Reduce Your Tooling Costs With Mass Production 3d Printing

Reduce Your Tooling Costs With Mass Production 3d Printing Youtube Wondering how you can reduce your manufacturing costs? discover how mass production 3d printing can eliminate the need for costly and time consuming traditio. Slant 3d has been doing mass production 3d printing for years. it is an ideal way for companies to reduce tooling expenses on the pnl or amoritization the balance sheet. but what is it exactly, and how do we do it?how we got started in mass production 3d printingslant 3d started as a project inside of a product design company. there had been a product created that intially was expected to be.

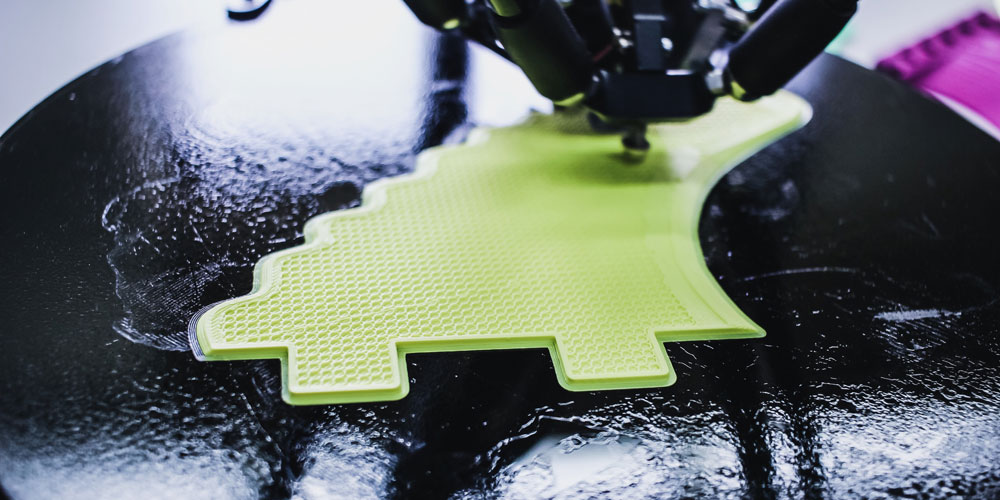

How To Reduce Production Costs With 3d Printing Jcr3d Smart Printer For example, liberty electronics, a contract manufacturing shop producing high end assemblies for the military and aerospace industries in pennsylvania, saved 85% of a custom tool ’s cost by 3d printing it in house instead of outsourcing. inventory is another area where manufacturers can dramatically reduce expenditure with 3d printing. Mass production using 3d printing can greatly reduce time to market by avoiding traditional tooling methods, cutting lead times on prototypes and end use parts. mass production with 3d printing doesn’t always mean directly printing end use parts, but creating cheap, custom tooling. an example is custom 3d printed molds for injection molding. Low tooling costs. 3d printing production tools, such as jigs and fixtures, can significantly cut manufacturing costs. jigs and fixtures are frequently outsourced to outside vendors, who cnc mill or hand weld and assemble them. 3d printing jigs and fixtures in house can be a considerably faster and less expensive option. spare parts printed in 3d. Scale up with high volume 3d printing solutions. we understand the importance of scalability and efficiency in mass production. equipped with advanced 3d printing technologies, we handle large order requests with fast turnaround times and competitive pricing. our optimized production process ensures efficiency without compromising quality.

How To Lower Your Mass Production 3d Printing Costs Youtub Low tooling costs. 3d printing production tools, such as jigs and fixtures, can significantly cut manufacturing costs. jigs and fixtures are frequently outsourced to outside vendors, who cnc mill or hand weld and assemble them. 3d printing jigs and fixtures in house can be a considerably faster and less expensive option. spare parts printed in 3d. Scale up with high volume 3d printing solutions. we understand the importance of scalability and efficiency in mass production. equipped with advanced 3d printing technologies, we handle large order requests with fast turnaround times and competitive pricing. our optimized production process ensures efficiency without compromising quality. Conclusion. 3d printing stands as a transformative force in the manufacturing industry, offering unprecedented opportunities to reduce costs across various stages of production. from minimizing material waste to enabling on demand and localized manufacturing, the cost saving potentials are vast and diverse. 6 ways additive affects machining read more. learn about metal 3d printing for production at imts read more. (2) thyssenkrupp bilstein’s ohio suspension plant uses raise3d printers as a fast and economical way to obtain custom end effectors for robots. (3) pmt shielding solutions controls metal coating processes for electronics components by.

Comments are closed.