Silicone 3d Printing How It Works Benefits And Applications

Silicone 3d Printing How It Works Benefits And Applications 2022 In 3d printing, manufacturers are mostly interested in liquid silicone rubber (lsr), a highly stable elastomer resistant to extreme temperatures and environments. material properties of silicone include: excellent thermal stability. available in different hardnesses. water resistance and suitability as sealant. Silicone 3d printing is expected to have a significant impact on the industry and represents an important milestone in the development of 3d technology. according to a study by precision business insight, the silicone 3d printing market is estimated to reach $1,590.3 million in 2021 and is expected to grow at a compound annual growth rate of 19.

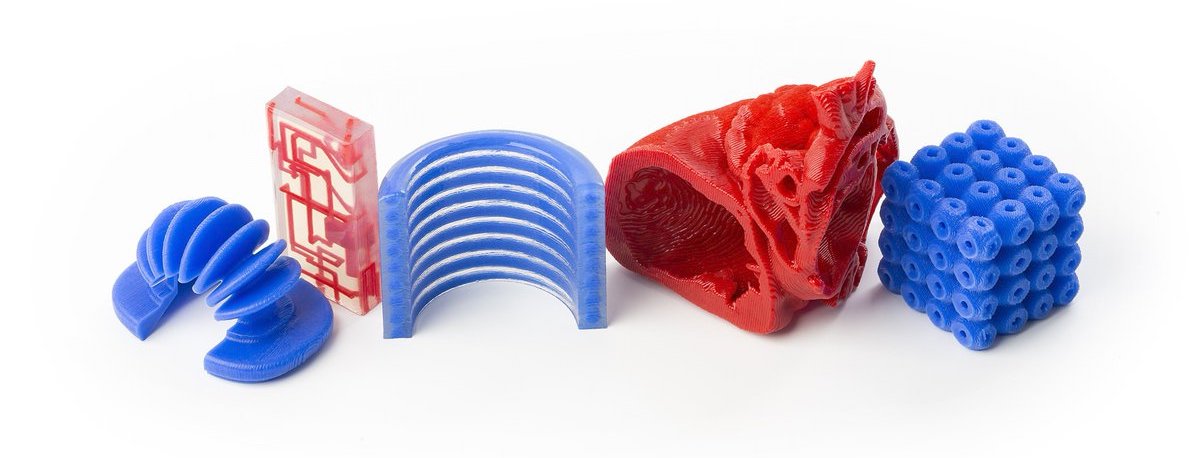

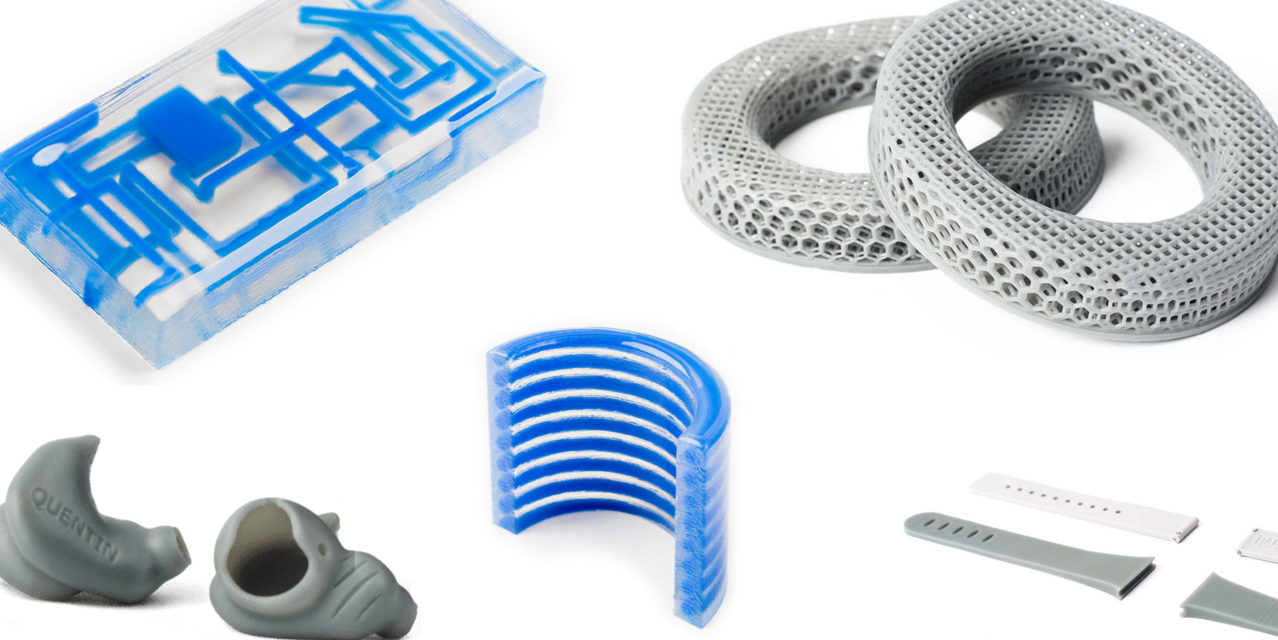

Silicone 3d Printing How It Works Benefits And Applications 2022 Where silicone 3d printing really comes into its own is producing intricate geometries, forms, and shapes, especially when moulds and casts are too time consuming and complex to produce, saving you both time and money. soft silicones are suited to: non marring grippers. print in place soft components. vibration and shock dampers. Silicone 3d printing – the ultimate guide. by carolyn schwaar. updated oct 5, 2023. still a challenging material to 3d print, silicone is now more accessible as new 3d printers and materials enter the market. Silicone 3d printing finds applications in various industries. in the medical sector, it is used for surgical implants and prostheses. soft robotics is another field that benefits from silicone 3d printing, as it is suitable for producing soft robotic components such as grippers. The reason why silicone works with these 3d printers is that the material is blended with other photosensitive resins, making it curable. image source: prayasta. part 3. silicone 3d printing why to 3d print silicone? despite the material properties of silicone, there are many benefits 3d printing silicone. reduce cost.

A Beginnerтащs Guide To юааsiliconeюаб юаа3dюаб юааprintingюаб Amfg Silicone 3d printing finds applications in various industries. in the medical sector, it is used for surgical implants and prostheses. soft robotics is another field that benefits from silicone 3d printing, as it is suitable for producing soft robotic components such as grippers. The reason why silicone works with these 3d printers is that the material is blended with other photosensitive resins, making it curable. image source: prayasta. part 3. silicone 3d printing why to 3d print silicone? despite the material properties of silicone, there are many benefits 3d printing silicone. reduce cost. An important step in healthcare. in the medical field, silicone 3d printing is used in the making of suture training supports, in the production of orthopedic parts (podology, orthoprosthesis), but also of medical implants for epithetics or ostomy bag wafer for example. silicone printing for medical – orthopedic device. Direct silicone 3d printing is now finally easily accessible and there are many other ways to leverage the benefits of 3d printing to produce silicone or silicone like parts. request a free sample part printed in silicone 40a resin or formlabs’ flexible and elastic sla materials or speak with a 3d printing expert today to find the right solution for your application.

Silicone 3d Printing How It Works Benefits And Applications An important step in healthcare. in the medical field, silicone 3d printing is used in the making of suture training supports, in the production of orthopedic parts (podology, orthoprosthesis), but also of medical implants for epithetics or ostomy bag wafer for example. silicone printing for medical – orthopedic device. Direct silicone 3d printing is now finally easily accessible and there are many other ways to leverage the benefits of 3d printing to produce silicone or silicone like parts. request a free sample part printed in silicone 40a resin or formlabs’ flexible and elastic sla materials or speak with a 3d printing expert today to find the right solution for your application.

Comments are closed.