a cooling utility. steam turbines typically rotate at 3,000–15,000 rpm. at that speed, water droplets can form and unbalance the turbine blades, causing severe mechanical damage. bpsts can usually operate safely at up to 3% moisture (i.e., a minimum steam quality of 97%).

Mitsubishi Condensing Type Steam Turbines Lifetime Inspections After passing through the final stage, the steam is directed into a condenser, where it is cooled and condensed back into water. this process creates a vacuum at the turbine’s exhaust, which further increases the pressure drop across the turbine, allowing for greater energy extraction. applications and benefits. Hp steam is exhausted at vacuum conditions and is condensed against a cooling utility. steam turbines typically rotate at 3,000–15,000 rpm. at that speed, water droplets can form and unbalance the turbine blades, causing severe mechanical damage. bpsts can usually operate safely at up to 3% moisture (i.e., a minimum steam quality of 97%). Condensing turbines are widely used in power generation, where maximum efficiency is required. non condensing turbines: also known as back pressure turbines, these turbines exhaust steam at a pressure higher than atmospheric pressure. the exhaust steam can be used for heating or other industrial processes. A few of the turbine suppliers advocate a redundancy. when the steam turbine is not in service, a separate spray curtain is required to be incorporated in the steam surface condenser to prevent high temperature bypass steam from migrating into the steam turbine thereby heating the exhaust hood.

Mitsubishi Power Small Mid Sized Condensing Turbines Condensing turbines are widely used in power generation, where maximum efficiency is required. non condensing turbines: also known as back pressure turbines, these turbines exhaust steam at a pressure higher than atmospheric pressure. the exhaust steam can be used for heating or other industrial processes. A few of the turbine suppliers advocate a redundancy. when the steam turbine is not in service, a separate spray curtain is required to be incorporated in the steam surface condenser to prevent high temperature bypass steam from migrating into the steam turbine thereby heating the exhaust hood.

Comments are closed.