One Picture To Understand The Structure Of An Injection Mold My Xxx

One Picture To Understand The Structure Of An Injection Mold Bo li. injection molding is a kind of processing method used in batch production of some complicated parts. the working principle is that a material is heated to its melting point and then forced through an injection port to fill a formed cavity at high pressure. as the material cools, it will solidify into the shape of the cavity and become. X. mold base. picture the mold as a grand edifice—a structure poised for manufacturing mastery. at its very foundation stands the silent but solid element, the mold base. this unassuming but indispensable component provides not only support but a blueprint for the entire ensemble, dictating the form and function of every subsequent part.

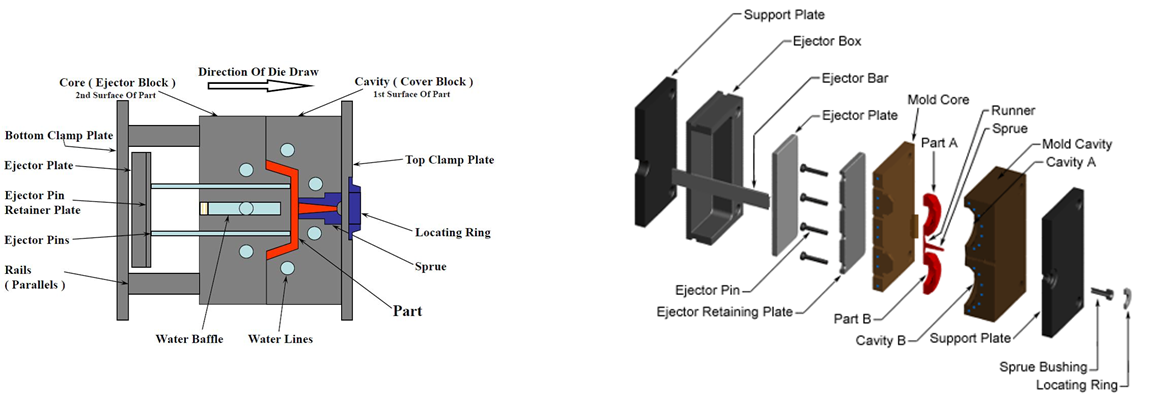

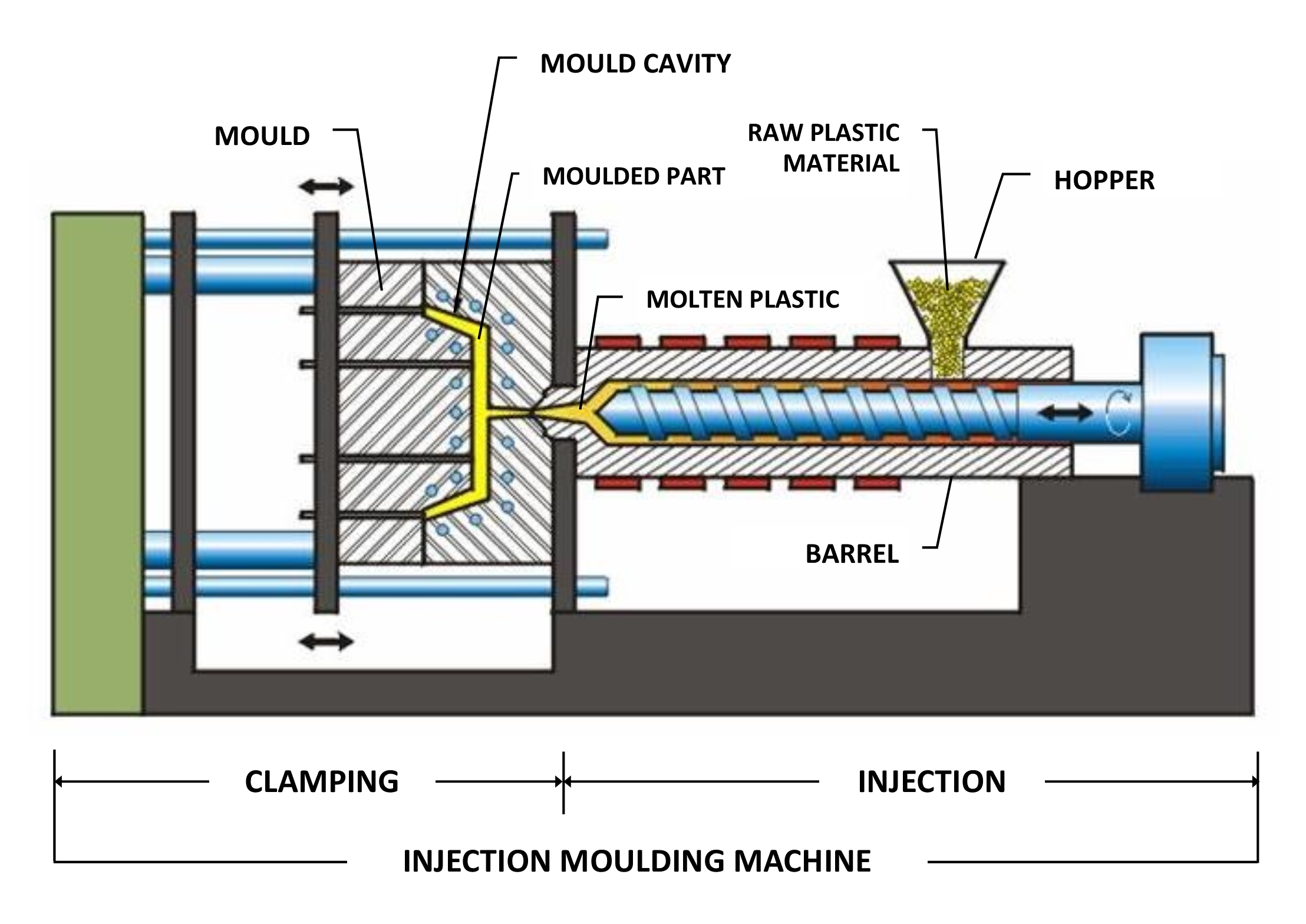

One Picture To Understand The Structure Of An Injection Mold My Xxx A comprehensive introduction to injection mold components and the structure from a 20 year experienced expert from a big mold making factory. The core and cavity have several functions in the injection molding process, such as: forming the shape and size of the molded part. the core and cavity determine the geometry, dimensions, and features of the molded part. they also affect the appearance, strength, and functionality of the part. Injection molding injection molding is an established manufacturing technology with a long history, but it is constantly being refined and improved with new technological advancements. below is a quick rundown of the key advantages and disad vantages of injection molding to help you understand whether it is the right solution for your application. Understanding the main structure and components of the injection molding machine is essential to optimize the production process, improve product quality and reduce maintenance costs. let’s introduce the basic components of the injection molding machine and its functions, so that readers have a clear understanding of this complex machinery.

How To Calculate Cycle Time Of Injection Moulding At Stephen Gilbert Blog Injection molding injection molding is an established manufacturing technology with a long history, but it is constantly being refined and improved with new technological advancements. below is a quick rundown of the key advantages and disad vantages of injection molding to help you understand whether it is the right solution for your application. Understanding the main structure and components of the injection molding machine is essential to optimize the production process, improve product quality and reduce maintenance costs. let’s introduce the basic components of the injection molding machine and its functions, so that readers have a clear understanding of this complex machinery. Half mold structure 1. as shown in the figure below, the cavity is composed of two inclined slides located on one side of the fixed mold. when the mold is opened, under the action of the pull hook 1 and the spring, the inclined slider 3 runs along the inclined chute to complete the lateral parting. Understanding the structure and functions of an injection molding machine is of great significance for optimizing the production process, improving product quality, and reducing production costs. this article will delve into the structural components and various functions of injection molding machines, providing a comprehensive reference guide.

Comments are closed.