Sls Vs Fdm Vs Sla 3d Printing Key Differences App

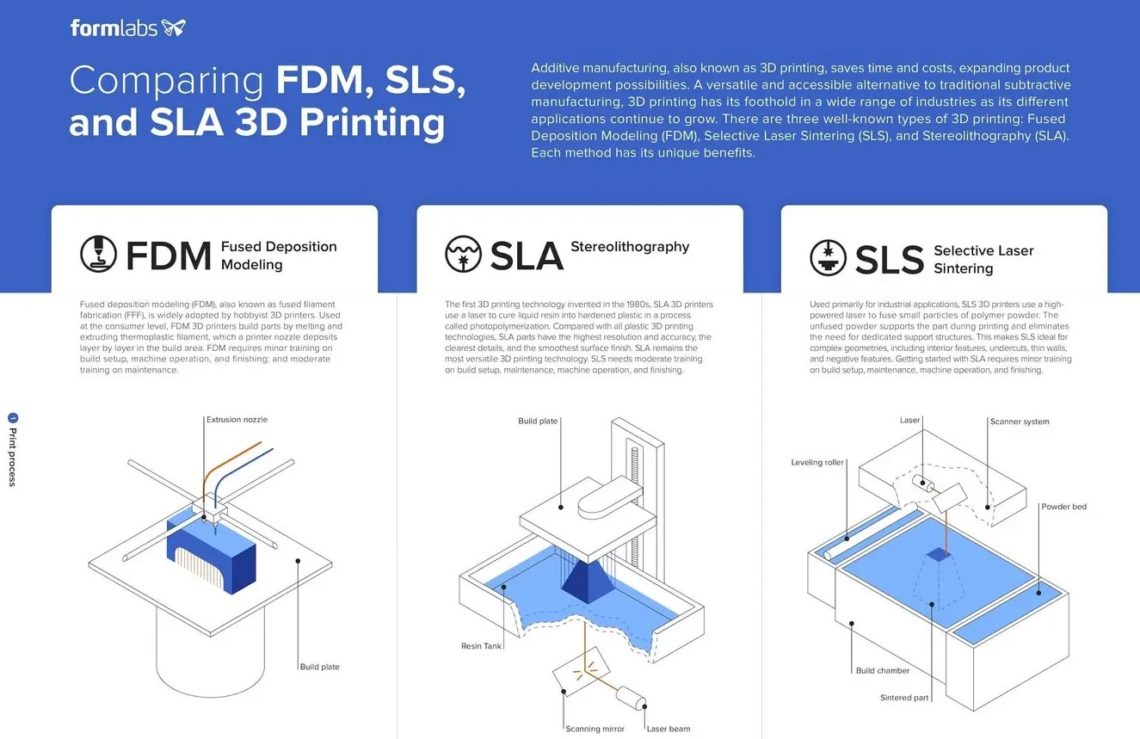

Comparing Properties Of Fdm Sls And Resin 3d Printing Plastics In this article, we will explore the key differences and applications of these three popular 3d printing technologies. sls 3d printing. sls, or selective laser sintering utilizes a high power laser to sinter polymer powder, eliminating the need for support structures. nylon is a commonly used material in sls, offering design freedom and. Sla materials are uniquely formulated, as opposed to the industry standard thermoplastics used in fdm and sls 3d printing. one of the main benefits of sla lies in this material versatility — manufacturers have created innovative sla photopolymer resin formulations with a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial.

Design And Validation Fdm Vs Sla Vs Sls 3d Printing Youtub Fdm produces parts by melting thermoplastic filament using an extrusion. but sls produced parts by sintering powdered filament using a high power laser. at the same time, sla produces parts through the uv curing process. the operation principles make the 3d printing technologies different from each other. Among the array of 3d printing technologies available, fdm (fused deposition modeling), sla (stereolithography), and sls (selective laser sintering) are among the most popular and widely used. Designing for fdm. to create models for fdm 3d printers you need to use a computer aided design (cad) or a 3d computer graphics software.this technology has some troubles with hollow parts, undercuts and overhangings, so support structures like boxes, ceilings or webs must be designed and fabricated, in order for the models to be printed. Sls systems are more expensive than fdm systems because of the complex technologies and materials involved. sls systems start at around $10,000 and can go as high as $100,000 or more. desktop or hobbyist level fdm systems can be purchased for a few hundred dollars, while industrial fdm printers start around $15,000.

Comments are closed.