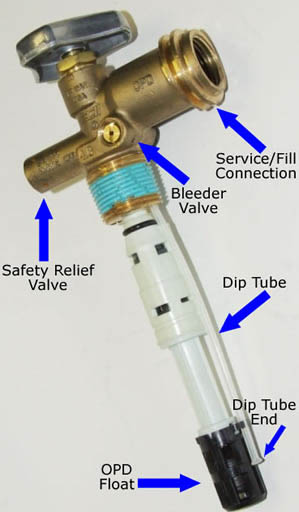

Opd Propane Tank Valve Diagram

Opd Propane Tank Valve Diagram The opd valve diagram is a graphical representation of the opd (overfill protection device) valve, which is an important safety feature in propane tanks. the diagram illustrates the various components of the valve and how they work together to ensure safe propane storage and usage. the opd valve is designed to prevent overfilling of propane. This video shows the disassembly of an opd, (overfill protection device) valve from a 20# propane tank. i also discuss the parts and how they work. stay tun.

Propane Tank Opd Valve Disassembly How It Works What Can Be The opd valve diagram is a visual representation of how an overfill prevention device (opd) valve works. this valve is used in propane cylinders to prevent overfilling and ensure the safe transportation and storage of propane gas. the diagram shows the various components of the opd valve and how they interact to regulate the flow of propane. The propane tank valve diagram illustrates the various components of this essential part. at the top of the diagram, you’ll find the main valve, which is typically made of brass or another durable material. the main valve has an integrated handle that allows users to turn it on or off, controlling the flow of propane. Opd stands for "overfilling prevention device" or "overfill protection device" and is required on all 4 to 40 pound dot cylinders in vapor service. the opd valve is simply a protective device that, as the name implies, prevents overfilling of a propane cylinder. before any propane cylinder (4 to 40#) can be filled with propane, the cylinder. The valves on consumer propane cylinders are not solely service valves. they incorporate all the required safety components, such as the opd valve, as well as being the point at which the cylinder is refilled. these components are integrated within the valve itself and consist of fixed liquid level gauge, service valve (handwheel), fill valve.

The Ultimate Guide To Understanding Propane Tank Valve Diagrams Opd stands for "overfilling prevention device" or "overfill protection device" and is required on all 4 to 40 pound dot cylinders in vapor service. the opd valve is simply a protective device that, as the name implies, prevents overfilling of a propane cylinder. before any propane cylinder (4 to 40#) can be filled with propane, the cylinder. The valves on consumer propane cylinders are not solely service valves. they incorporate all the required safety components, such as the opd valve, as well as being the point at which the cylinder is refilled. these components are integrated within the valve itself and consist of fixed liquid level gauge, service valve (handwheel), fill valve. This is a statement propane cylinder users sometimes make following the exchange or re filling of their bottle. the bottle feels heavier and obviously is filled with propane but opening the valve produces no escaping gas. opd valves are designed so that propane will not flow from the service valve unless it is hooked up to a hose end connection. National code requires propane cylinders from 4 40 pounds have an opd. "over fill protection device" (opd) valves are manufactured with a specific shape to quickly identify them from older valves that do not have the opd feature. notice on the picture provided below. the left image is of the older style valve and the three cornered handle on.

The Ultimate Guide To Understanding Propane Tank Valve Diagrams This is a statement propane cylinder users sometimes make following the exchange or re filling of their bottle. the bottle feels heavier and obviously is filled with propane but opening the valve produces no escaping gas. opd valves are designed so that propane will not flow from the service valve unless it is hooked up to a hose end connection. National code requires propane cylinders from 4 40 pounds have an opd. "over fill protection device" (opd) valves are manufactured with a specific shape to quickly identify them from older valves that do not have the opd feature. notice on the picture provided below. the left image is of the older style valve and the three cornered handle on.

Propane Tank Valve Parts Diagram

Comments are closed.