Sla Vs Fdm 3d Technologies Compared Xometry Europe

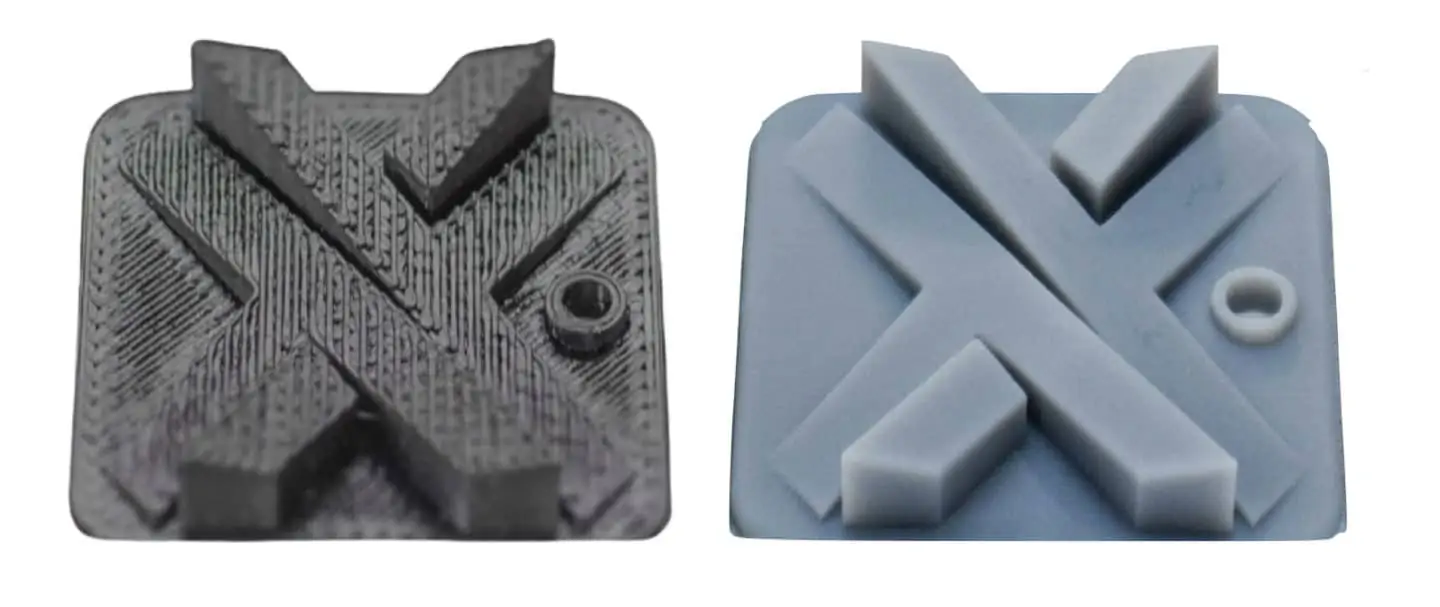

Sla Vs Fdm 3d Technologies Compared Xometry Europe Sla 3d printing. a limited selection of materials: sla technology only utilises thermosetting resins which make the technology very limited with build materials. biocompatible and food grade materials: sla is one of the best technologies to print medical implants or food containers, with resins such as true silicone. fdm 3d printing. Sla produces parts with excellent surface finish and highly detailed features and can print quicker when compared to fdm. fdm on the other hand is cheaper, has more material options, and produces stronger parts. the main advantage of using sla is the ability to create high detail parts, whereas fdm produces functional parts with high strength.

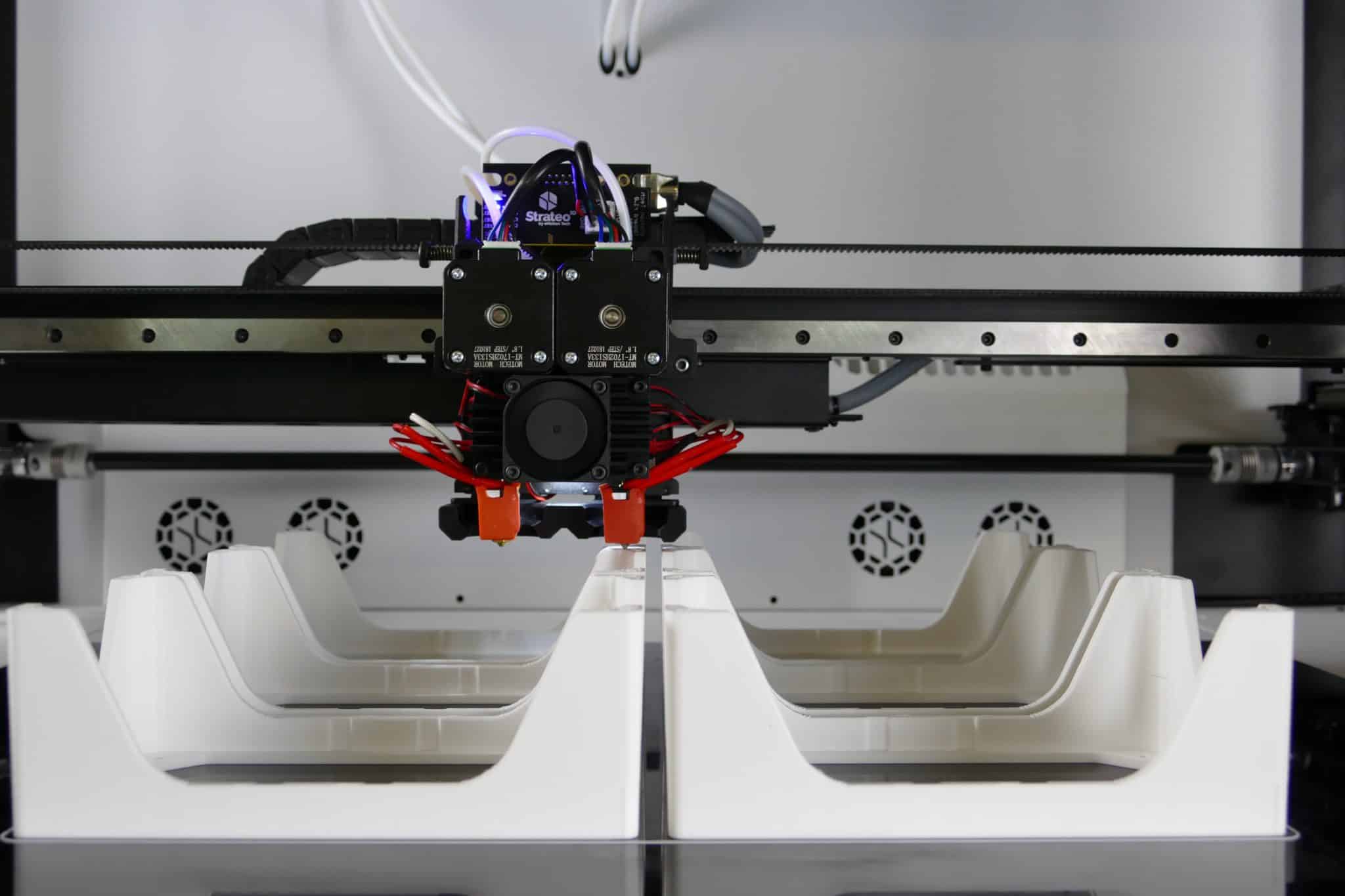

Sla Vs Fdm 3d Technologies Compared Xometry Europe This article compares two 3d printing technologies, sla vs. fdm, regarding various aspects for both industrial and desktop applications. 3d printing. hp multi jet fusion (mjf) fused deposition modeling (fdm) selective laser sintering (sls) stereolithography (sla) direct metal laser sintering (dmls) polyjet; formative manufacturing. injection moulding; urethane casting; die casting; additional services. surface finishing; high volume manufacturing; rapid prototyping; industries. 1. durability. when it comes to simple durability, fdm is much better as a solution than sla resin. it is far more robust, easier to use, and better for customization. fdm is the only way a person should be going when it comes to finding a solution that is going to last for a long time to come. Sla materials are uniquely formulated, as opposed to the industry standard thermoplastics used in fdm and sls 3d printing. one of the main benefits of sla lies in this material versatility — manufacturers have created innovative sla photopolymer resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial.

Comments are closed.