Starting Air System Knowledge Of Sea

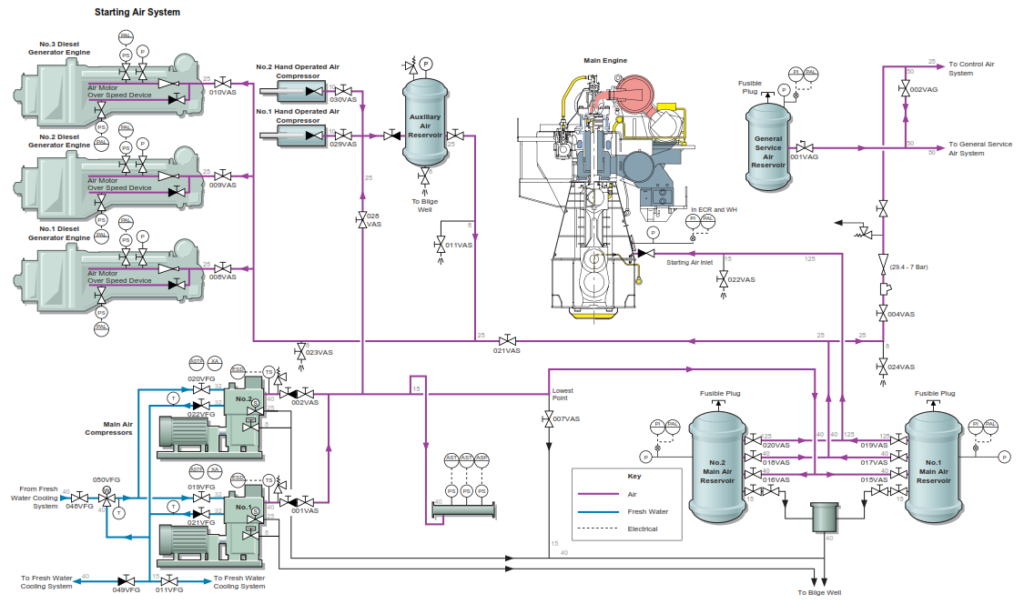

Starting Air System Knowledge Of Sea Starting air system. the starting air system is supplied by two main starting air compressors that supply two 5.0m3 starting air receivers. the compressors are of the two stage reciprocating type and are cooled by fresh water from the fresh water cooling system. a three way temperature controlled valve is used to regulate the flow of water to. A) preheat the engine cooling water system to at least 20°c but preferably to 70°c. note: the engine must not be started if the jacket cooling water temperature is below 20°c. b) start one of the main fresh water cooling pumps. c) start one of the main sea water cooling pumps. d) ensure that the cooling water system pressures are correct and.

How Marine Engine Air Starting System Work Starting Air System Y There should be a minimum overlap of 15 degrees provided and the ideal condition should be between 20 degrees and 90 degrees. for a 4 cylinder 2 stroke engine the firing interval is 90 degrees (360 4) and if the starting air period is 115 degrees then the total overlap period would be the difference between the two, i.e. 115 90=25 degrees. Ø start the engine lub oil pumps, engage turning gear and turn the engine ensuring indicator cocks are open. Ø jacket water heating should be on ensuring the engine is warmed through, circulated by circulating pump. Ø the fuel oil booster pumps should also be running, circulating fuel around the system. C) pressurise the air systems and ensure that the pressures are correct d) ensure compressed air is available at the exhaust valve ‘air spring’ closing cylinders. related read: 8 things marine engineers must know about starting air system on ship. 2. lubricating oil systems. a) check the oil level in the main engine sump and replenish if. By anish march 9, 2021 main engine, videos. the video shows the line diagram for main engine air starting system which comprises of – air bottle to provide 30 starting air, pilot valve to start the operation, turning gear interlock, automatic air start valve, air distributor, and cylinder head starting air valve.

Understanding A Marine Diesel Engine Starting Air System C) pressurise the air systems and ensure that the pressures are correct d) ensure compressed air is available at the exhaust valve ‘air spring’ closing cylinders. related read: 8 things marine engineers must know about starting air system on ship. 2. lubricating oil systems. a) check the oil level in the main engine sump and replenish if. By anish march 9, 2021 main engine, videos. the video shows the line diagram for main engine air starting system which comprises of – air bottle to provide 30 starting air, pilot valve to start the operation, turning gear interlock, automatic air start valve, air distributor, and cylinder head starting air valve. Ships compressed air systems are usually divided into one or more of the following: main and auxiliary engine starting air system (high pressure). service air. control air. instrument air. deck services; low pressure (5 8 bar) air may be supplied by either individual compressors or pressure reducing valves fitted within the high pressure circuit. Starting air system. the starting air system is supplied by two main starting air compressors that supply two 5.0m3 starting air receivers. the compressors are of the two stage reciprocating type and are cooled by fresh water from the fresh water cooling system. a three way temperature controlled valve. jun 20, 2023 by admin in engine room.

Comments are closed.