Ppt System Benefits With Ecm Pumps Hydronic System Efficiency

Ppt System Benefits With Ecm Pumps Hydronic System Efficiency Example: 100,000 btu hr. boiler & (1) .5 amp 115v pump system .5 amp x 115v = 60 watts divided by100,000=1,666btu’s hr. per watt used if we use a 30 watt pump divided by 100,000=3,333btu’s hr. per watt used now imagine multiple pump systems!. The system today exceeds this seemingly implausible goal, drawing just one fifth of that 300 watt target – 57 watts – thanks to a revolutionary new ecm circulator from grundfos pumps. first introduced by grundfos in europe roughly a decade ago, the alpha™ is an energy optimized, 115 volt circulator that automatically and continuously.

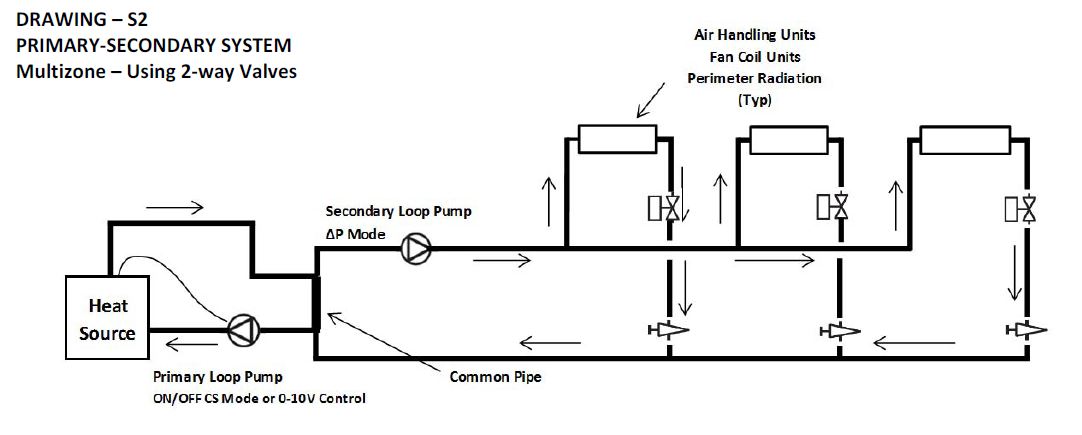

Using Ecm Smart Pumps In Secondary Hydronic Systems Rld Users can measure energy consumption and usage on a competitive pump basis based on individual pumps’ specific hi rating — the higher the energy rating, the more efficient the pump. ecm technology in hvac applications can decrease energy usage by as much as 75%. for example, a standard efficiency circulator has a typical er of 48 to 50. A primary secondary system has a primary pump or pumps circulating the heat cool source, and a secondary pump or pumps circulating the terminal units and distribution piping. the most important part of this hydronic piping system is the common pipe, which separates the two pumping systems and is characterized by a very low pressure drop in relation to the pressure drop in either circuit. Using b&g ecocirc ® xl ecm smart circulator pumps in primary hydronic systems. these function in two different ways, though the application is identical: most receive a 0 10v signal from the boilers indicating what speed the boiler wants the pump to run (laars vari prime, for example). the boiler itself is determining this speed based on the. The grundfos advanced, variable speed, "smart" pumps for hydronic heating systems can reduce pumping energy use by 80%. photo: grundfos usa. click on image to enlarge. for the past couple years, i've been helping all soul's church in west brattleboro, vermont, save energy. while developing a plan to improve the performance of the building envelope of this early 1970s, heavily glazed and.

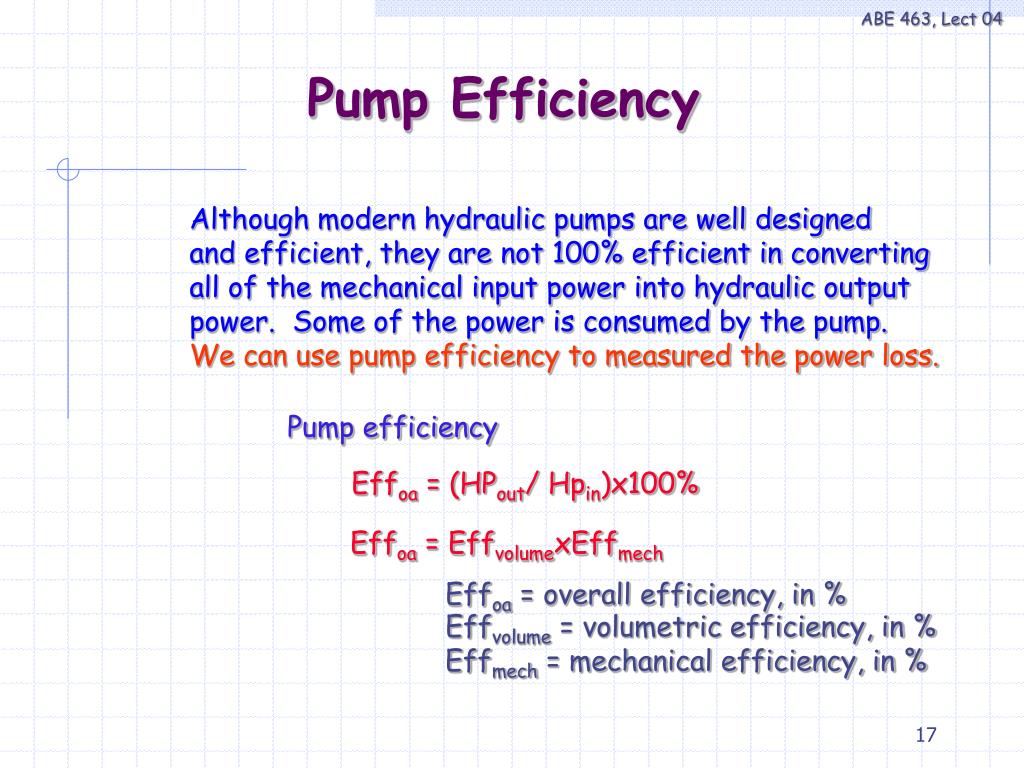

Ppt Abe 463 Electrohydraulic Systems Powerpoint Presentation Free Using b&g ecocirc ® xl ecm smart circulator pumps in primary hydronic systems. these function in two different ways, though the application is identical: most receive a 0 10v signal from the boilers indicating what speed the boiler wants the pump to run (laars vari prime, for example). the boiler itself is determining this speed based on the. The grundfos advanced, variable speed, "smart" pumps for hydronic heating systems can reduce pumping energy use by 80%. photo: grundfos usa. click on image to enlarge. for the past couple years, i've been helping all soul's church in west brattleboro, vermont, save energy. while developing a plan to improve the performance of the building envelope of this early 1970s, heavily glazed and. It gets sweeter though, the 45 watts consumption of an ecm pump is at full speed and these are variable speed pumps. how do they vary speeds? some are delta t pumps and vary speed based on supply and return temperatures to maintain a constant delta t, usually 20 degrees in most systems. these pumps provide a benefit way beyond the electrical. Dec. 5, 2014. one of the latest advancements has been the expanding reach of sensorless and electronically commutated motor (ecm) pumps. just a few years ago, a conversation about optimal hydronic system performance likely would have veered toward chiller or boiler type and efficiency, building envelope, system design, and or key components.

Using Ecm Smart Pumps In Secondary Hydronic Systems Rld It gets sweeter though, the 45 watts consumption of an ecm pump is at full speed and these are variable speed pumps. how do they vary speeds? some are delta t pumps and vary speed based on supply and return temperatures to maintain a constant delta t, usually 20 degrees in most systems. these pumps provide a benefit way beyond the electrical. Dec. 5, 2014. one of the latest advancements has been the expanding reach of sensorless and electronically commutated motor (ecm) pumps. just a few years ago, a conversation about optimal hydronic system performance likely would have veered toward chiller or boiler type and efficiency, building envelope, system design, and or key components.

Comments are closed.