Robot Dispensing In Automotive Aerospace Electronics Consumer

Robot Dispensing In Automotive Aerospace Electronics Consumer Arsenal products’ robotic adhesive dispensing systems leverage the accuracy and repeatability of a cobot or robot. a cobot or robot paired with precision dispensing controls ensures a customer process is up and running quickly… in hours, not days, weeks, or months. programming is very simple on many of the most modern robots and cobots. Despite these costs, dispensing robots are widely used in electronics assembly, medical device manufacturing, aerospace and general assembly operations. they can perform a wide variety of operations, including: • dispensing dots of solder paste • forming of in place gaskets • filling of areas and potting of modules • encapsulating.

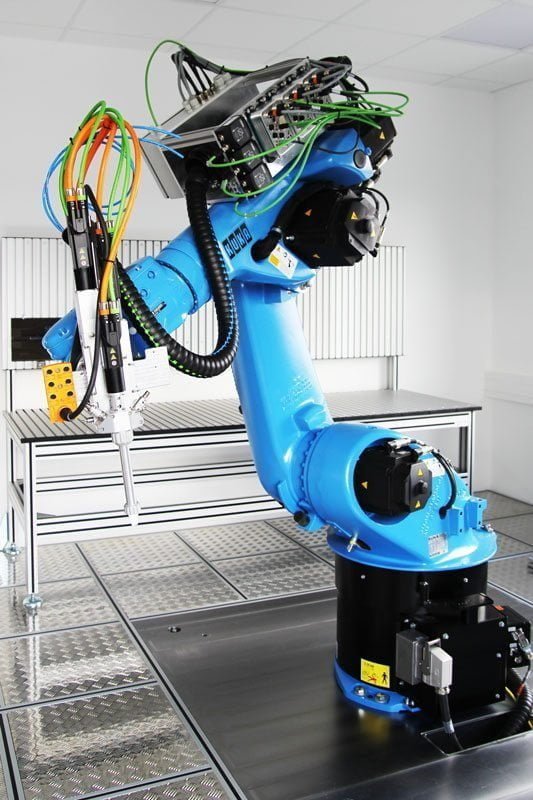

Robotic Dispensing System With Four Hot Melt Jetting Valves Intertronics The dispensing equipment can be operated manually as a stand alone system, or it can be integrated with a robot for fully automated dispensing. materials can be dispensed from 5 gallon buckets or 55 gallon drums. “in a typical non aerospace application, we might dispense 20 to 30 milliliters per shot,” says ripberger. To list a few more benefits, dispensing robots: increase throughput. increase process reliability and repeatability. reduce unwanted dispensing. reduce manufacturing time. guaranty accuracy, irrespective of dispensing surface. increase the roi. remove safety issues in manual dispensing. What do these robots look like? as mentioned, robotic dispensing units can take many forms. among the most commonly used are desktop or benchtop units, which usually have a work area ranging from 200 mm by 200 mm to 400 mm by 400 mm. such units are often used to increase productivity without adding labor, or improve precision in dispensing. A 3 axis fluid dispensing robot can also be applied for adhering anode, separator, and cathode layers for ev battery production. robotic dispensing systems, such as the nordson efd gv series gantry dispensing robot, provide the conveyor fed assembly required by li ion and hydrogen fuel cell electric car battery production. the robot's 3d motion.

New Kuka Robot For Dispensing Tests Capri Systec Ltd What do these robots look like? as mentioned, robotic dispensing units can take many forms. among the most commonly used are desktop or benchtop units, which usually have a work area ranging from 200 mm by 200 mm to 400 mm by 400 mm. such units are often used to increase productivity without adding labor, or improve precision in dispensing. A 3 axis fluid dispensing robot can also be applied for adhering anode, separator, and cathode layers for ev battery production. robotic dispensing systems, such as the nordson efd gv series gantry dispensing robot, provide the conveyor fed assembly required by li ion and hydrogen fuel cell electric car battery production. the robot's 3d motion. Equipment adhesives expertise = total assembly solutions. loctite ® automated robotic dispensing systems are cost effective solutions designed to simplify the dispensing of adhesives and sealants onto various surface configurations, ranging from simple to complex. dispensing robots allow manufacturers to repeatedly and reliably dispense. Loctite ® automated robotic dispensing systems are designed to simplify the dispensing of adhesives and sealants onto complex surface configurations. dispensing robots allow manufacturers to repeatedly and reliably dispense patterns of liquid material on a programmed basis, resulting in improved process efficiencies, minimal material waste and reduced manufacturing costs.

Comments are closed.